Splicing platform

A platform and connecting block technology, applied in workbenches, manufacturing tools, etc., can solve problems such as poor structural stability, poor splicing flatness, and splicing gaps, and achieve the effects of convenient assembly and disassembly, elimination of splicing gaps, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

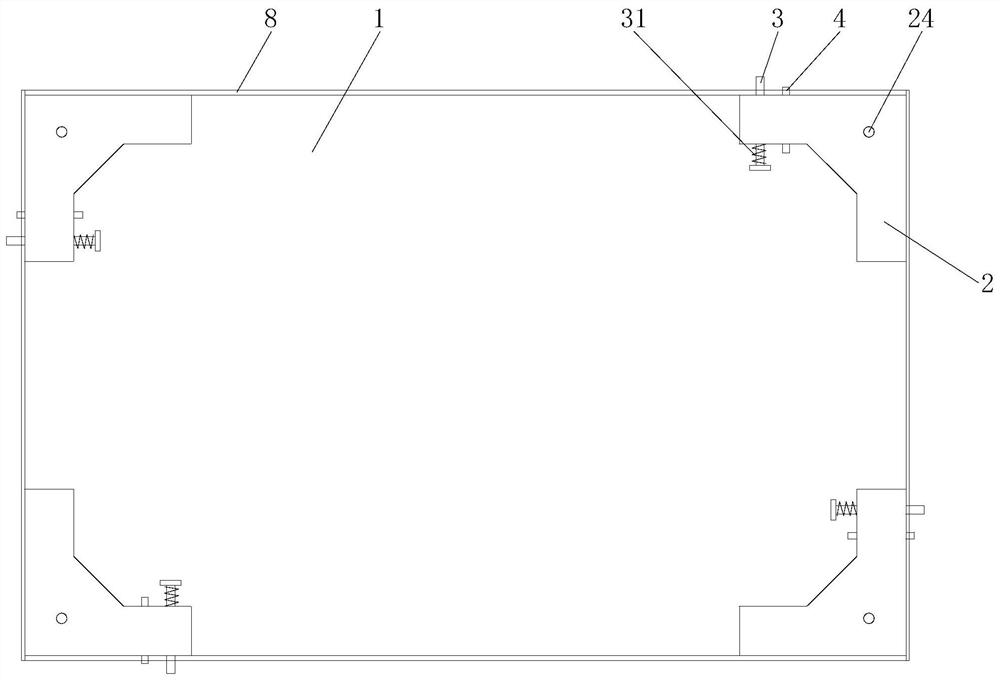

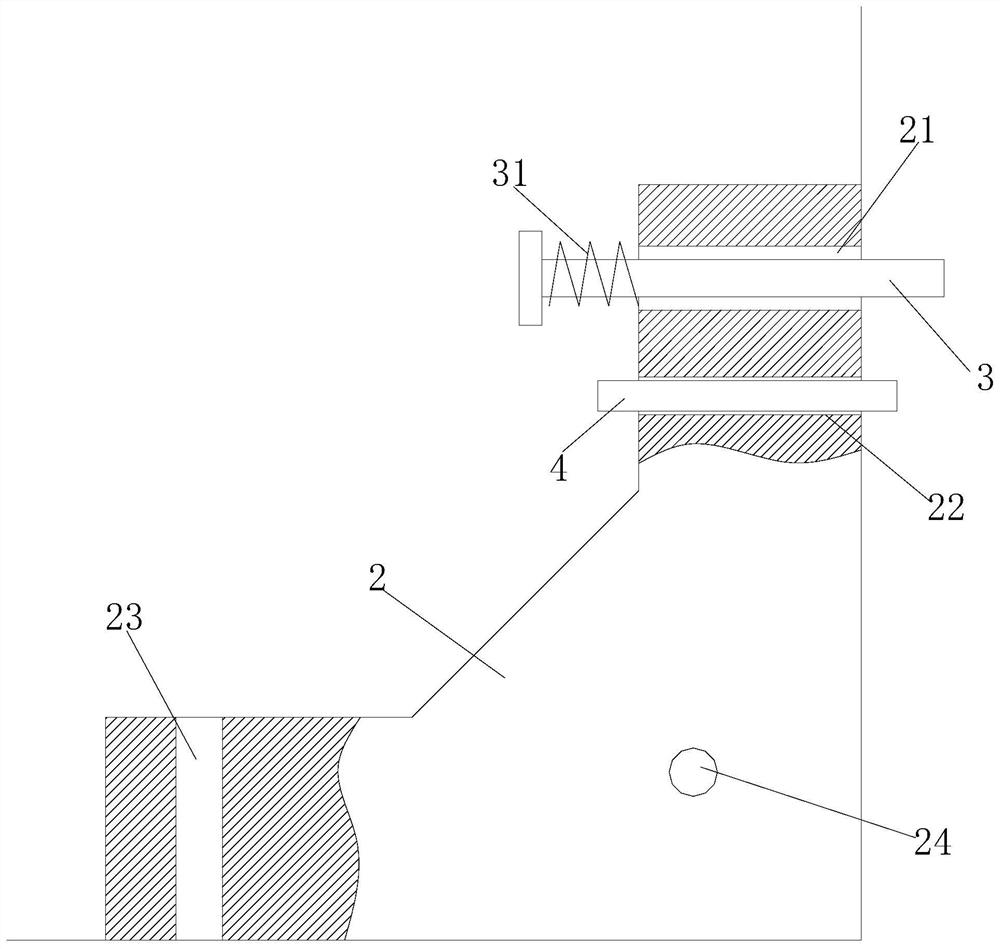

[0025] Such as Figure 1 to Figure 4 As shown, a splicing platform mainly includes a board surface 1, the board surface 1 is rectangular, the four corners of the board surface are respectively provided with connecting blocks 2, and the described connecting blocks 2 are roughly L-shaped, Along the two side edges of the corner, the connecting block 2 is provided with a first through hole 21 and a first screw hole 22 axially along the plane direction of the plate surface 1, and the first through hole and the first screw hole The axes of the holes are parallel to each other. Specifically, the first through hole