A bending springback compensation mold

A technology of mold and bending back, which is applied in the field of stamping molds, can solve problems such as the inapplicability of parts, and achieve the effect of eliminating stamping marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

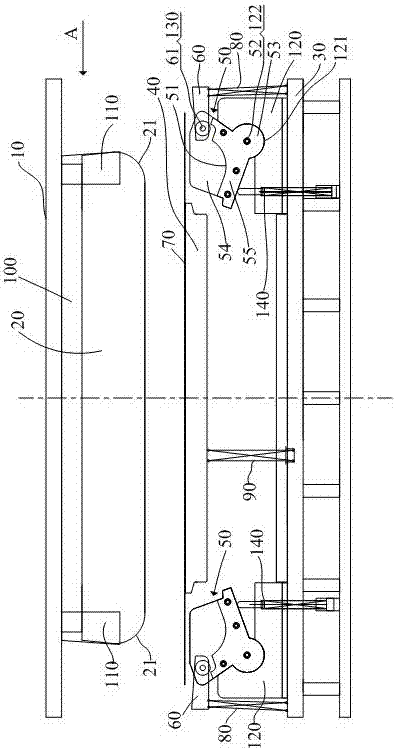

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

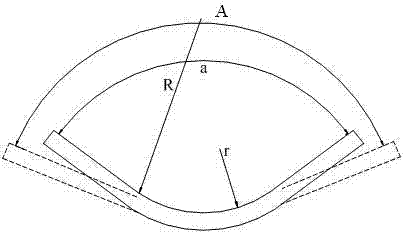

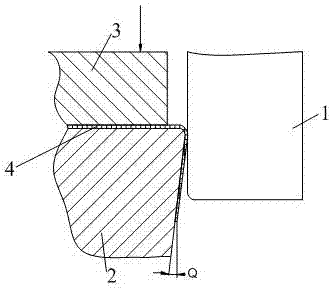

[0026] refer to Figure 3 to Figure 6 , a bending springback compensation mold in this embodiment includes an upper mold and a lower mold. The upper mold includes an upper mold base 10 and a punch 20 arranged on the upper mold base 10. The punch 20 has a bending angle with the workpiece. The bottom angle 21 is matched, and has a bending compensation angle Q; the lower mold includes a lower mold base 30, a lower stripper plate 40, a stripper plate return spring 90 and a rotatable swing at the left and right ends of the lower stripper plate 40 The die 50, the swing die 50 can be installed on the lower die base 30, and has a bending groove 51 adapted to the bottom angle 21 of the punch. Reset mechanism 140, on the swinging die 50, a swinging block 60 is swingably installed, and the swinging fulcrum 61 of the swinging block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com