conductive electrode

A technology of conductive electrodes and conductive substrates, which is applied in the input/output process of electrical digital data processing, instruments, and data processing, etc., can solve the problem of side erosion of metal conductive electrodes 10, large wire diameter impedance values of electrode lines 14, and reduce conductive electrodes. Product yield and other issues to achieve the effect of reducing severe side erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

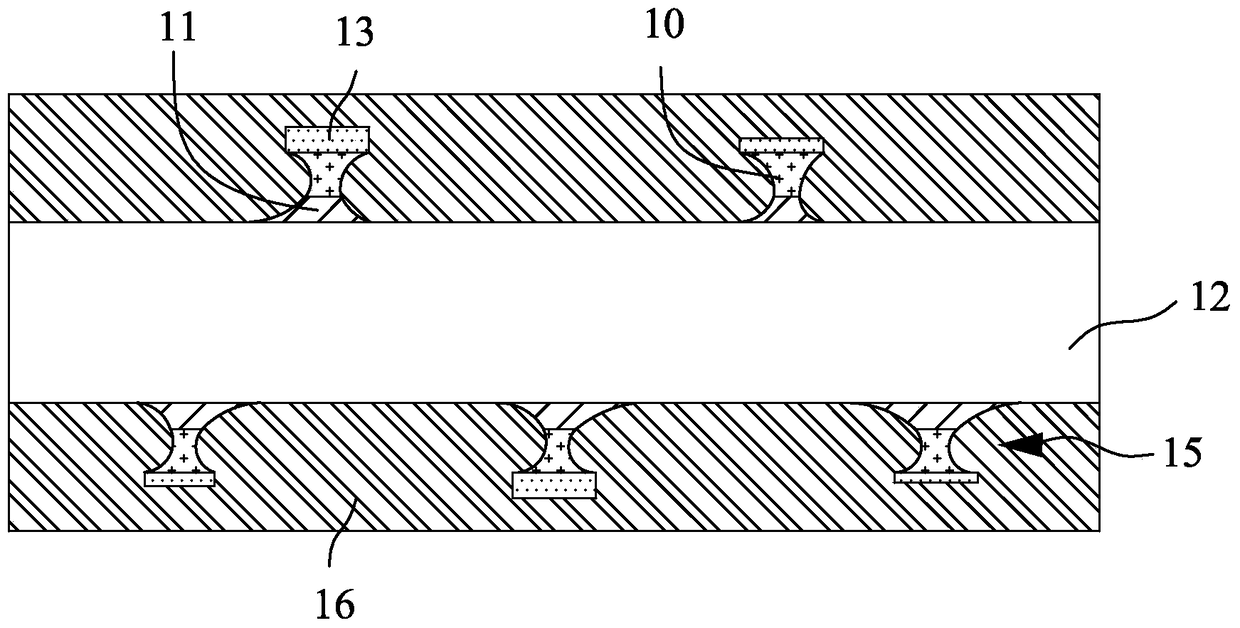

[0044] In order to further have a clearer and more detailed understanding and understanding of the structure, use and features of the present invention, a preferred embodiment is given, and the details are as follows in conjunction with the drawings:

