Inkjet head and printer

An inkjet head and ink technology, used in printing, inking devices, etc., can solve the problems of many parts boundary surfaces, ink intrusion into the inside of the cover and adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

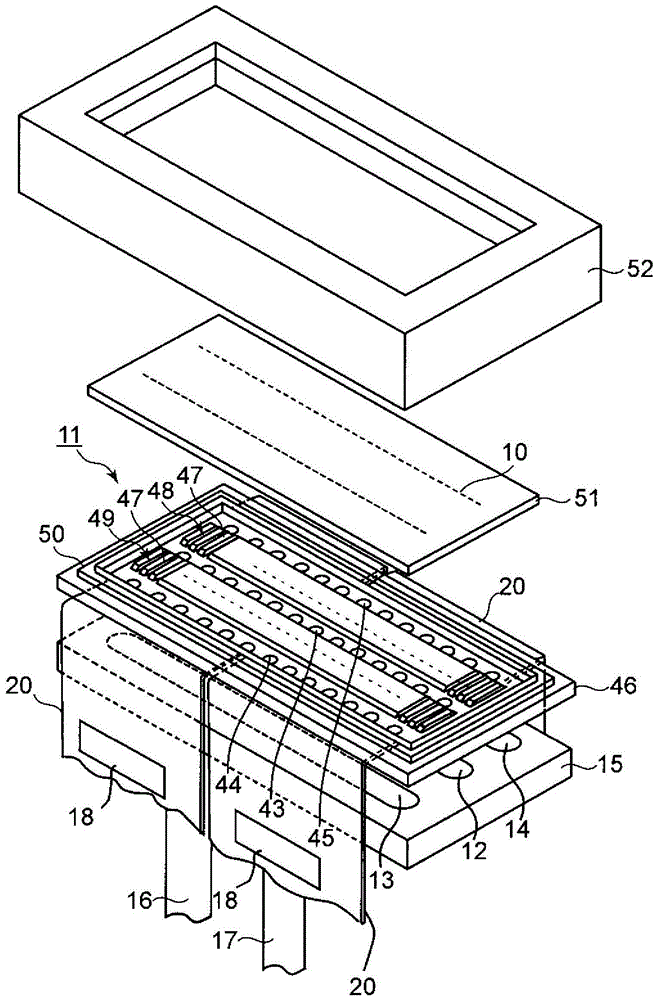

[0019] figure 1 It is an exploded perspective view of an inkjet head according to one embodiment. The inkjet head of this embodiment is provided with: a head body 11 having a plurality of discharge ports 10 for ink, a manifold 15 having an ink supply path 12 and ink discharge paths 13, 14 to the head body 11, and Connecting pipes 16 and 17 (pipes) communicating with the respective ink supply passages 12 and ink discharge passages 13 and 14 are provided at 15 in the pipe length direction perpendicular to the head body 11 .

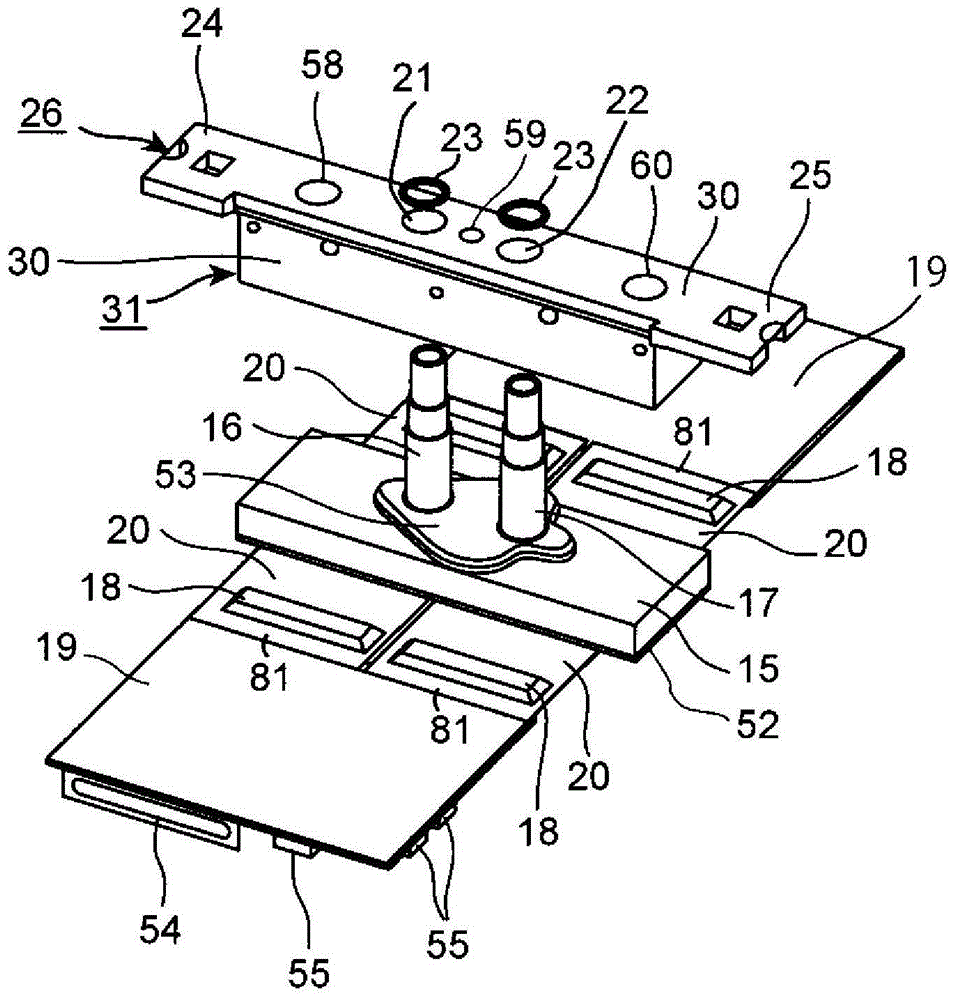

[0020] figure 2 is an exploded perspective view of part of an inkjet head according to an embodiment, and figure 1 The example of is displayed upside down. The symbols that have been described each represent the same element. The inkjet head of this embodiment is equipped with: four flexible substrates 20, which have a film (flexible) bent from a developed posture perpendicular to the tube longitudinal direction of each connecting tube 16, 17 to a curv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com