Double-barrel Straight Straw Returning Machine

An in-line and in-line technology, applied to harvesters, crop processors, agricultural gas emission reduction, etc., can solve the problems of straw not rotten, affecting seeding operations, straw omission, etc., and achieves strong adaptability and return to the field. Good, big dose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

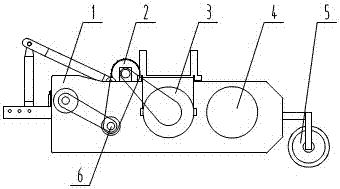

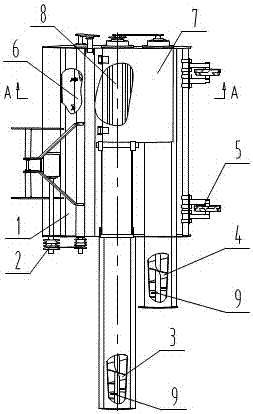

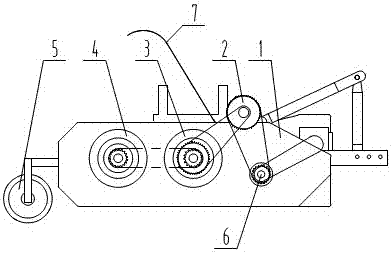

[0015] like figure 1 , figure 2 , Figure 5 As shown, a schematic diagram of the structure of the double-tube straight row straw returning machine of the present invention is given, including a frame 1, a transmission system 2 installed on the frame 1, and a depth-gauge wheel 5. A crushing roller 6 is provided rotatably laterally. Located behind the crushing roller 6 and parallel to the crushing roller 6, a front straight row cylinder and a rear straight row cylinder are arranged side by side. Protrude vertically, and the front straight row cylinder and the rear straight row cylinder are arranged along the transverse steps. On the center plane of the transverse width direction of the crushing roller 6, the front straight row cylinder is provided with a transverse partition, and the transverse partition and the described The side wall plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com