Assembly machine and method for the manufacture of rod-shaped articles for the tobacco processing industry

A technology for assembly machines and shaped products, which is applied in the manufacture of cigarettes, tobacco, applications, etc., can solve the problems of unmanufacturable products and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

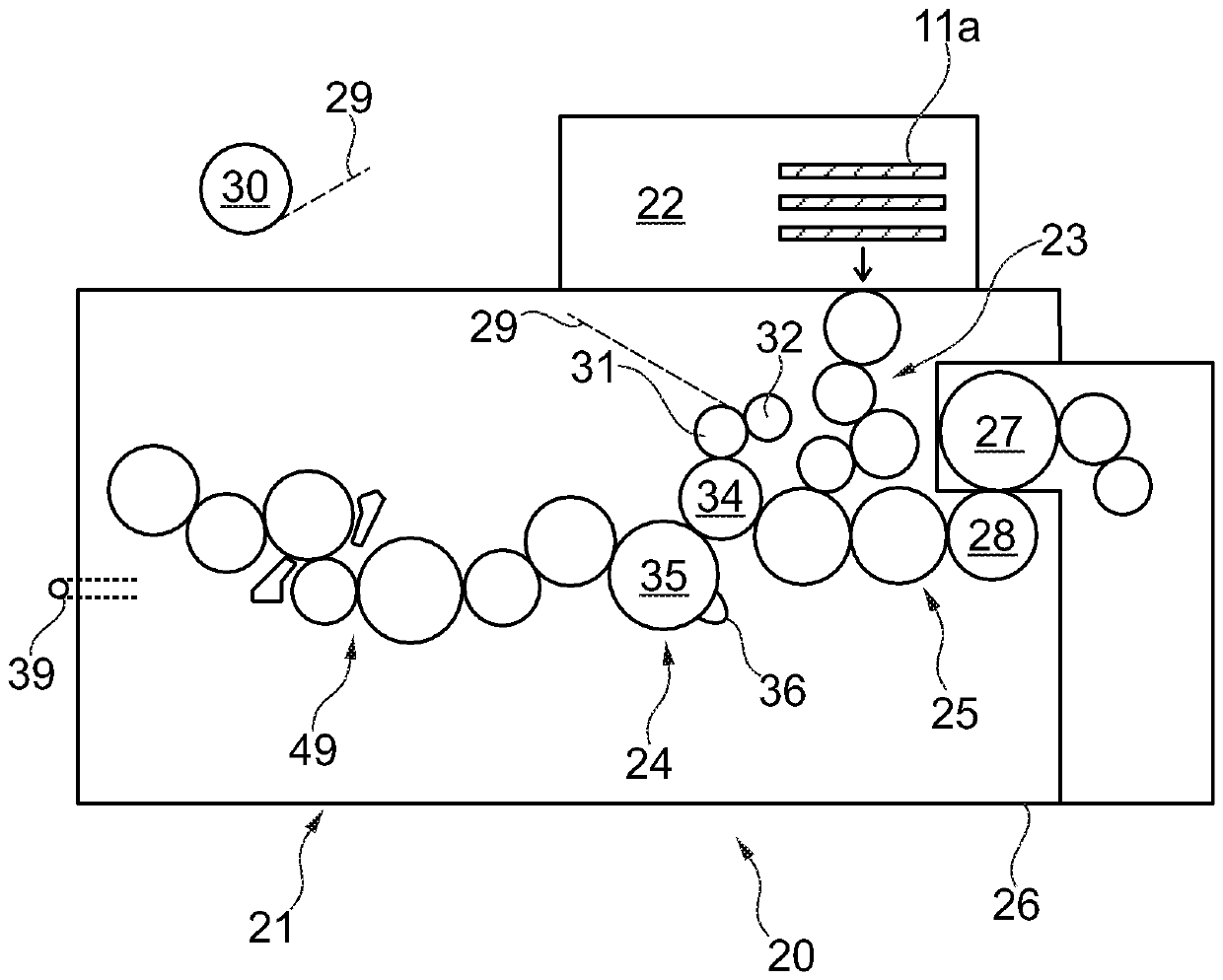

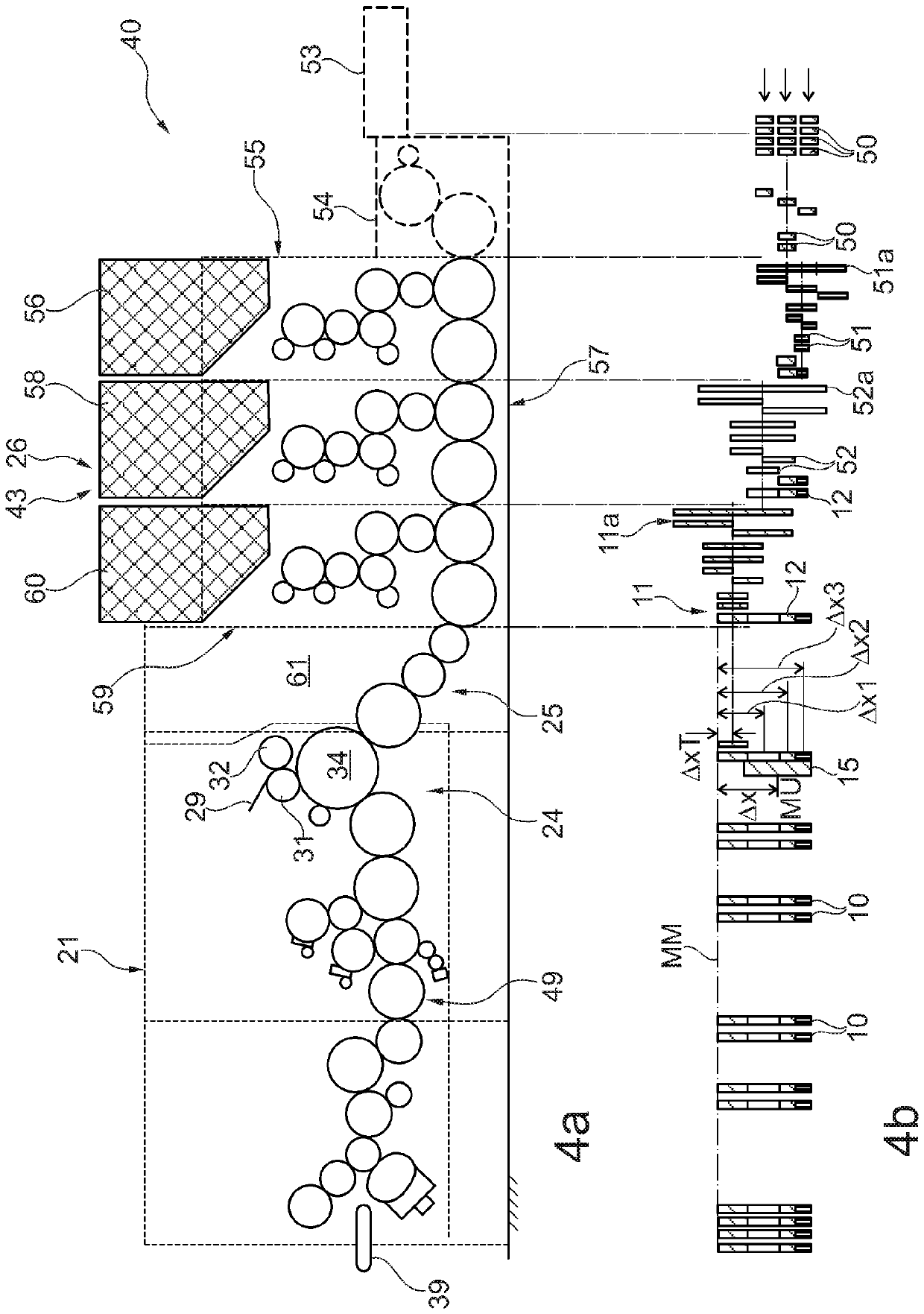

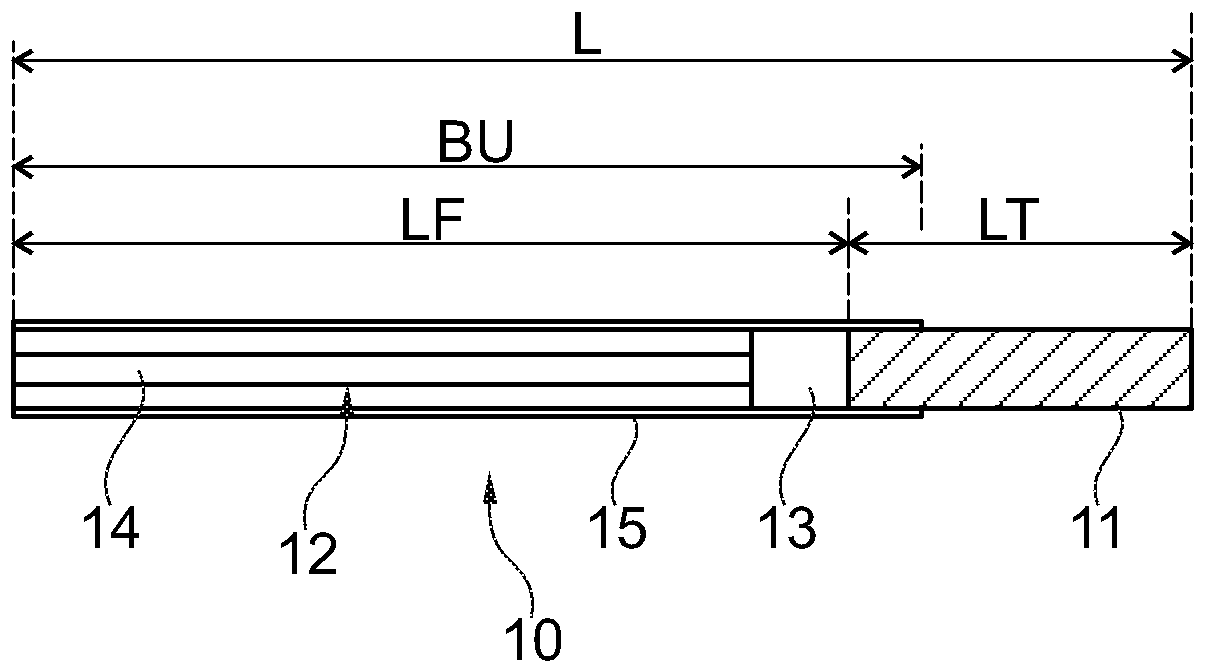

[0017] figure 1 A tobacco product 10 in the form of a rod is schematically shown, which has a very different construction from conventional filter cigarettes. The tobacco product 10 has a relatively short tobacco rod 11 of length LT and a relatively long filter rod 12 of length LF, which here consists of two segments 13, 14, but can also consist of more than two A segment, in particular, for example consists of three segments (see below). The length LF of the filter rod 12 is in particular greater than the length LT of the tobacco rod 11 . The filter rod 12 is fixed on the tobacco rod 11 by means of a relatively wide paper covering 15 with a width of BU>LT. The total length L = LT + LF may correspond to the length of a conventional filter cigarette. The width BP of the paper covering strip 29 does not allow the conventional processing of double-length rod-shaped products with a centrally arranged, double-width paper covering sheet 15 in a conventional filter assembly machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com