System and method for recognizing motion state of twisting type roller winding and unwinding steel wire rope

A motion state and identification system technology, which is applied in transportation, packaging, elevators, etc., can solve the problems of inability to identify the motion state of wire ropes, and achieve the effects of visualization, low-cost signal acquisition, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

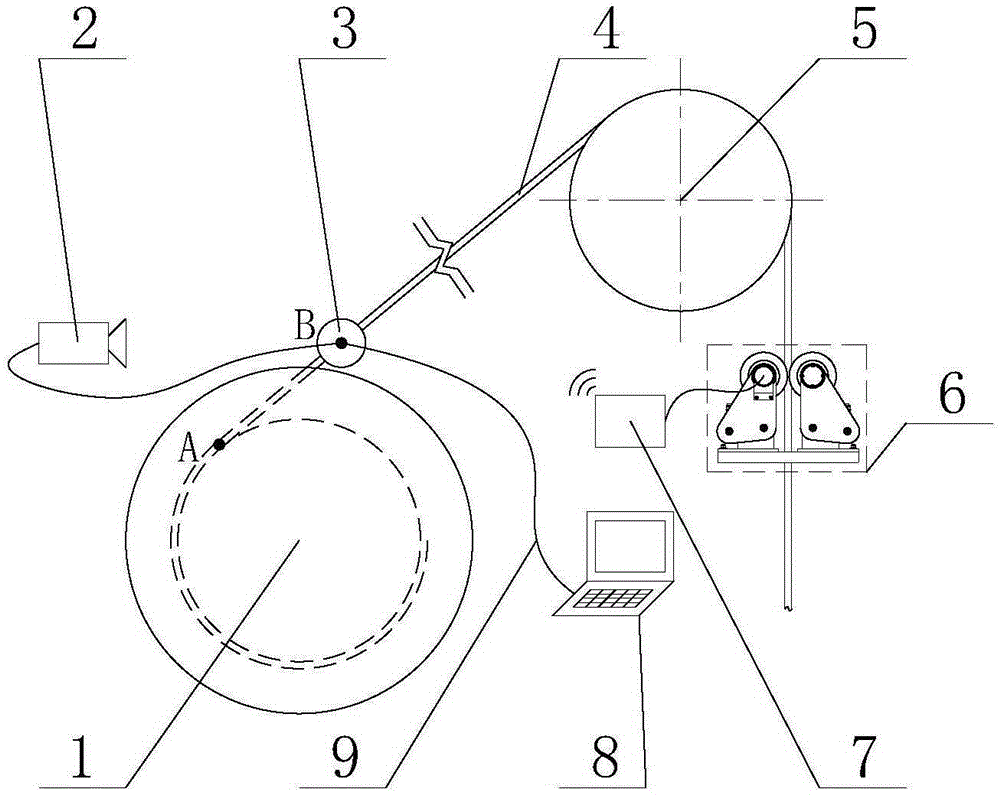

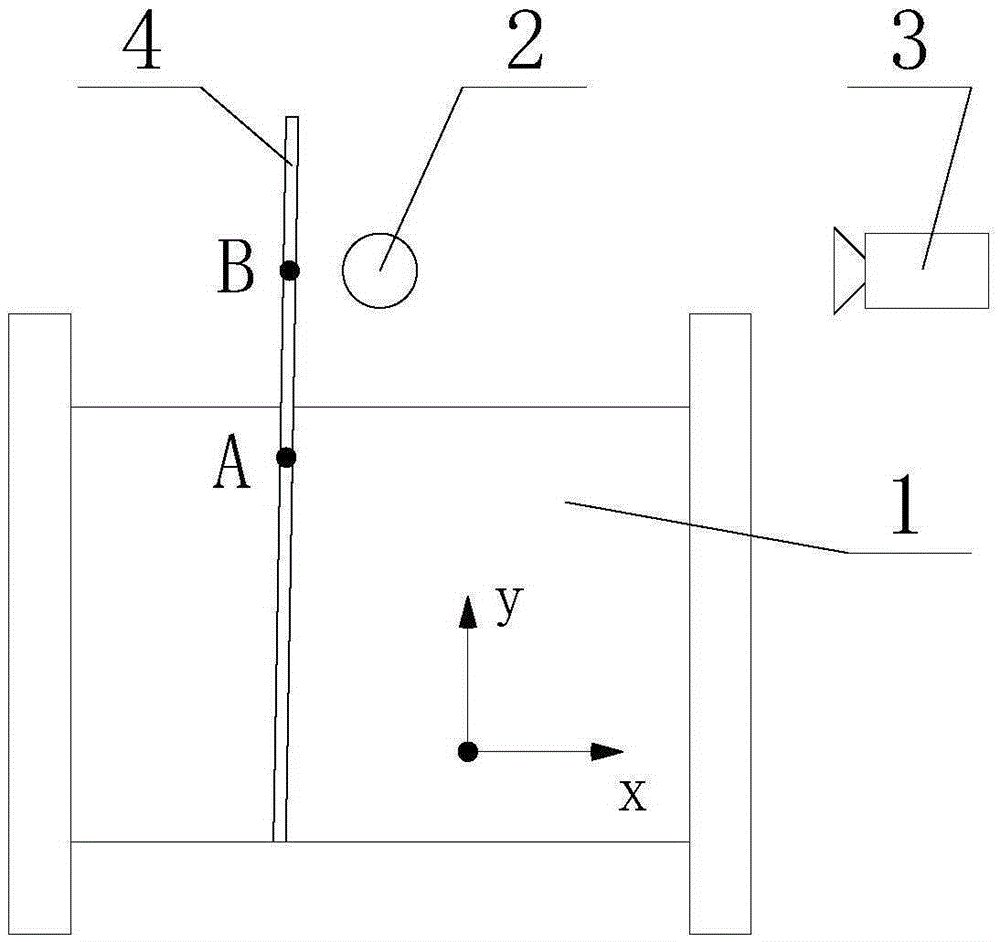

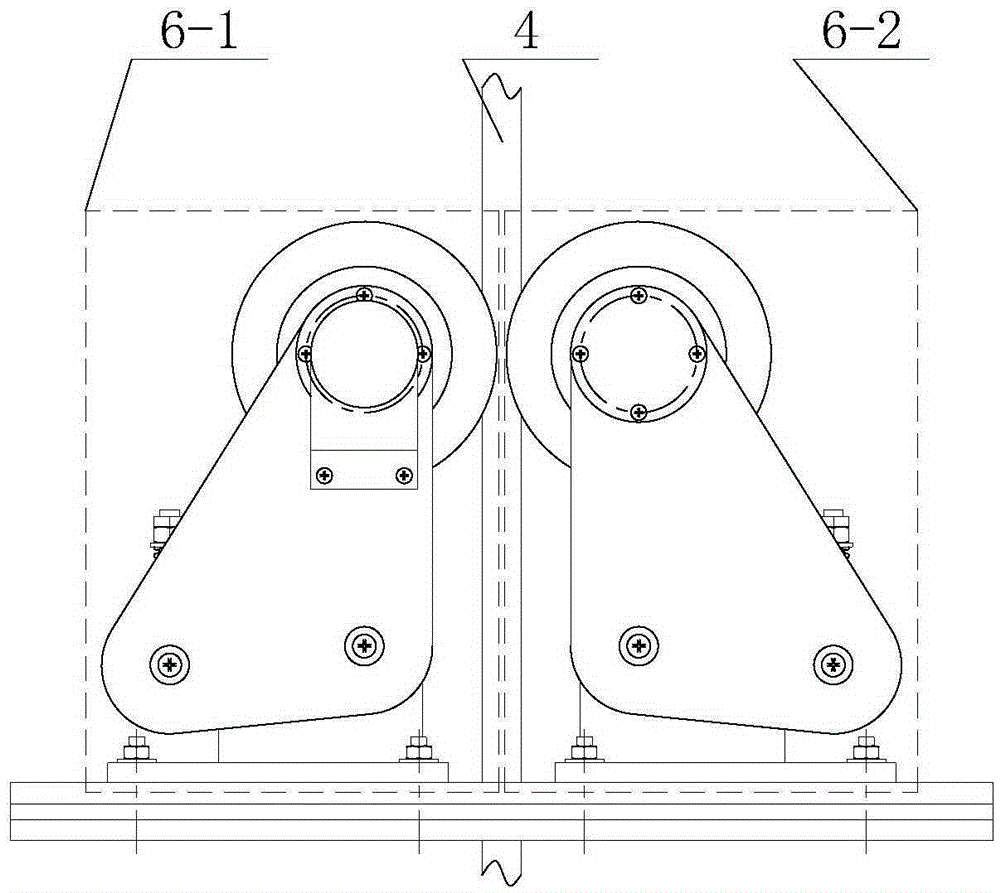

[0033] Such as Figure 1-2 As shown, the winding type drum unwinding wire rope motion state recognition system of the present invention includes an industrial camera 1 installed on the rear and upper side of the drum 1 perpendicular to the drum axis and an industrial camera 2 3 installed on the right side of the drum 1 parallel to the drum axis. Due to the structure of the drum, the industrial camera 23 cannot capture the global longitudinal motion state of the ideal steel wire rope measuring point A at the tangent between the steel wire rope 4 and the drum 1. The distance between the actual wire rope measuring point B on the edge is extremely small compared with the distance between the drum 1 and the sky wheel, and the motion state of the actual wire rope measuring point B is basically the same as the motion state of the ideal wire rope measuring point A,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com