and the first screw hole are located on one side of the L-shaped connecting block 2, and the axes of the first through hole and the first screw hole are perpendicular to the rectangular plate where they are located. The edge of the surface 1, the first through hole is penetrated with a first tension bolt 3 with a diameter smaller than the first through hole, and the connect...

Embodiment 2

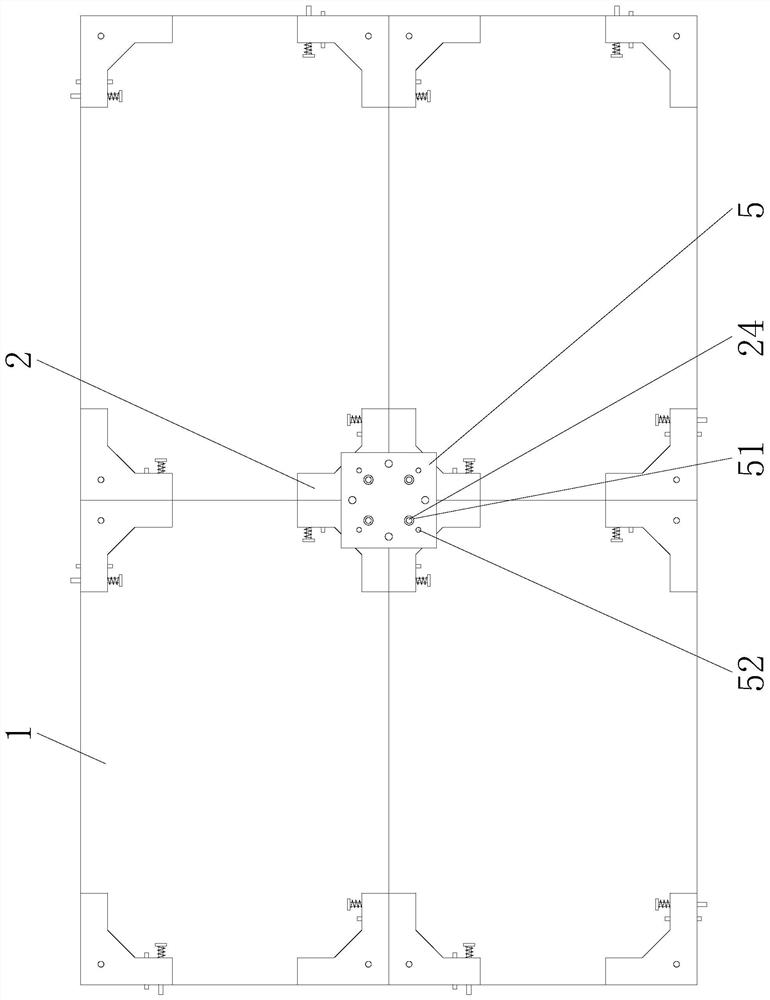

[0032] Such as Figure 5 As shown, the difference from Embodiment 1 is that the board surface 1 is in the shape of a regular hexagon, and three board surfaces 1 are joined together at a splicing point, and the six corners of the hexagonal board surface 1 The axial directions of the first through hole and the first screw hole on the connecting block 2 are 60° in the clockwise direction, which can also ensure the stability of the splicing structure, and flexibly adjust the splicing flatness, eliminate the splicing gap, and ensure the use reliability and security.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com