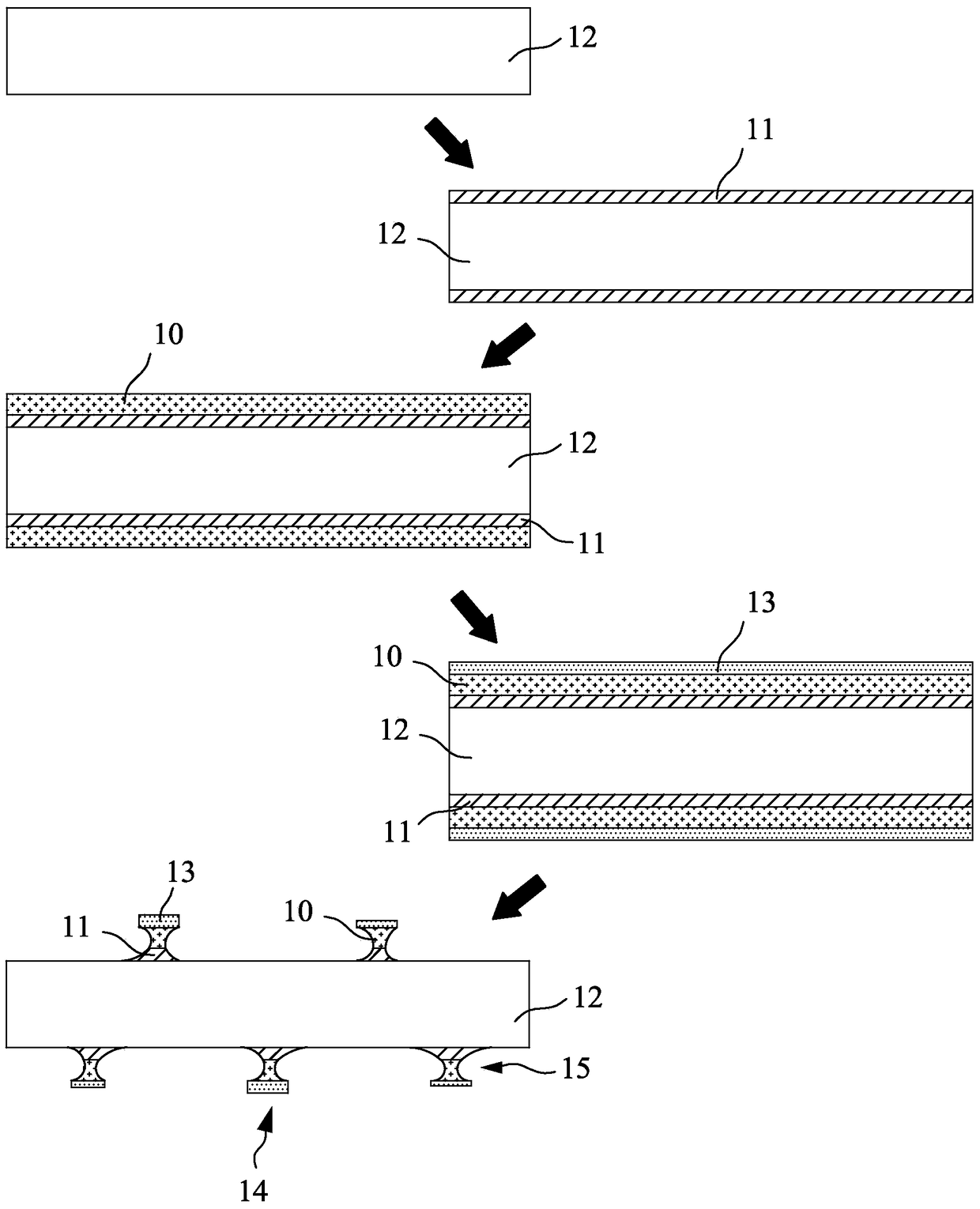

[0045] see Figure 4A to Figure 4B As shown, in a preferred embodiment of the conductive electrode for touch control of the present invention, the manufacturing steps are described as follows.

[0046] (A) select a preset base material, form a base material layer 2 by the base material, the base material layer 2 can be made of soft material or glass plate, and the soft material is made of poly Polyethylene terephthalate (PET), polymethyl methacrylate (PMMA), polycarbonate (PC), polyphenylene sulfone (PPSU), polyethyleneimine (PEI) or polyimide ( PI) made of one of them;

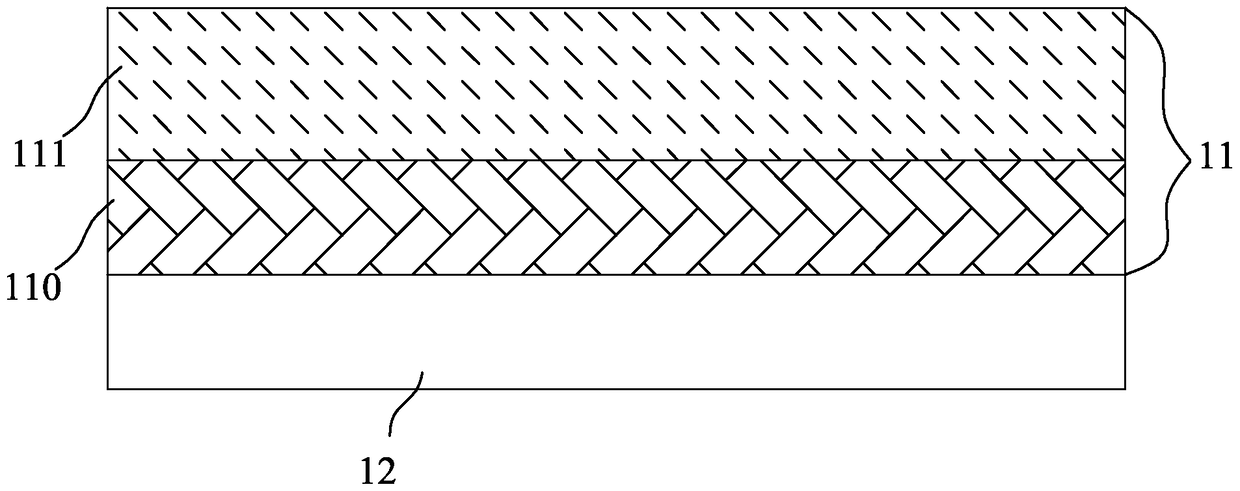

[0047] (B) At least one conductive adhesion layer 3 is formed on the surface of the base material layer 2, wherein the thickness of the adhesion layer 3 is b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com