Knapsack No-till Wide Format Fertilizer Planter

A knapsack and seeder technology, which is applied to fertilizers and seeding equipment, etc., can solve the problems of ineffective sowing, incomplete sowing, and difficult dismantling, etc., and achieve the effect of facilitating promotion and implementation, good use effect, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

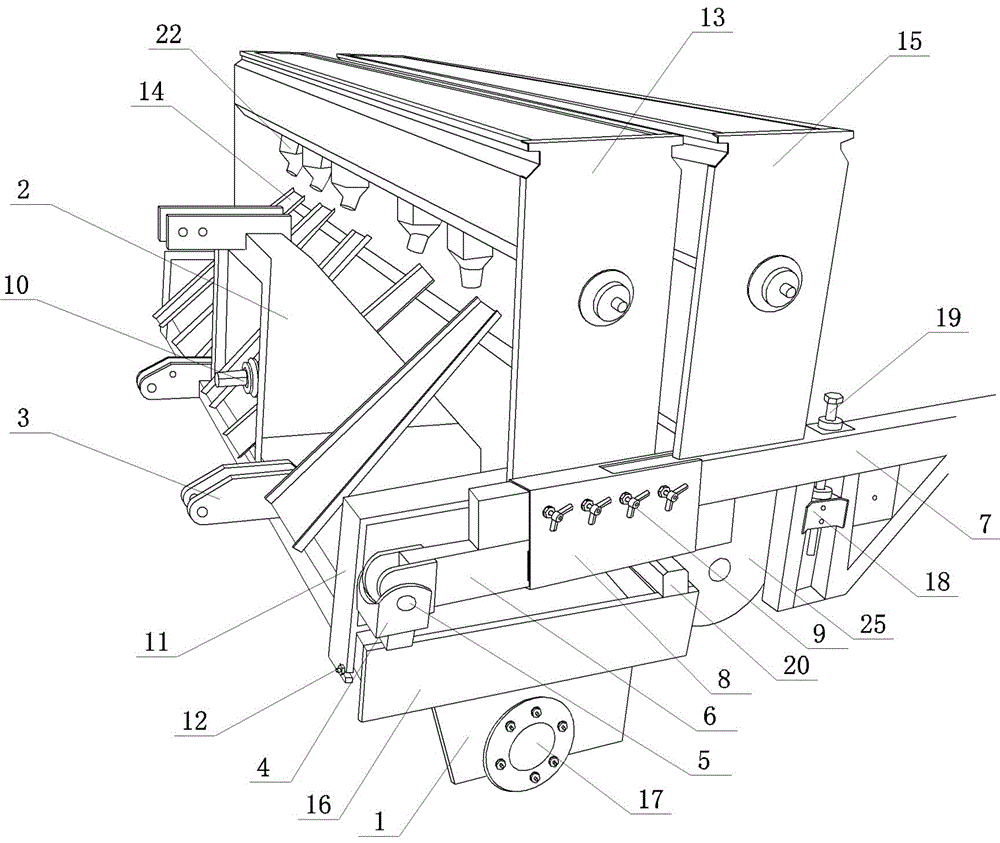

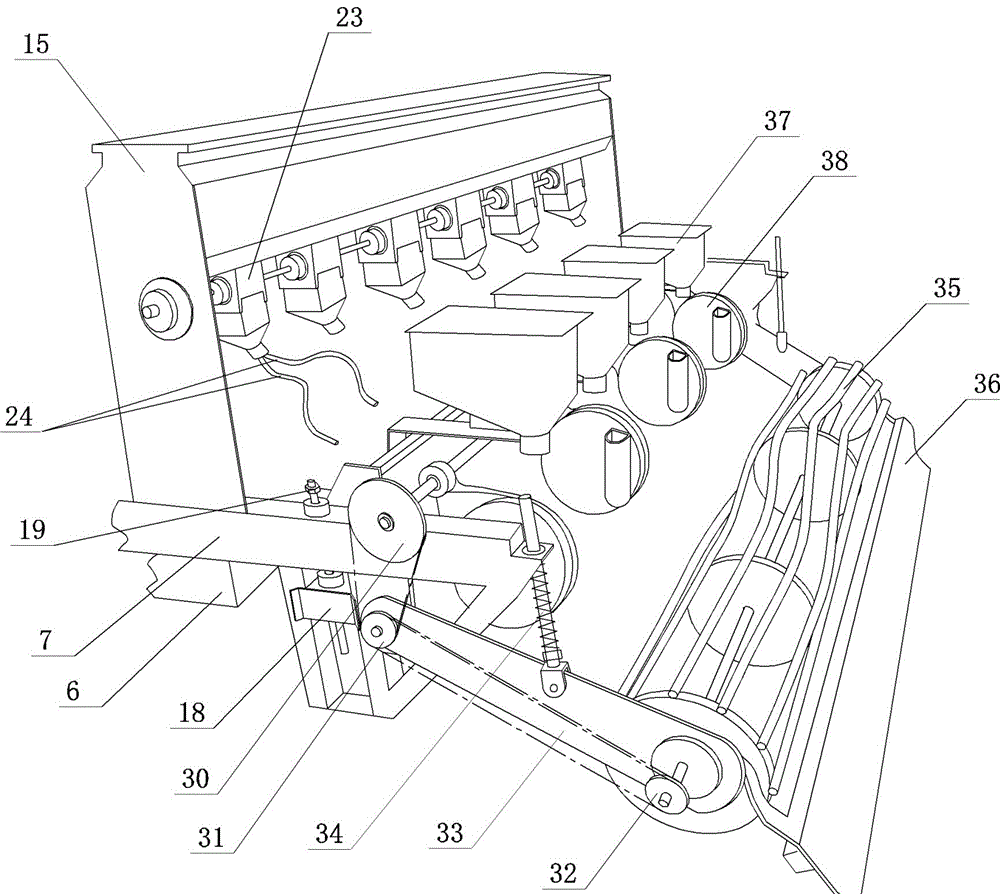

[0016] Example: see figure 1 , Knapsack-type no-till wide-width fertilizing planter includes a frame 1, a traction mechanism and a transmission mechanism. The fertilizing equipment is installed at the front end of the frame 1, and the seeding equipment is installed at the back end of the frame 1.

