Garlic planting device

A material roller and frame technology, which is applied in the field of agricultural machinery and tools, can solve the problems of low operating efficiency, difficulty in ensuring the distance between plants, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

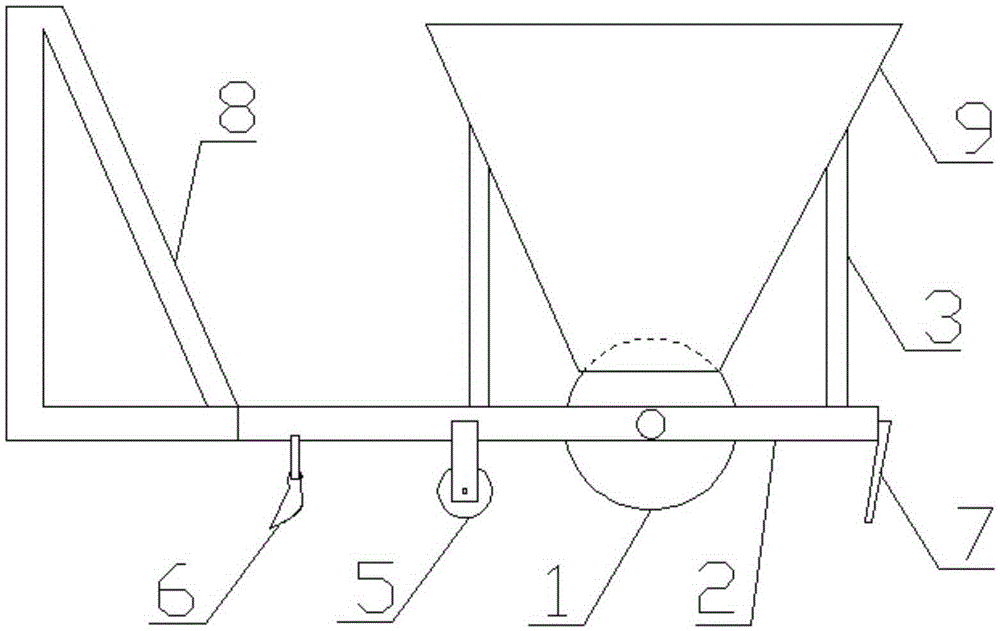

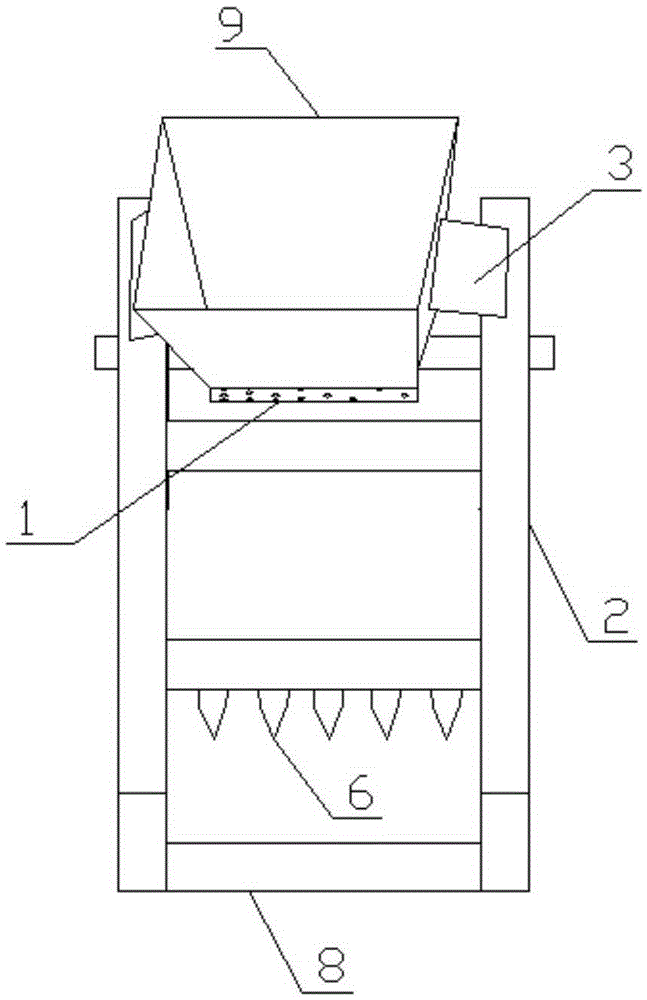

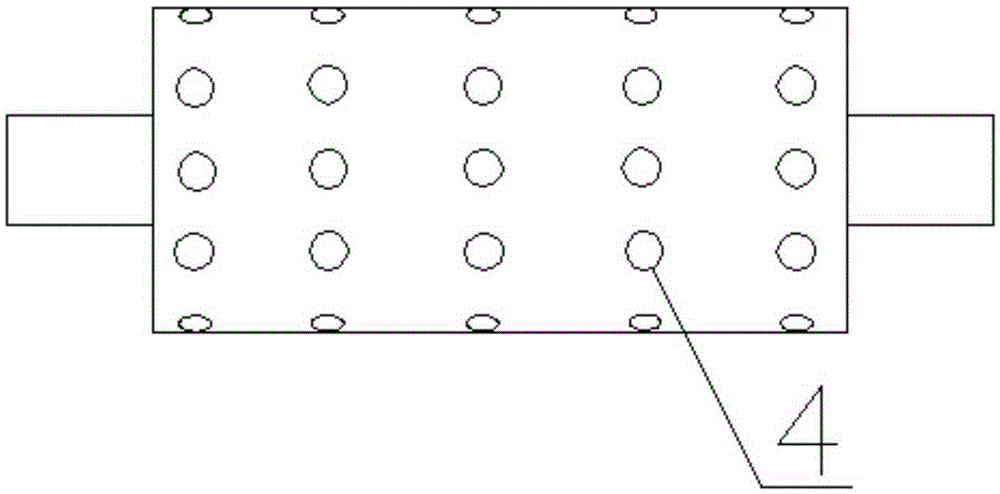

[0021] Such as Figure 1 to Figure 3 As shown, a kind of garlic device includes a hopper 9, a cylindrical material roller 1, the upper and lower ends of the hopper 9 are open, and the material roller 1 is rotatably connected to the base frame 2 through shafts at both ends thereof. The surroundings of the lower end of the hopper 9 are fitted and slidably connected to the upper part of the material roller 1. The hopper 9 is fixedly connected to the base frame 2 through the bracket 3. The circumference of the material roller 1 is provided with multiple rows of arcs along its length direction. shaped groove 4, the row spacing between multiple rows of grooves 4 is 18-25cm, the distance between each row of grooves 4 is 12-20cm, the depth of the groove 4 is 28-50mm, the groove 4. The size of the upper end opening is 20mm-40mm, and the base frame 2 is provided with road wheels 5 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com