A tool and replacement method for replacing fan unit body in the field

A replacement method and unit body technology, applied in the field of aero-engines, can solve the problems of rotor stator scraping and inability to replace the working blades of the fan unit body, and achieve the effect of avoiding returning to the factory for repair, ensuring the use rate and saving cycles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

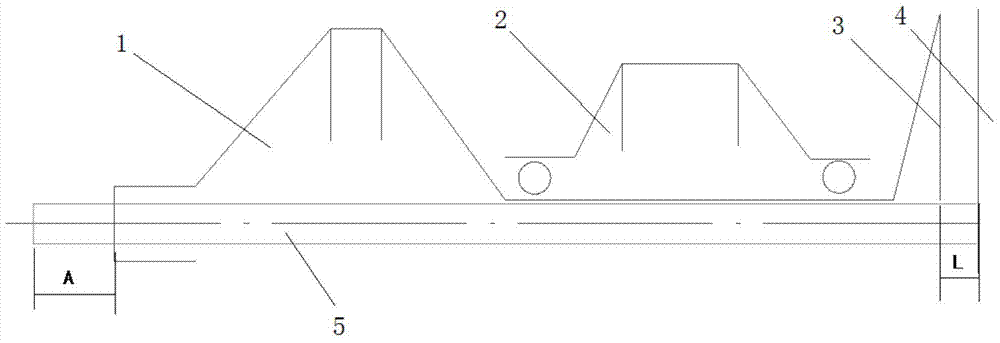

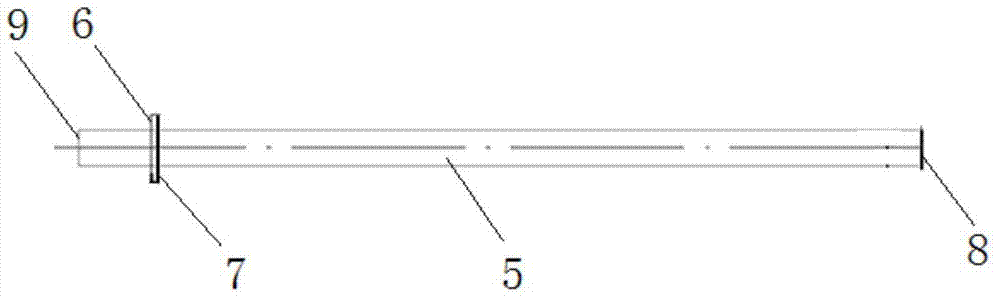

[0024] Example: such as figure 1 , figure 2 As shown, the present invention includes a positioning rod 5 and a baffle plate 6, and the positioning rod 5 is provided with an adjustable baffle plate 6. During use, the positioning rod 5 is placed in the low-pressure rotor 1, the high-pressure rotor 2 and the low-pressure turbine rotor of the engine. , one end of the positioning rod 5 is in contact with the rear fulcrum bearing housing 4, the other end is close to the side of the engine intake cap cover, the adjusting baffle 6 is placed on the end face of the low-pressure rotor shaft, the measuring end face 7 of the measuring baffle 6 is in contact with the end face of the positioning rod 5 The distance A between.

[0025] The baffle plate 6 is connected to the positioning rod 5 through locking screws.

[0026] Or the baffle plate 6 is connected with the positioning rod 5 through a slider chute and fixed by a pin.

[0027] Such as figure 1 , figure 2 As shown, the method fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com