Lipid-rich microalgal flour and method for preparing same

A technology of microalgae powder and lipid-rich, applied in medical raw materials derived from algae, food science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0208] Example 1. Obtaining Chlorella protothecoides microalgal biomass by fermentation

[0209] The fermentation protocol is a modification of that substantially fully described in patent application WO2010 / 120923.

[0210] A preculture of Chlorella protothecoides was used to inoculate the production fermenter. The volume after inoculation reaches 9000 l.

[0211] The carbon source used was 55% w / w glucose syrup sterilized by applying a time / temperature protocol.

[0212] The fermentation was a feed-batch fermentation during which the glucose flow rate was adjusted to maintain a residual glucose concentration of 3 g / l to 10 g / l.

[0213] Production fermenter time is 4 to 5 days.

[0214] At the end of the fermentation, the cell concentration reached 185 g / l.

[0215] During the glucose feed period, nitrogen content in the medium was limited to allow accumulation of lipids in an amount of 50%.

[0216] The fermentation temperature was maintained at 28°C.

[0217] The pH ...

example 2

[0228] Example 2. Homogenized "Oil-in-Water" Emulsion of Dried Microalgal Flour

[0229] The homogenized emulsion obtained in Example 1 was dried in the following equipment:

[0230] -Single-effect spray dryer sold by GEA Nile (liquid dried by single-effect spray dryer is passed through a hot stream and then recovered in the bottom of the cyclone or sleeve filter) to obtain commercially available control microalgae pink.

[0231] or

[0232] - a flat-bottomed spray dryer equipped with an internal air broom for purging the spray drying chamber with low-pressure air to obtain the microalgae powder according to the invention,

[0233] The control single-effect spray drying operating conditions are as follows:

[0234] - the input temperature is 160°C,

[0235] - the temperature of the drying section is 60°C,

[0236] - Air cooling temperature: 21°C

[0237] -Output temperature: 60°C.

[0238] For the spray-drying process of the present invention, it involves spraying the h...

example 3

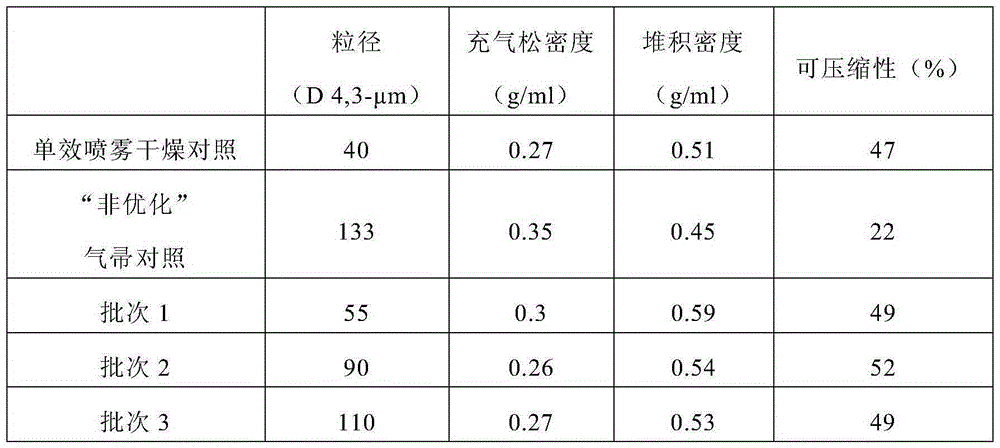

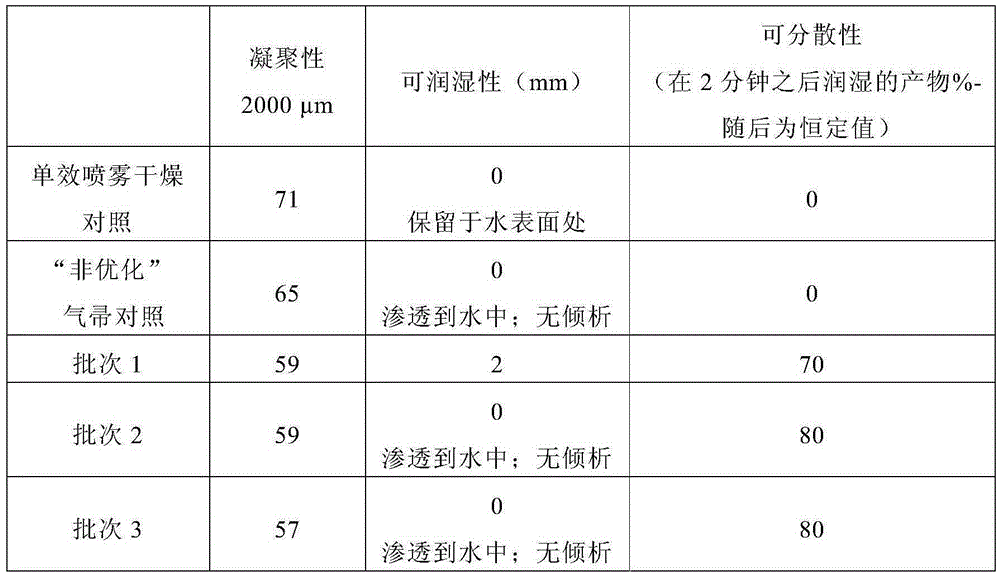

[0263] Example 3. Characterization of the microalgal flour of the present invention

[0264] In the table below, the following parameter values are presented:

[0265] - particle size,

[0266] - compressibility,

[0267] -Flowability, passed coagulation test (2000μm)

[0268] - wettability,

[0269] -Water dispersibility

[0270] For the "single-effect spray drying" control, for the non-optimized "air broom" control and for three batches of microalgae powder of the present invention.

[0271]

[0272]

[0273] Quite logically, it was observed that conventional microalgal flour characterized by "cohesive" particles (the "single effect spray-dried" control) would not become sufficiently hydrated to decant, while the microalgal flour of the present invention facilitates this , regardless of its cohesive characteristics. Thus, conventional microalgal flour deposits on the water surface without penetrating into the water. In contrast, the microalgal flour of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com