Foamable personal care composition comprising a continuous oil phase

A personal care and composition technology, applied in the direction of skin care preparations, cosmetics, cosmetic preparations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 10

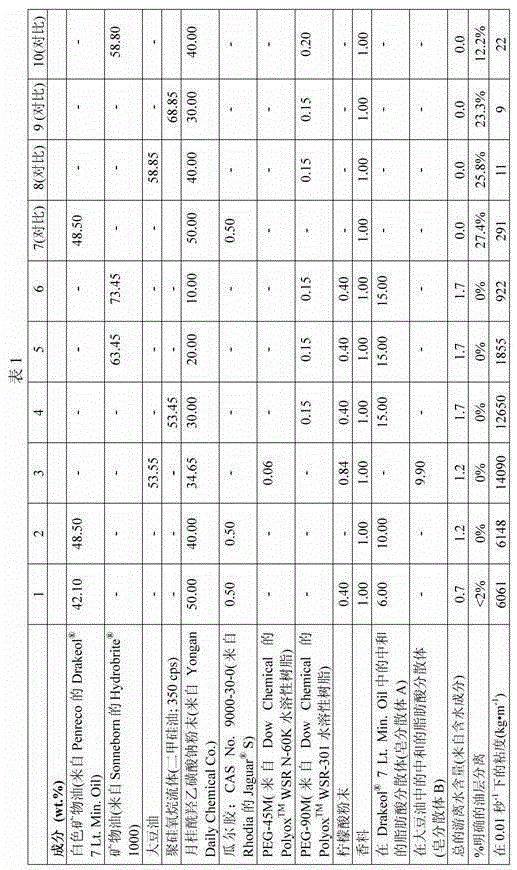

[0114] Sodium lauroyl isethionate (SLI) powder (from Yongan Daily Chemical Co.) was used to prepare a series of cleaning composition formulations described in Table 1. The neutralized fatty acid dispersions reported as ingredients were prepared by mixing 47.4 parts of the indicated oil, 21.6 parts of lauric acid, 10.8 parts of myristic acid and 3.6 parts of stearic acid in a mixer equipped with a 3-blade overhead mixer. (IKA) in a vessel and heat the resulting oil / acid mixture to 70-75oC with stirring; when all the fatty acids have dissolved (indicated by the formation of a clear solution); dissolve 16.6 parts of A 45 wt% solution of KOH in water was slowly added to the fatty acid / oil solution to neutralize the fatty acid; after mixing for an additional 5 minutes at 70°C, the mixture was cooled to ambient temperature to produce a dispersion of fine soap crystals in the oil .

[0115] Table 1 formulations were prepared by first adding the indicated oil components to a glass ja...

Embodiment 11- Embodiment 18

[0119] The effect of surfactant particle size on stability was evaluated in compositions having relatively low levels of fatty acid soap. In this series of examples, sodium cocoyl isethionate (SCI) (Jordapon ? CI pellets from BASF) were crushed and classified. Particles with sizes <2000 to 500 μm; <500 to 300 μm; <300 to 180 μm; <180 to 75 μm, <75 to 45 μm; and less than 45 μm were collected for sample preparation, respectively. For the reported fractions, the particles were passed through a sieve with a mesh size corresponding to the highest value in the range and retained in a sieve with a mesh size corresponding to the lowest value in the range. on a sieve. For example, particles in the range <2000 to 500 μm pass through a sieve with a mesh size of 2000 μm and are retained on a sieve with a mesh size of 500 μm.

[0120] Formulations as described in Table 2 were prepared and their stability was measured following the procedure described in the previous examples.

[0121]...

Embodiment 19- Embodiment 31

[0124] Examples 19-31 show the effect of soap neutralization on viscosity in various oil / surfactant compositions.

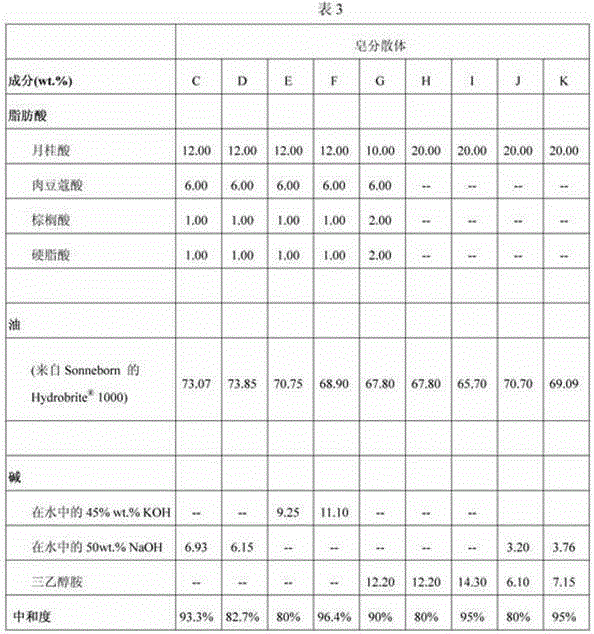

[0125] The fatty acid soap dispersions used in these examples were prepared according to the formulations given in Table 3 by combining the indicated fatty acids and mineral oil in a glass jar equipped with a 3-blade overhead mixer and mixing the The resulting oil / acid mixture was heated to 70-75°C; when all the fatty acids had dissolved (indicated by the formation of a clear solution), the indicated base was slowly added to neutralize the fatty acids; after all the base had been added, the mixture was cooled to At ambient temperature, a dispersion of fine soap crystals in the oil results.

[0126]

[0127] Using BlendTec TM The Model ICB7 High Speed Mixer prepared the surfactant premixes mentioned in Table 4 and Table 5 in oil at the indicated loadings. To prepare the premix, cycle surfactant powder and mineral oil (Hydrobrite ? 1000 from Sonneborn) into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap