Corn straw inter-ridge crop rotation returning machine

A corn stalk and body technology is applied to the field of corn stalk inter-ridge cropping and returning machines, which can solve the problems of inability to perform sloped field operations, time-consuming and labor-intensive, manual operations, and the like, and achieve the effect of improving the effect of returning to the field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

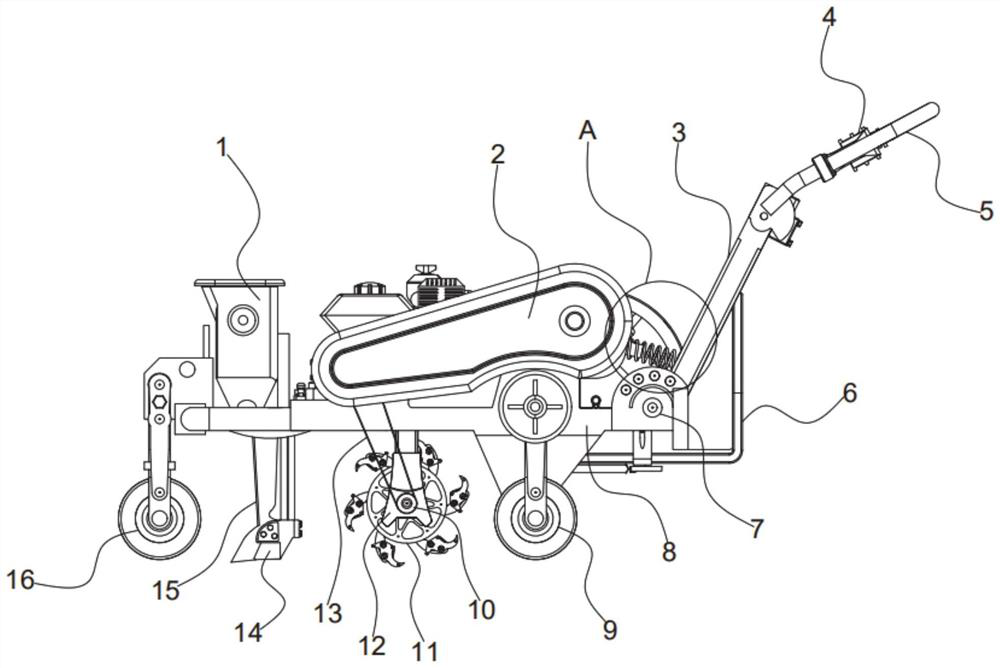

[0025] Example: see attached Figure 1-4 , the present invention provides a technical solution: a machine for returning corn stalks to the field in rotation between ridges, which includes:

[0026] Body 8, the front part of the body 8 is fixedly provided with a front drive wheel mechanism 16, and the rear part of the body 8 is fixedly provided with a rear drive wheel mechanism 9;

[0027] There are two control handle components, and the two control handle components are fixedly arranged on the rear end of the body 8;

