Glass wall

A glass wall and inner layer glass technology, applied in walls, building components, climate change adaptation, etc., can solve the problems of increasing the cost of glass and not being widely used, and achieve the effect of low manufacturing cost and improved quality of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment

[0013] The present invention is described further:

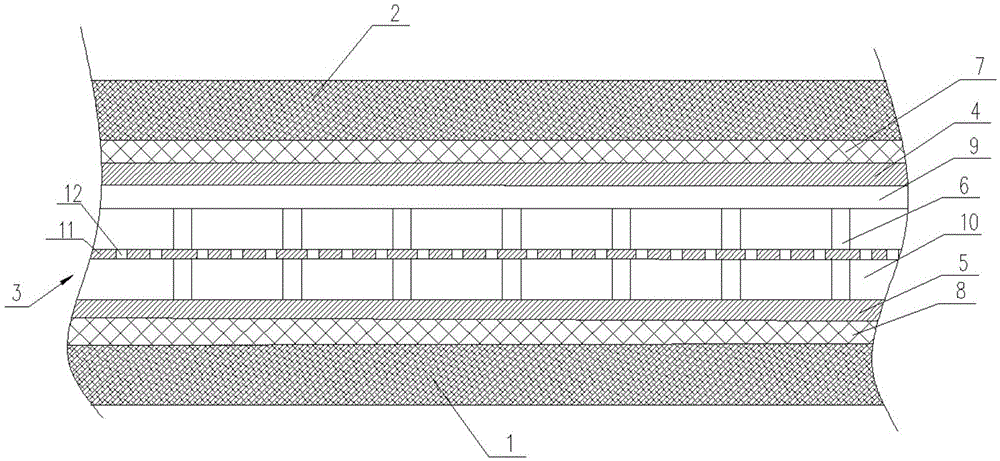

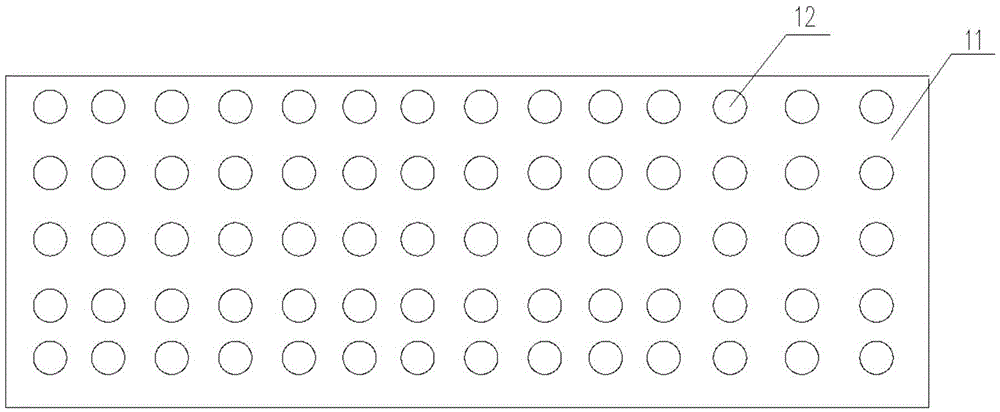

[0014] Such as Figure 1 to Figure 2 As shown, a glass wall includes an inner glass 1 and an outer glass 2, a transparent plastic interlayer 3 is arranged between the inner glass 1 and the outer glass 2, and the transparent plastic interlayer 3 includes a first transparent plastic plate 4 and the second transparent plastic plate 5, the first transparent plastic plate 4 and the second transparent plastic plate 5 are separated by support columns 6 to form an air chamber 10, and the first transparent plastic plate 4 is connected to the outer glass by the first adhesive layer 7 2 is fixed, and the second transparent plastic plate 5 is fixed with the inner glass 1 through the second adhesive layer 8.

[0015] An oxide heat insulating layer 9 is arranged on the contact surface between the first transparent plastic plate 4 and the support column 6, thereby hav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com