Forming part manufacturing method and forming machine

A molding machine, molding technology, applied in the field of molding manufacturing and molding machines, to prevent the effect of preventing unacceptable input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

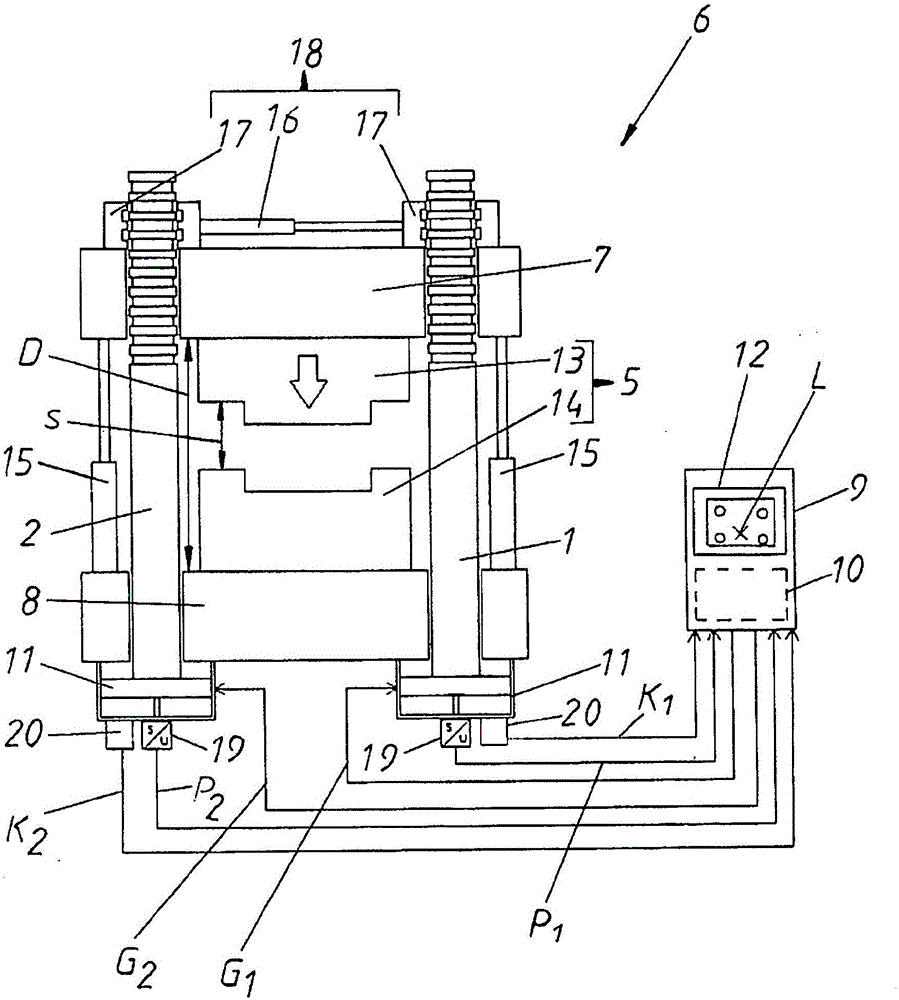

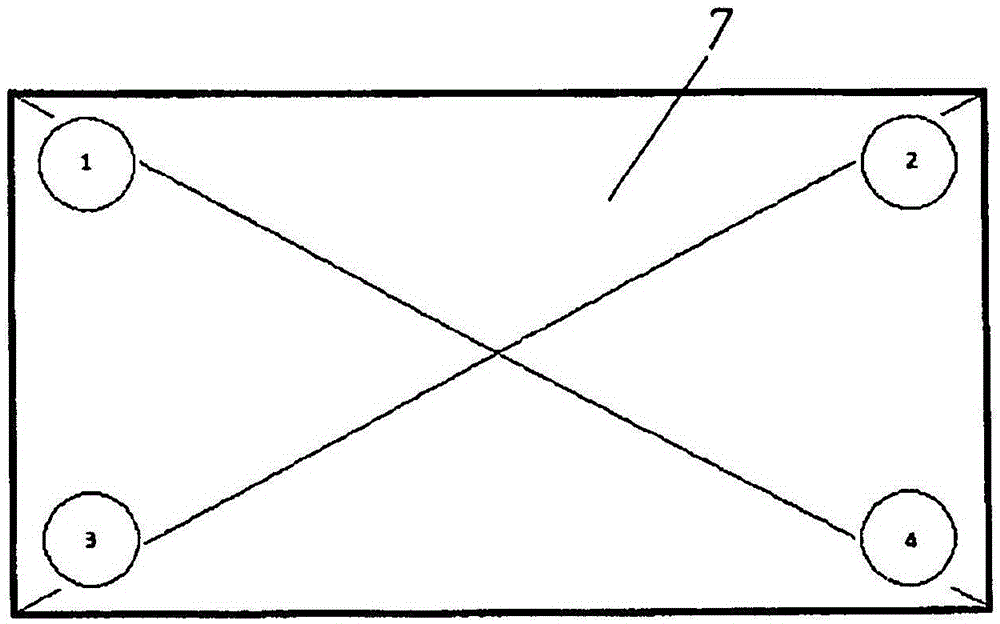

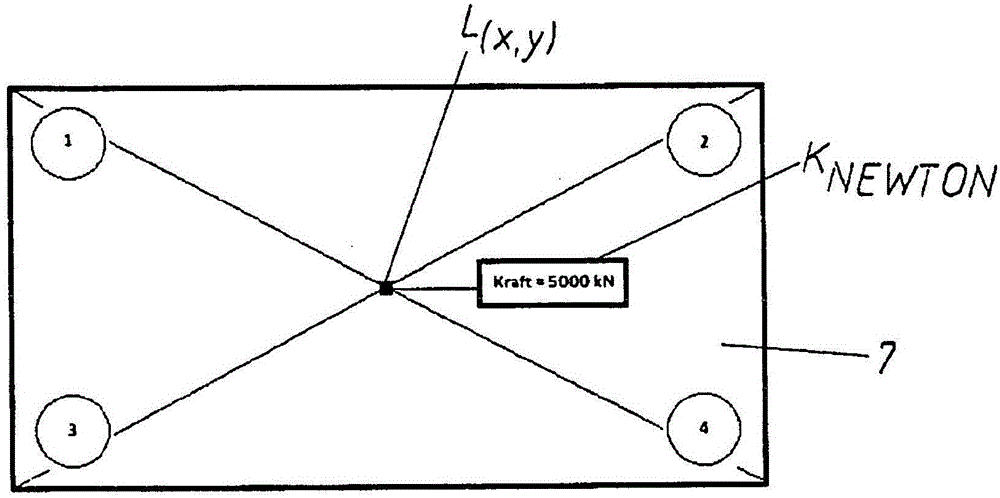

[0022] figure 1 A molding machine 6 is shown in the form of a vertical injection molding machine. The molding machine has a fixed mold clamping plate 8 , which is supported on supports, not shown. In addition, parallel to the fixed mold clamping plate 8, a movable mold clamping plate 7 is provided, which can move vertically along the beams 1 and 2 (and beams 3 and 4, which are not visible here). direction of movement. This vertical movability takes place via snap-action reciprocating devices 15 , which are formed, for example, as hydraulic piston-cylinder units. The distance D between the mold clamping plates 7 and 8 can be varied by means of a snap-action shuttle 15 .

[0023] In the upper region of the beams 1 and 2 are formed recesses and protrusions which cooperate with the recesses and protrusions of the connecting sleeve 17 . Together with a drive 16 , preferably a hydraulic piston-cylinder unit, this connecting sleeve 17 forms a locking device 18 for locking the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com