[0017] Among them, the traction mechanism is installed in the middle of the front end of the frame 1. The traction frame 2 of the traction mechanism is connected with a traction arm 3 or a supporting arm up and down. A gear box is also fixed inside the traction frame 2, and the input shaft of the gear box is connected to the traction machine for transmission, and the output shaft of the gear box is used as a drive shaft and is respectively connected to various running parts through a transmission mechanism.

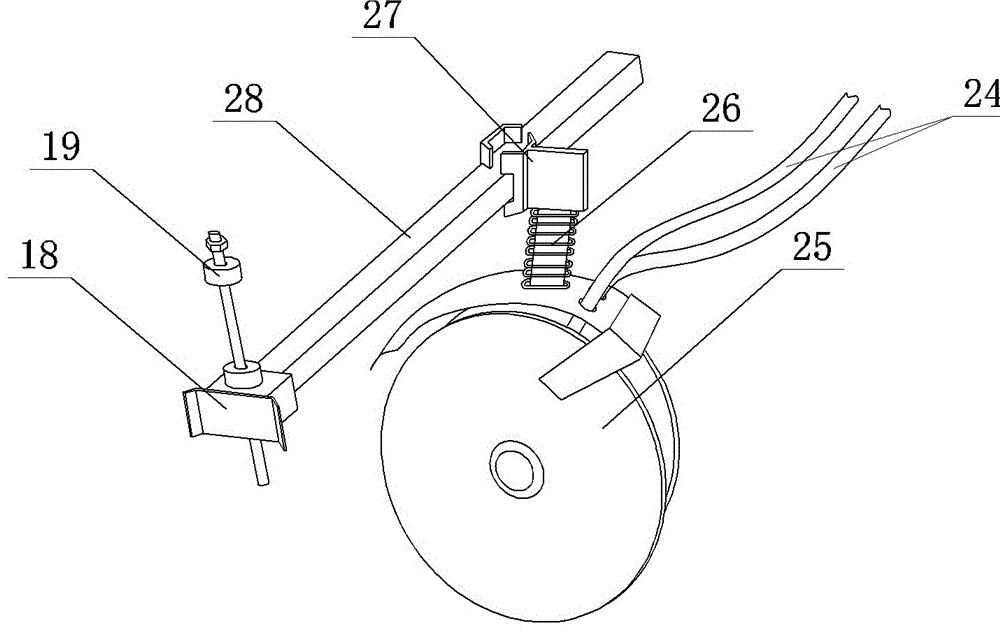

[0018] The two sides of the front end of the frame 1 are respectively provided with shaft sleeves 4, and two swing beams 6 are respectively installed in the corresponding shaft slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com