Automatic cooling fireproof steel structure

An automatic cooling and steel structure technology, applied in the direction of fire protection, building components, etc., can solve the problems of steel structure danger, poor fire resistance, temperature rise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

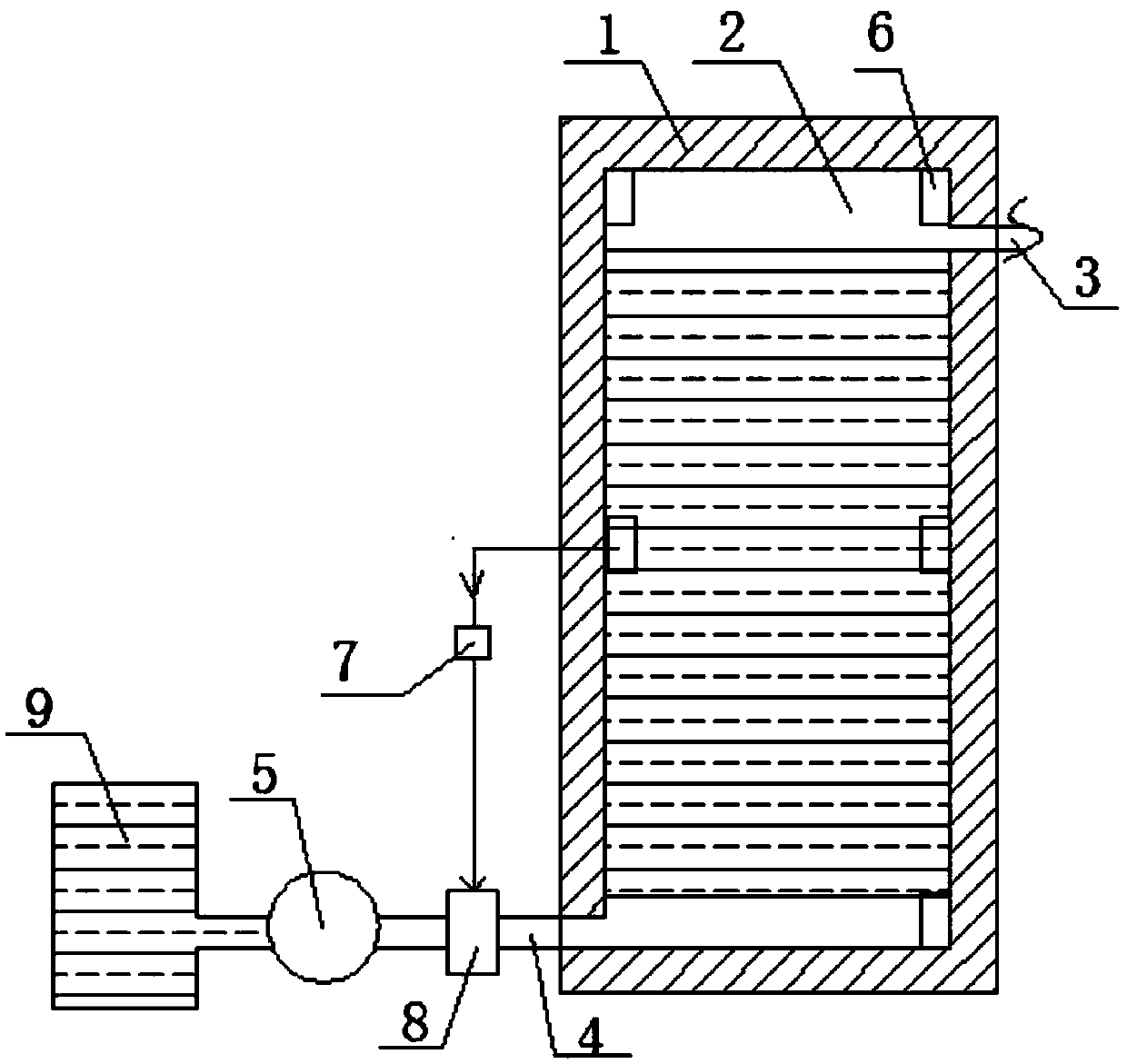

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] Such as figure 1 As shown, the automatic cooling fireproof steel structure includes a steel structure body 1, the body 1 has an inner cavity 2, the upper part of the inner cavity 2 is provided with an exhaust pipe 3, and the lower part is provided with a water inlet pipe 4, and the water inlet pipe 4 is connected through a water pump 5 The water source 9 is also provided with a temperature sensor 6 in the inner cavity 2, the end of the temperature sensor 6 is connected to the signal input terminal of PLC7, and the signal output terminal of PLC7 is connected to the shut-off valve 8 arranged between the water pump 5 and the inner cavity 2.

[0013] The temperature sensors 6 are arranged in the corners and the middle of the inner cavity 2 , such an arrangement can basically achieve balanced temperature measurement and ensure the accuracy of information sent to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com