Gauge stand for repeated positioning detection

A technology of repeated positioning and table seat, applied in the direction of measuring devices, instruments, etc., can solve the problems of no gear repeated positioning detection tooling and table seat, very high requirements for consistent accuracy, and reduced service life of parts, so as to avoid loss of accuracy, The effect of precise consistency and high repeat positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

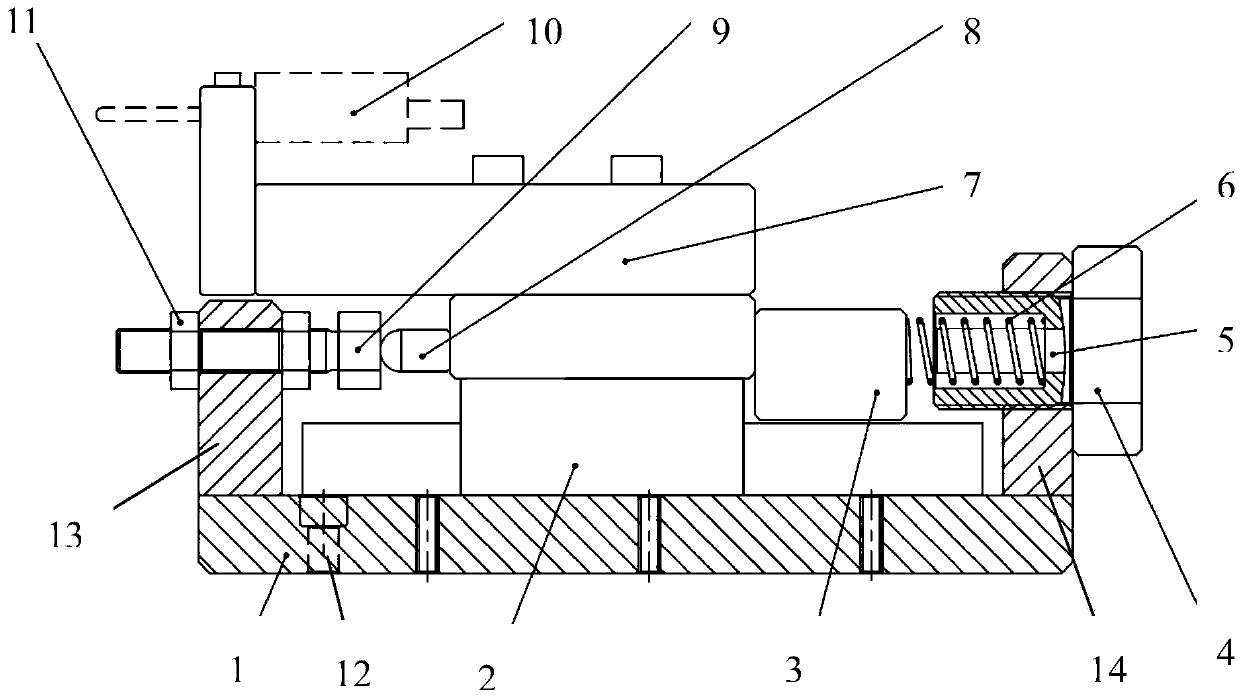

[0008] A table base for repeated positioning detection, including a base 1, a front side wall 13, a rear side wall 14, a linear guide rail 2, a spacer 3, a pre-tightening nut 4, a spring positioning pin 5, a pre-tightening spring 6, and a thousand-point Table seat 7, striker 8, adjusting bolt 9, dial indicator 10, lock nut 11, base 1 is connected with two vertical front side walls 13, rear side wall 14, there are 4-6 bolt holes 12 on the base 1, The linear guide rail 2 is located above the base 1, and is connected and fixed to the base 1 through the bolt hole 12. The spring positioning pin 5 is located on the rear side wall 14, the pre-tightening spring 6 is set on the spring positioning pin 5, and the pre-tightening nut 4 is connected to the spring positioning pin 5. connected, the dial indicator seat 7 is located above the linear guide rail 2 and connected with the linear guide rail 2, the adjusting bolt 9 is located on the front side wall 13, the lock nut 11 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com