Container wall board structure

A container and wall panel technology, which is applied in the field of container wall panel structure, can solve the problems of waste of materials and high cost, and achieve the effects of reducing cost, light weight and overall light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

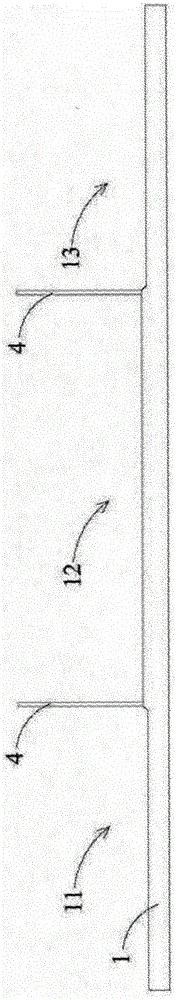

[0046] like figure 2As shown, the second embodiment of the container wall panel structure of the present invention differs from the first embodiment of the container wall panel structure mainly in that:

[0047] The second embodiment also includes two bulkheads 4 fixed to the top beam 1 and the wall panel 2 . The two partitions 4 are respectively vertically welded to the front and rear ends of the middle region 12 of the container wall panel structure, and of course the two partitions 4 are vertically welded to the rear end and rear end of the front region 11 of the container wall panel structure respectively. In short, the two partitions 4 are respectively welded to the junction of the front region 11 and the middle region 12 and the junction of the middle region 12 and the rear region 13, so as to divide the regions with different section flexural modulus Just separate it.

[0048] The number of partitions 4 is not limited to two, and it can vary with the number of region...

Embodiment approach 3

[0054] like Figure 3A , Figure 3B As shown, the third embodiment of the container wall panel structure of the present invention differs from the first embodiment of the container wall panel structure mainly in that:

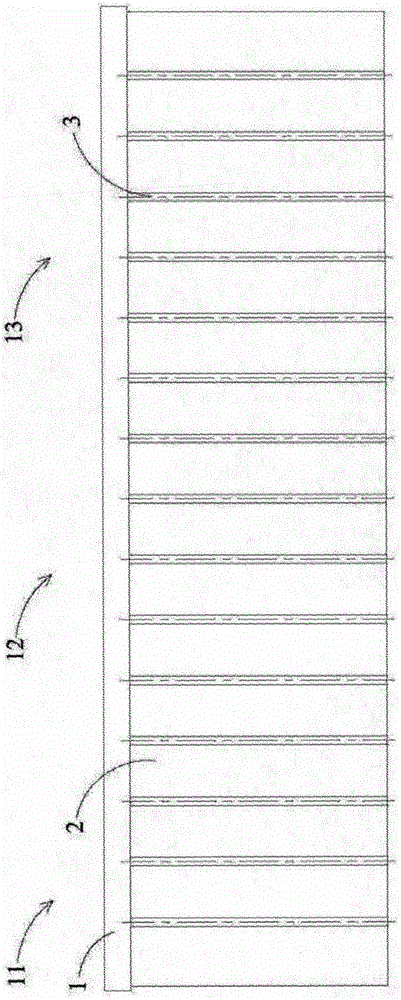

[0055] A plurality of reinforcing columns 3 are not uniformly fixed on the top beam 1 and the wall panel 2, but the distribution density corresponding to the middle area 12 of the container wall panel structure is greater than the distribution density corresponding to the front area 11 and the rear area 13, thus The section flexural modulus of the container wall panel structure in the central region 12 is greater than the section flexural modulus of the front region 11 and the rear region 13 .

[0056] In the third embodiment of the container wall panel structure, the cross-sectional flexural modulus of different regions is changed by changing the arrangement density of multiple reinforcing columns 3 in different regions, so as to adapt to the stress condition...

Embodiment approach 7

[0076] like Figure 7 As shown, the seventh embodiment of the container wall panel structure of the present invention differs from the first embodiment of the container wall panel structure mainly in that:

[0077] The wall panel 2 is a corrugated board, and the corrugation depth corresponding to the middle area 12 of the container wall panel structure is smaller than the corrugation depth corresponding to the front area 11 and the rear area 13, and of course the reverse is also possible.

[0078] Further, the inner surfaces of the corrugated plates are located on the same plane. Of course, the outer surfaces of the corrugated plates may also be located on the same plane (not shown).

[0079] In the seventh embodiment of the container wall panel structure, the section flexural modulus of different areas is changed by changing the corrugation depth of the corrugated plate in different areas, so as to adapt to the stress situation of different areas.

[0080] Other structures ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com