A Modular Multilevel Converter Voltage Equalization Control Method

A modular multi-level, voltage equalization control technology, applied in the direction of converting AC power input to DC power output, electrical components, output power conversion devices, etc., can solve problems such as consumption and multiple control times, and reduce data communication. Quantity, improve engineering efficiency, reduce the effect of time occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

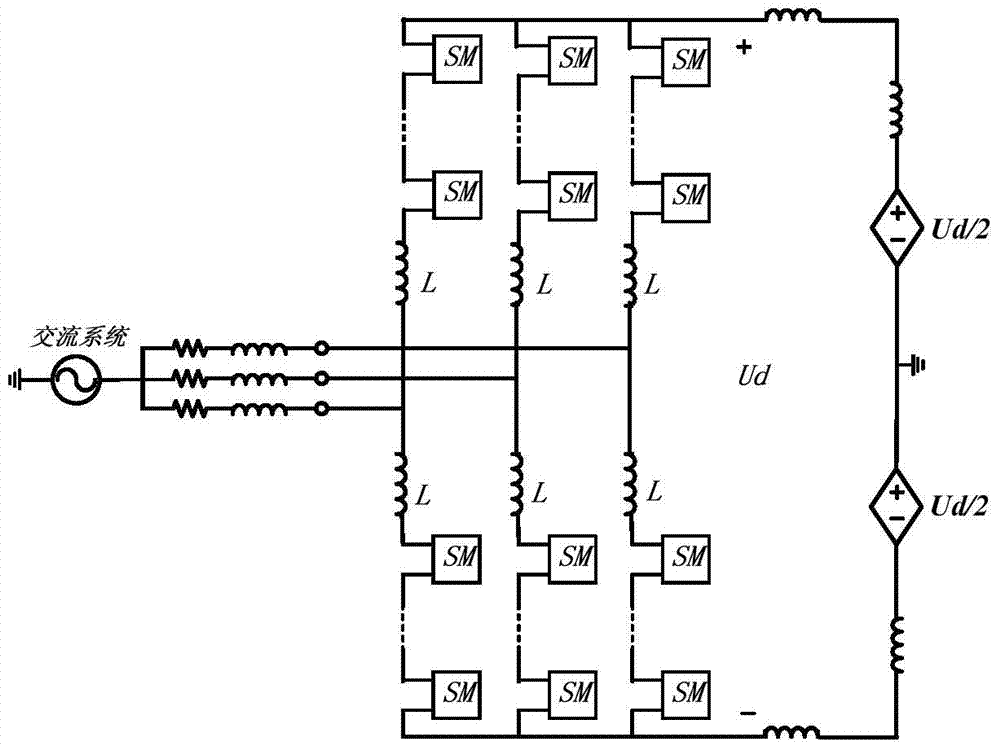

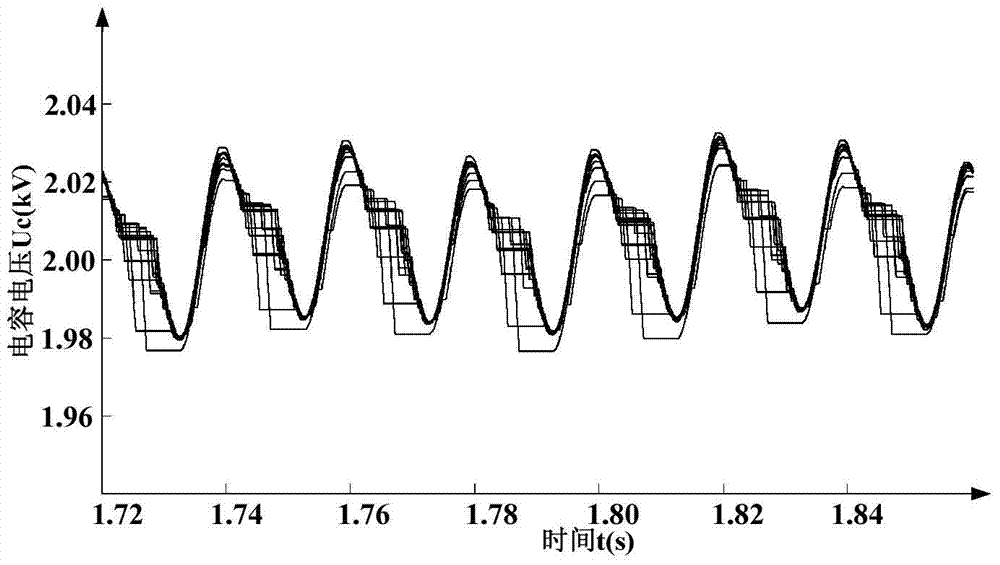

[0025] The present invention proposes a voltage equalization control method for a modularized multilevel converter. The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

