Vibration theory based manifold thermal shield support mounting positioning method

A technology of installation positioning and heat shield, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve theoretical analysis and research, the installation and positioning position of the connecting bracket still stays, and the welding part of the connecting bracket is easy to break, etc. problem, to achieve the effect of solving the problem of location layout, avoiding returning to the factory for repair, and avoiding irrationality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

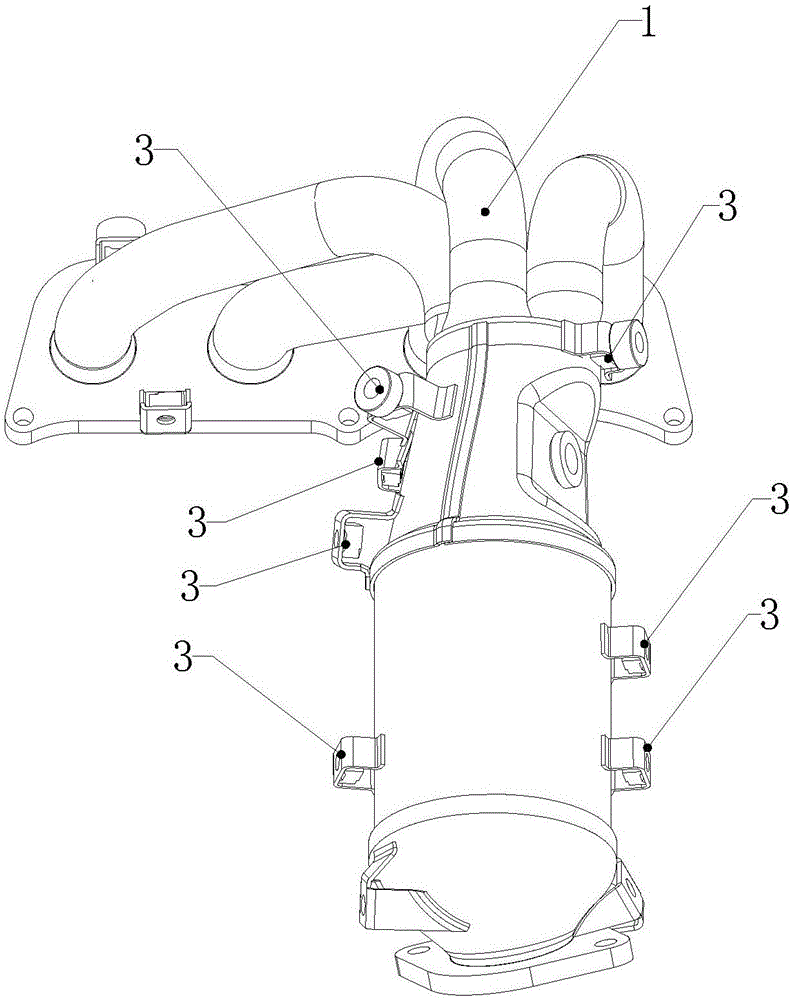

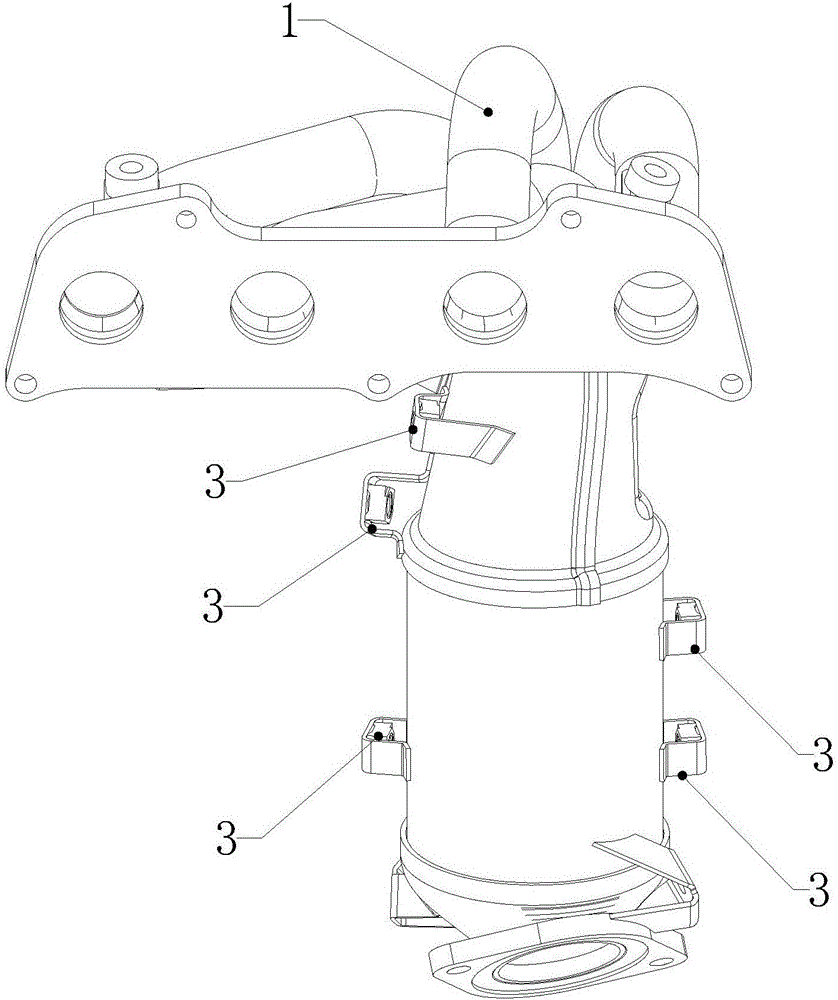

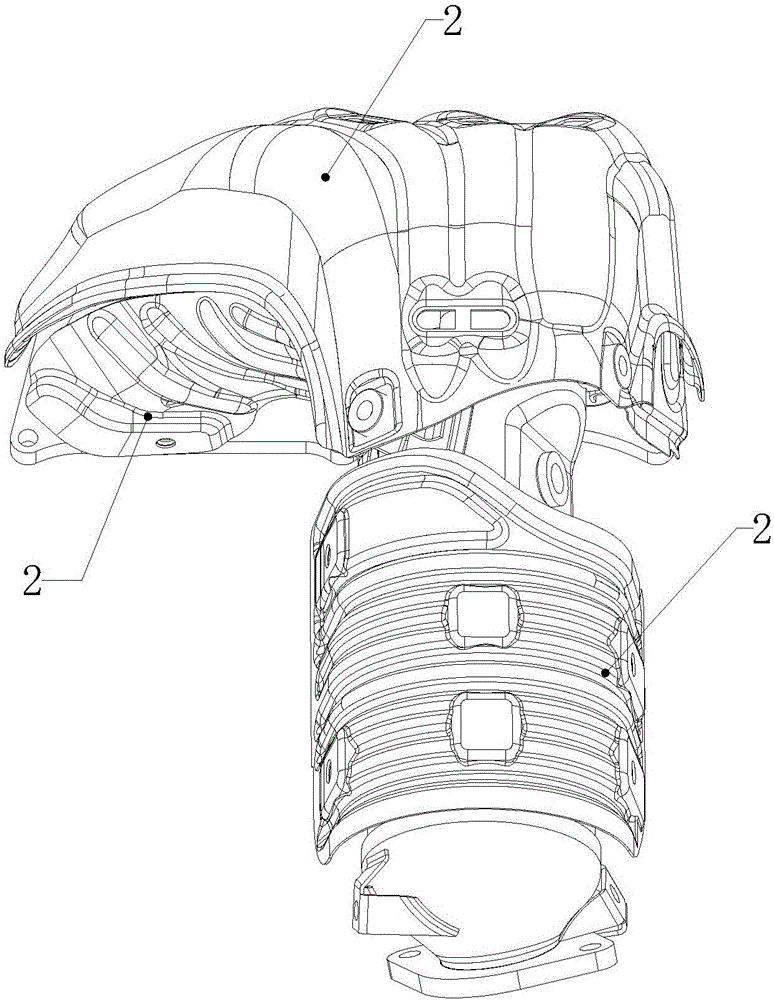

[0023] see Figure 1 to Figure 3 According to a preferred embodiment of the present invention, a method for installing and positioning a manifold heat shield bracket based on vibration theory includes the following steps:

[0024] S1: Arrange multiple collection points on the exhaust manifold 1, conduct modal analysis on the exhaust manifold through the hammering method, and obtain the modal frequency of each mode of the exhaust manifold and the modal frequency The corresponding mode shapes;

[0025] S2: According to the ADDOFD method, calculate the value x corresponding to the characteristic displacement of each acquisition point at each modal frequency r ,which is:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com