Mold turnover machine

A technology of mold turning and mold machine, which is applied in the direction of hoisting device and hoisting device, can solve the problems of mold or staff injury, unstable lifting mold, easy and improper operation, etc., and achieves improved maintenance efficiency, reasonable and compact structure, Design simple and ingenious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

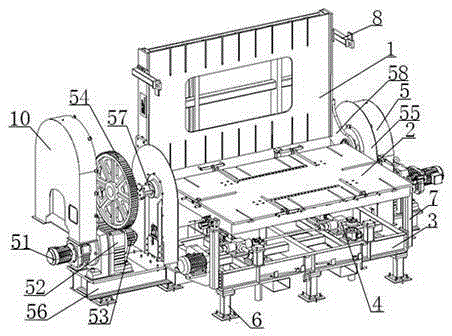

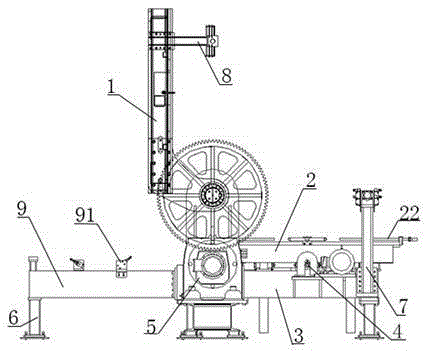

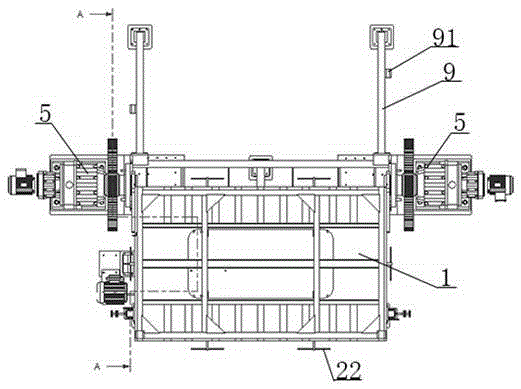

[0020] Refer to attached figure 1 , a mold turning machine, which includes an upper workbench 1, a lower workbench 2, a base 3, a lifting mechanism 4, and a turning mechanism 5. The base 3 is equipped with a foot 6, the middle of the base 3 is equipped with a lifting mechanism 4, and the upper end of the lifting mechanism 4 is installed. There is a lower workbench 3, lower safety supports 7 are installed on both sides of the front end of the base 3, slide rails are installed on the inner side of the lower safety support 7, sliders are installed on both sides of the front end of the lower workbench 2, and the sliders are slidably connected with the slide rails. Turning mechanism 5 is equipped with respectively at both ends, and turning mechanism 5 comprises motor 51, speed reducer 52, pinion 53, bull gear 54, turning support 55, bearing 56, and bearing 56 is contained in base 3 one side, and bearing 56 and Turning support 55 is housed between base 3, and cantilever support 59 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com