Layered lifting without avoidance dense three-dimensional garage

A three-dimensional garage without avoidance technology, which is applied in the direction of buildings, building types, buildings, etc. where cars are parked. It can solve the problem that only one car can be parked or picked up at a time, which is not very convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

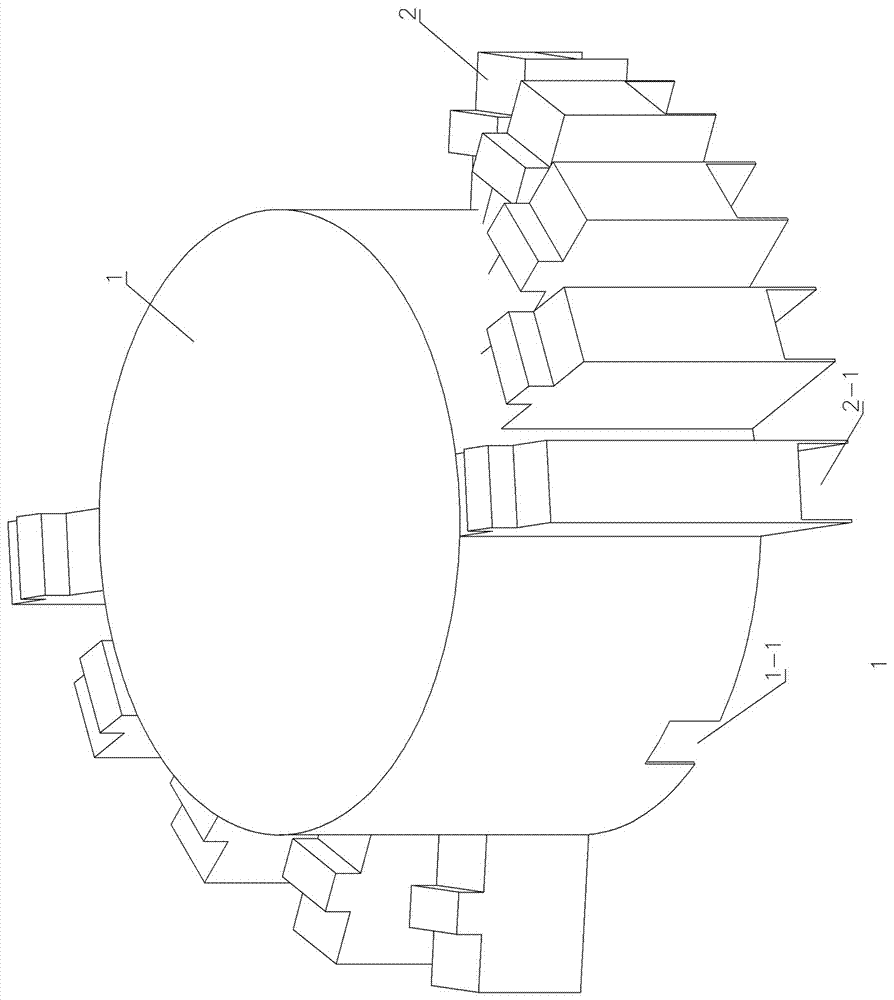

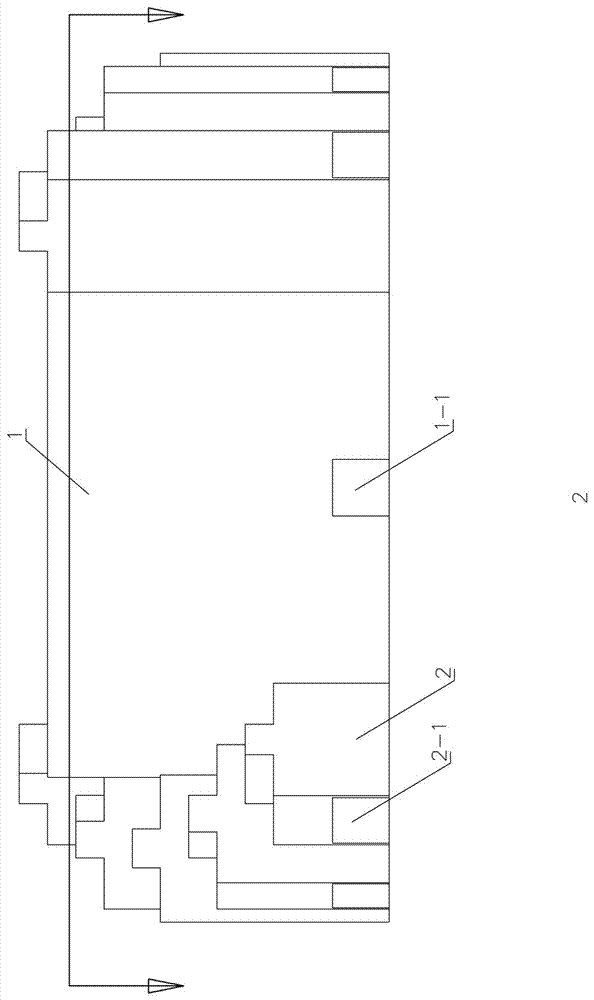

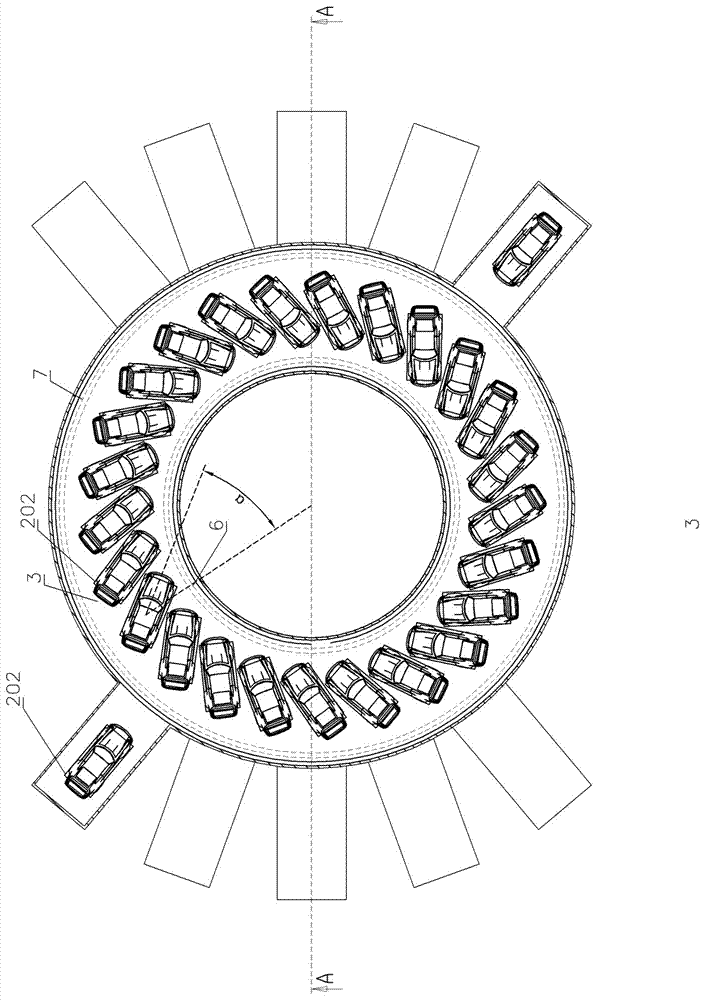

[0031] Embodiment one: see Figure 1-9 , in the figure, a layered lifting and no avoidance dense three-dimensional garage, including the inner wall and the outer wall of the ring garage body, in the garage body is provided with upper and lower N layers of ring-shaped garage floors to divide the garage into N+1 layers, N≥ 2. The garage floor includes a fixed chassis fixedly connected to the two side walls of the garage, a circular guide rail mounted on the fixed chassis, and a cyclically rotatable garage floor arranged on the guide rail. The garage floor is a circular Ring-shaped integrated structure; the bottom of the garage can be rotated under the drive of the drive device, so as to facilitate the adjustment of a suitable parking space or the storage of vehicles near the elevator entrance when the elevator goes up and down, saving waiting time and improving the efficiency of car access.

[0032] At least N sets of lifting devices are provided on the outside of the outer wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com