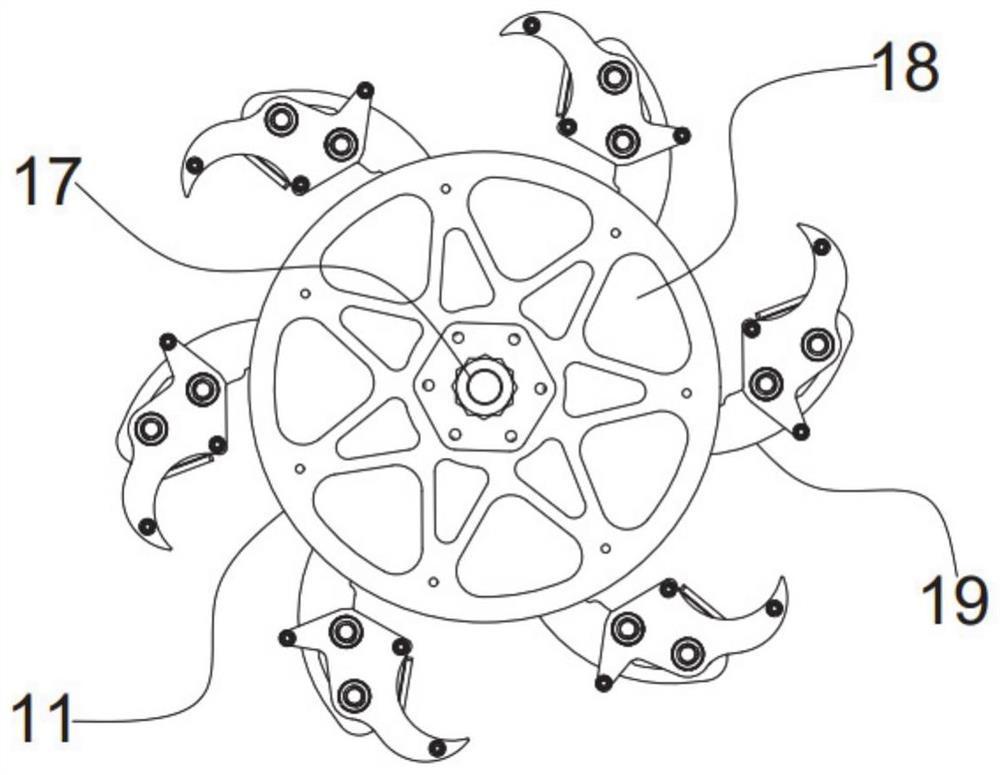

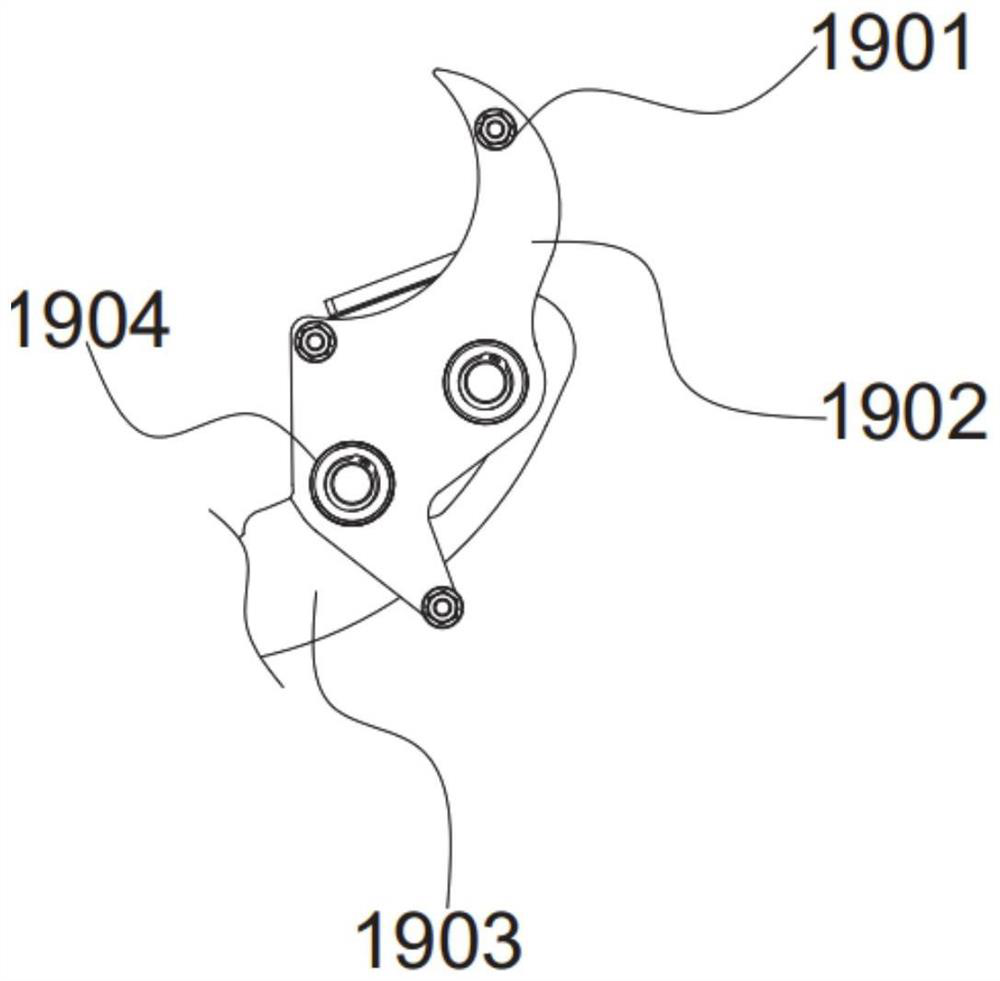

[0028] There are two pressure roller connection seats 12, two pressure roller connection seats 12 are symmetrically arranged on the bottom end surface of the middle part of the body 8, and a rotating shaft 17 is rotatably installed between the two pressure roller connection seats 12, A pressing roller 11 is fixedly sleeved on the rotating shaft 17, and a plurality of evenly arranged soil crushing assemblies 19 are fixed on the outer surface of the pressing roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com