Silica vacuum insulation panel coiling process

A technology of vacuum insulation panels and silicon dioxide, which is applied in the field of silicon dioxide vacuum insulation panels curling process and related equipment, can solve the problems of many scrapped products, high labor intensity, and inability to precisely control the external dimensions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0028] see Figure 1-5 :

[0029] A silicon dioxide vacuum insulation panel crimping process, comprising the following process steps:

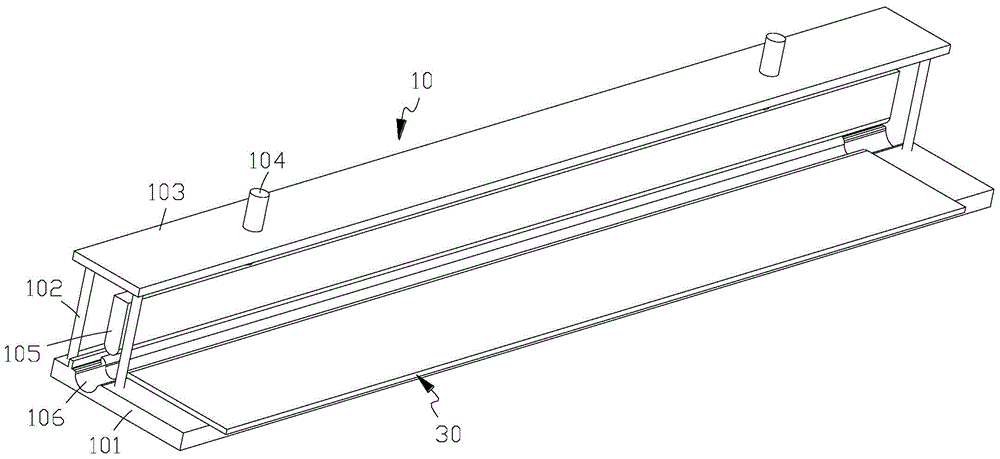

[0030] 1) Using a C-shaped up and down reciprocating pneumatic preloading device 10 to prepress one end of the silicon dioxide vacuum insulation panel 30 in the width direction into a "C-shaped" shape;

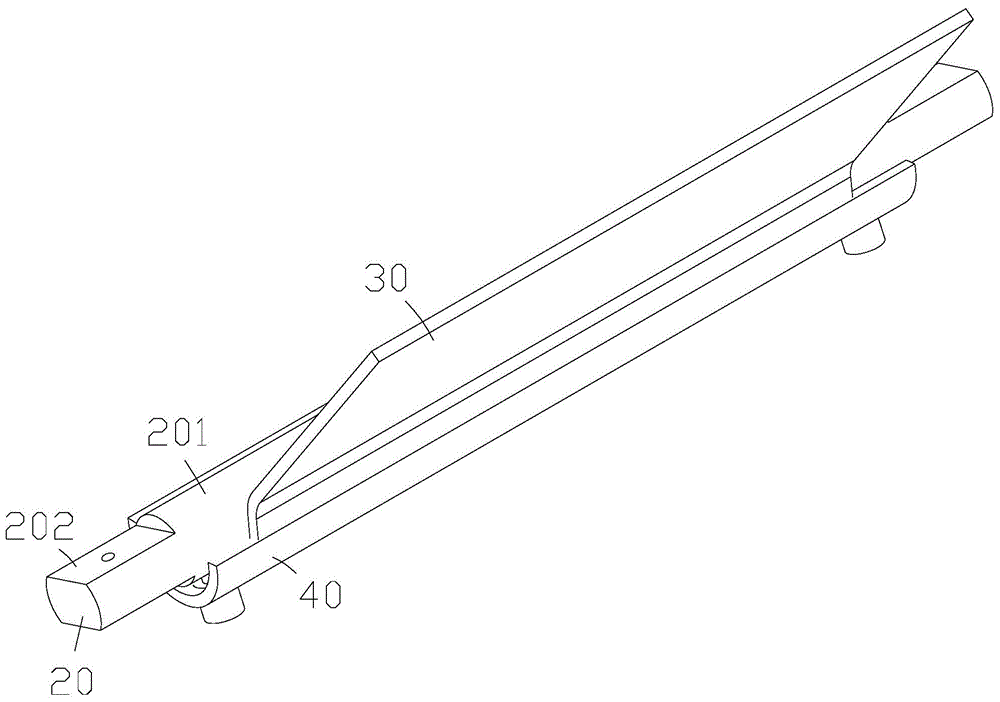

[0031] 2) Place the quick-change cylindrical shaft 20 inside the pre-pressed "C-shaped" silica vacuum insulation panel 30, place the outside of the silica vacuum insulation panel 30 in the C-shaped clip 40, and screw the The outer C-shaped clip 40, the silicon dioxide vacuum insulation panel 30 pre-pressed into a "C-shaped" at one end, and the quick-change cylindrical shaft 20 are fixed;

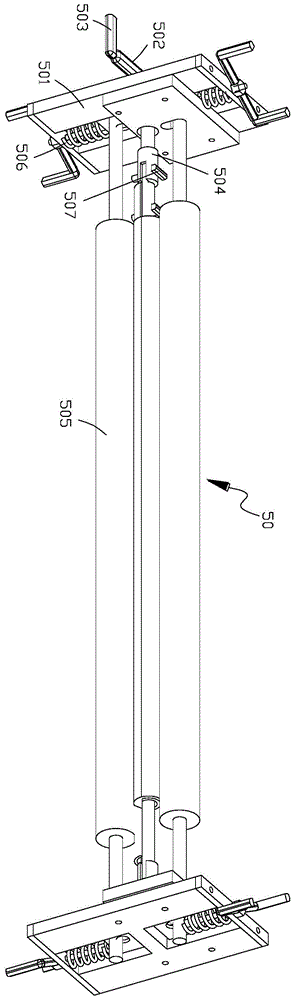

[0032] 3) Install o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com