A comprehensive effect evaluation method for thermobaric explosives in semi-closed tunnel explosions

A technology of thermobaric explosives and evaluation methods, which can be used in measurement devices, instruments, scientific instruments, etc., and can solve problems such as incompleteness and inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] According to the above method, the inventor evaluated the comprehensive explosion effect of the thermobaric explosive of formula 1 in a semi-closed tunnel environment.

[0087] The test explosion tunnel has a width of 2m, a height of 2.5m, a round arch at the top, a tunnel length of 80m, and a blast carrying capacity of less than 5kgTNT equivalent. Evaluation of thermobaric explosives, TNT is cylindrical, with a mass of 2kg and a density of 1.85g / cm 3 .

[0088] Table 1 is the equipment and status used in the test, and Table 2 to Table 5 are the test measurement results.

[0089] Table 1 List of test equipment equipment status

[0090]

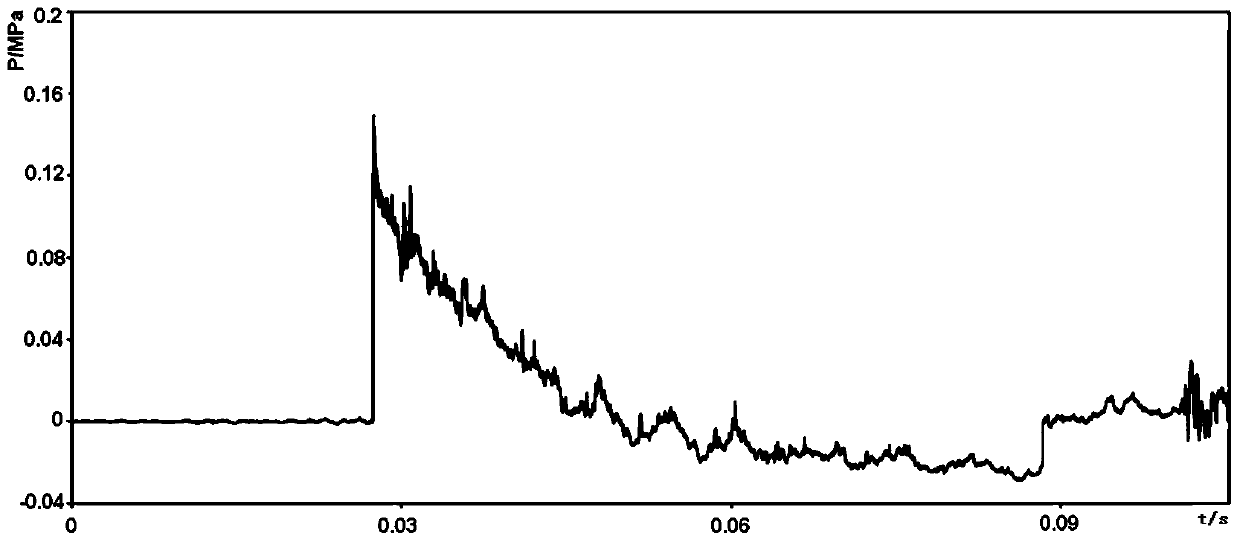

[0091] Table 2 Measurement results of shock wave effect characterization parameters

[0092]

