Lining cloth blanketing, splicing and tailing machine

A technology of spreading and interlining, which is applied in the cutting of textile materials, textiles and papermaking, laminating devices, etc., can solve the problems of wasting manpower, low work efficiency, poor splicing flatness, etc., and achieves convenient operation and improves splicing flatness. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

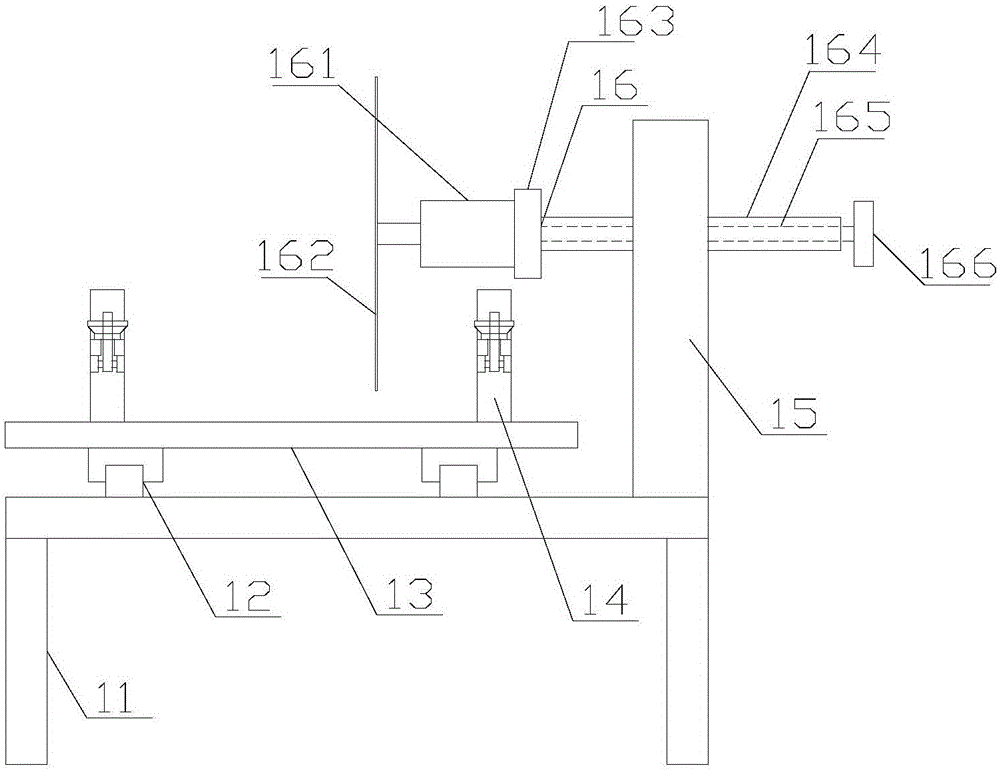

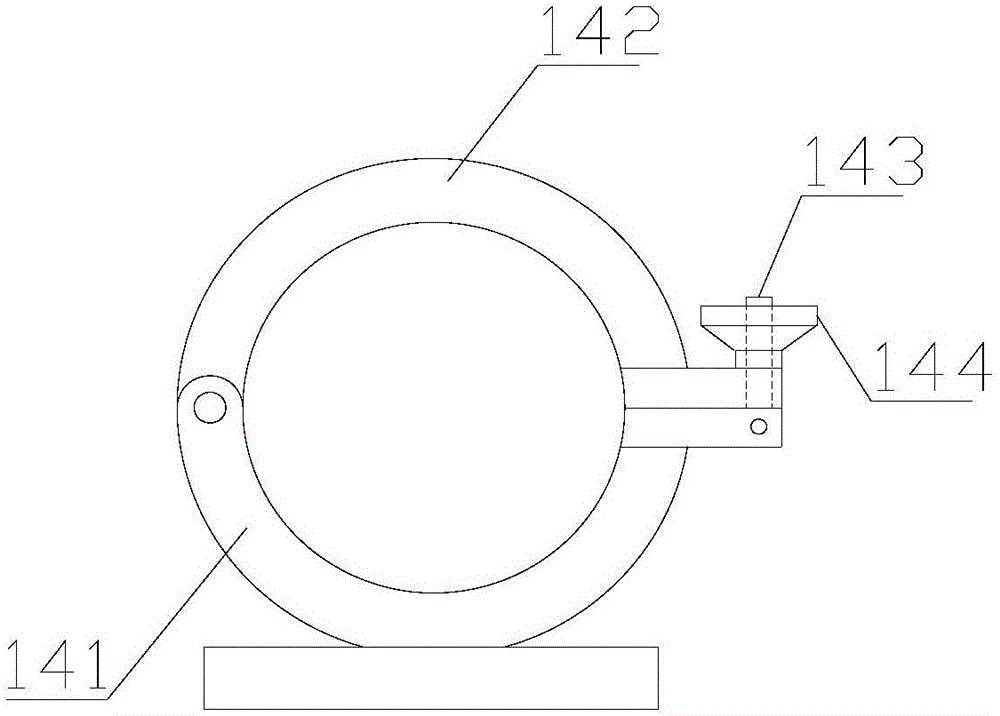

[0021] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , an interlining spreading and cutting machine of the present invention comprises a cutting device 1, an unwinding device 2 and a bonding device 3, and the cutting device 1, the unwinding device 2 and the bonding device 3 are sequentially arranged from front to back, so The cutting device 1 includes a support 11, a slideway 12, a base 13, a fixed seat 14, a support 15 and a cutting mechanism 16, the support 11 is provided with a slideway 12 and a support 15, and the slideway 12 is equipped with Base 13, the front and rear parts of the base 13 are provided with fixed seats 14, the support 15 is provided with a cutting mechanism 16, and the bonding device 3 includes a frame body 31, a cloth guide frame 32, a pressing Mechanism 33 and glue spraying mechanism 34, the front end and the rear end of described frame body 31 are respectively provided with guide frame 32 and pressing mechanism 33,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com