LED (light emitting diode) display screen

A technology of LED display screen and LED cabinet, which is applied in the field of display screens, and can solve problems such as difficulty in maintaining consistent dot spacing of LED display screens, inability to achieve seamless splicing of cabinets, and difficulty in exactly the same size, so as to achieve convenient splicing and disassembly Quick, low cost, and the effect of improving the flatness of splicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

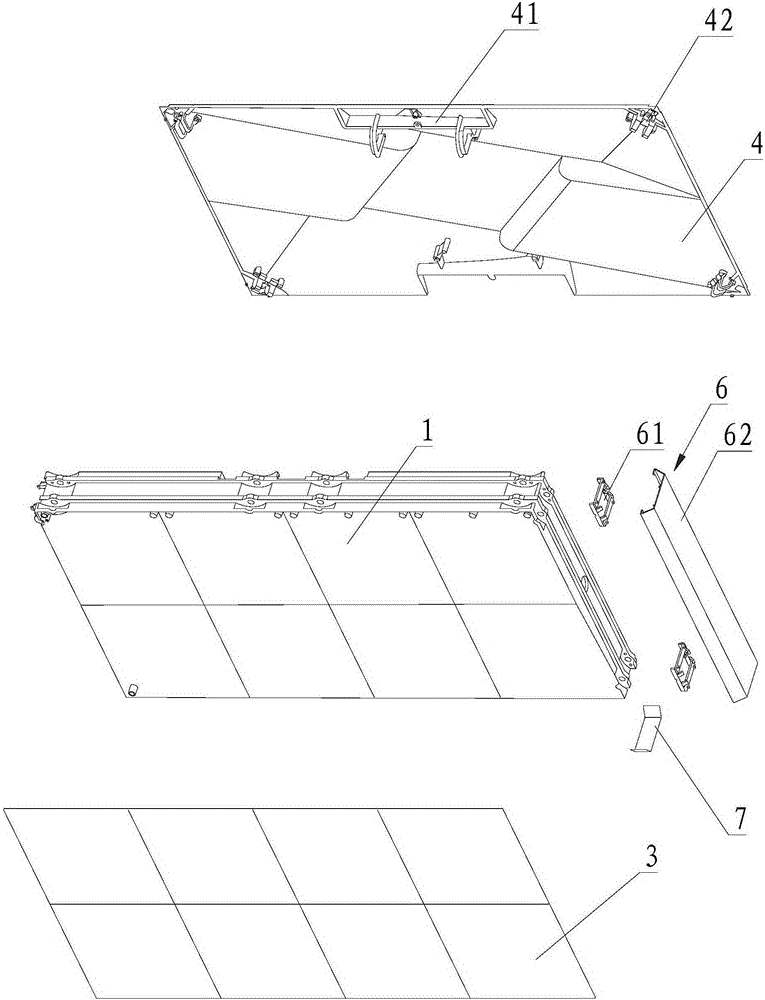

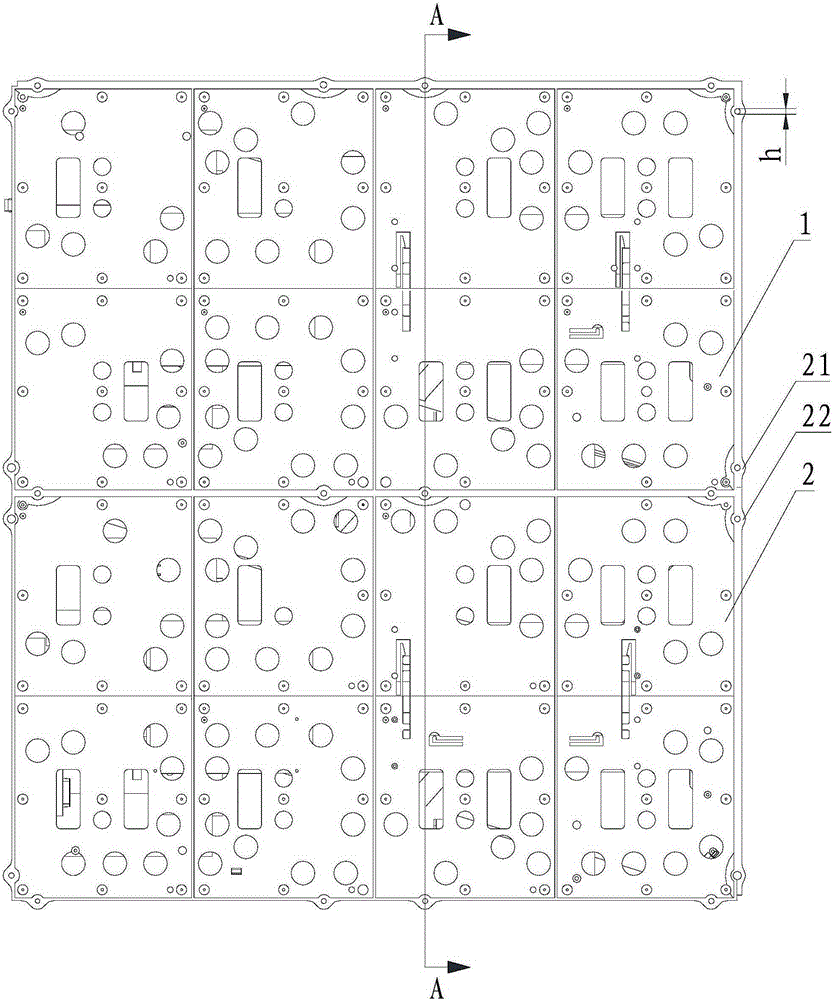

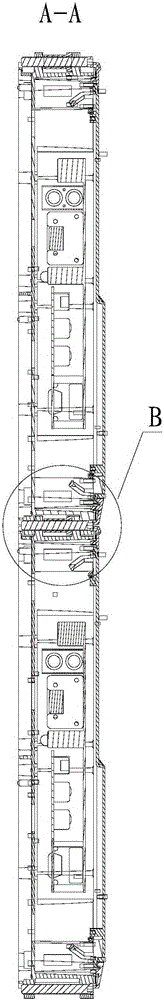

[0037] Please refer to Figure 1 to Figure 5 , The first embodiment of the present invention is:

[0038] An LED display screen, comprising a first LED box body 1, a second LED box body 2, an LED display module 3, a back cover 4, and a fastener 5. On the first LED box body 1 and the second LED box body 2, The LED display modules 3 are respectively provided, the first LED box 1 and the second LED box 2 are respectively provided with a back cover 4 on one side, and the first LED box 1 and the second LED box 2 are arranged adjacently.

[0039] More than two first grooves 11 are provided on the end surface of the first LED box 1, two first positioning protrusions 12 are provided in the first groove 11, and two first positioning protrusions 12 are provided on the end surface of the second LED box 2. There are more than one second groove 21. The two ends of the second groove 21 are respectively provided with second positioning protrusions 22. The number of the first groove 11 and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com