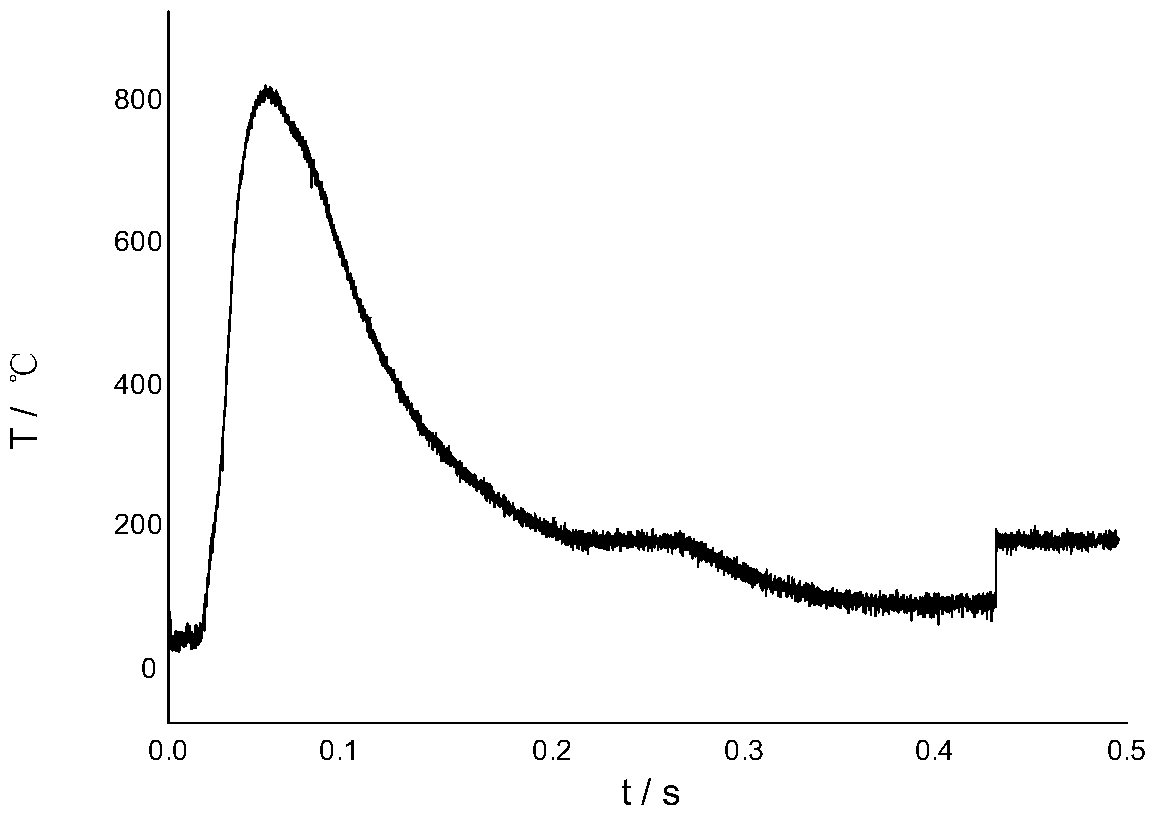

[0093] Table 3 Measurement results of thermal effect characterization parameters

[0094]

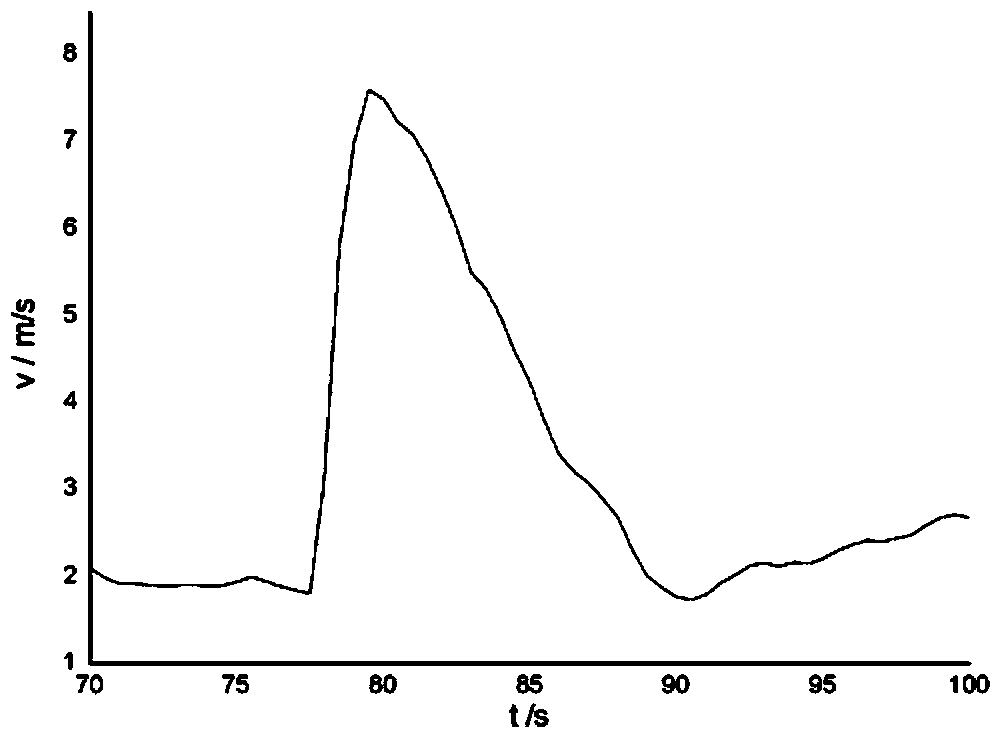

[0095] Table 4 Measurement results of wind pressure effect characterization parameters

[0096]

[0097] Table 5 Measurement results o...

Embodiment 2

[0106] According to the above method, the inventor evaluated the combined explosion effect of formula 2 thermobaric explosive in a semi-closed tunnel environment.

[0107] The test blast tunnel is the same as Example 1. The evaluation formula 2 is a cylindrical explosive with a mass of 2kg and a density of 1.88g / cm 3 .

[0108] The equipment used in the test is the same as in Example 1, and Table 6-Table 9 are the test measurement results.

[0109] Table 6 Measurement results of shock wave effect characterization parameters

[0110]

[0111] Table 7 Measurement results of thermal effect characterization parameters

[0112]

[0113] Table 8 Measurement results of wind pressure effect characterization parameters

[0114]

[0115] Table 9 suffocation effect characteristic parameter measurement results

[0116]

[0117] According to the data in Table 6 and the empirical formula of shock wave pressure peak and impulse, the TNT equivalent of the shock wave overpress...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com