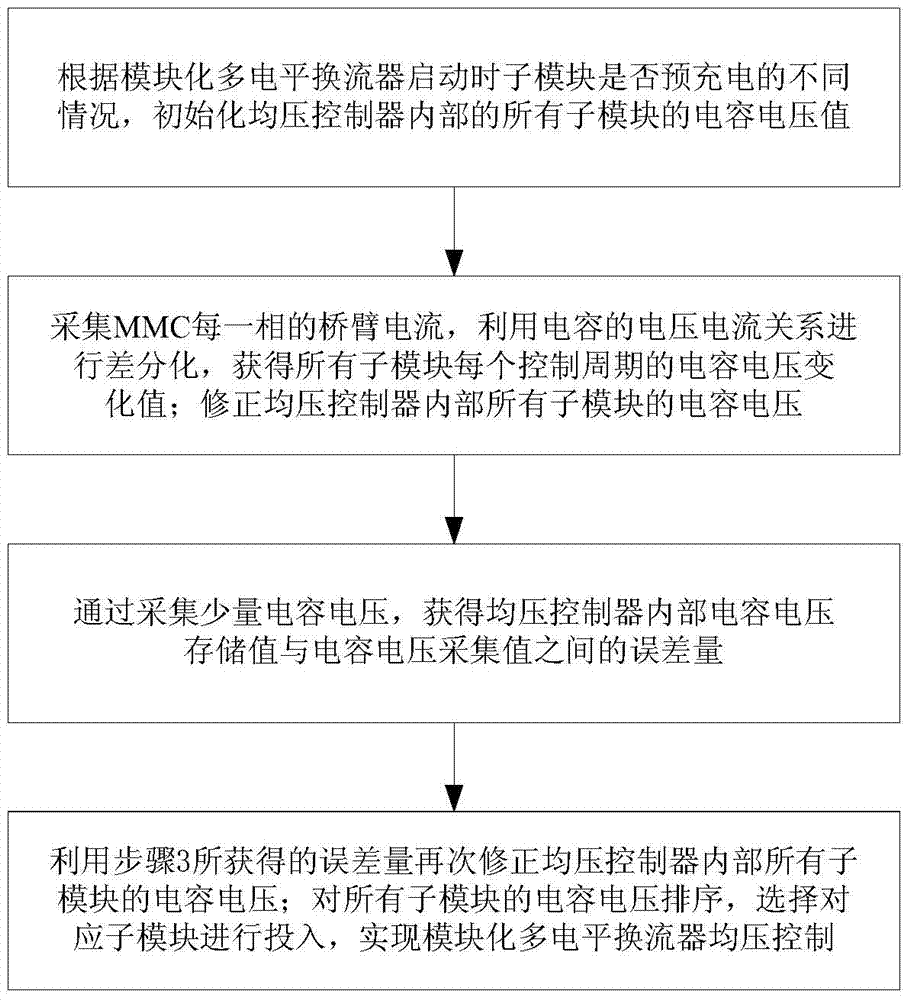

[0026] figure 1 Shown is a flow chart of a voltage equalization control method for a modular multilevel converter, including the following steps:

[0027] 1) According to the different conditions of whether the sub-modules are pre-charged when the modular multi-level converter is started, initialize the capacitor voltage values of all sub-modules inside the voltage equalization controller; when the sub-modules are not charged, The capacitor voltages of all sub-modules are initialized to 0; when the sub-modules have been precharged to the rated value, the capacitor voltages of all the sub-modules inside the voltage equalizing controller are initialized to the rated value U cref ;

[0028] 2) Collect the bridge arm current of each ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com