Corn husk pulverator and corn harvesting machine with same

A technology of corn husks and shredders, which is applied to cutters, harvesters, agricultural machinery and implements, etc., and can solve problems that affect the field's deep plowing, scattering, and crushing of corn husks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

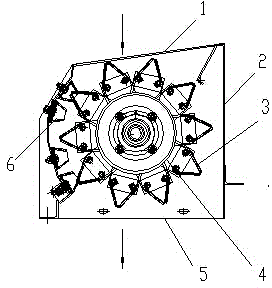

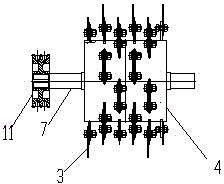

[0015] The present invention will be further described in detail in conjunction with the accompanying drawings. The corn husk chopper includes a housing 2 and a shredding stick 4. The housing 2 is connected to the shredding stick 4 in the housing 2. The transmission wheel 11 is fixedly connected with the chopping stick shaft 7 located on the outside of the housing, and also includes a moving blade 3 and a static blade 6. The housing is provided with an inlet 1 and an outlet 5, and the static blade 6 is fixed on the housing 2 Inside one side, the movable blade 3 that matches with static blade 6 is arranged in a staggered manner on the chopping stick surface corresponding to static blade 6 .

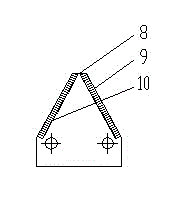

[0016] In order to further improve the cutting effect of the blade, the movable blade 3 and the static blade 6 are arranged in a trapezoidal shape.

[0017] In order to further improve the cutting effect of the blade, one side of both sides of the movable blade 3 and the static blade 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com