Method, Apparatus and System for Fatigue Life Evaluation of Micro-Interconnect Solder Joints under Comprehensive Stress

A fatigue life and comprehensive stress technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the misjudgment of fatigue life of micro-interconnect solder joints, cannot effectively locate solder joints, and is not conducive to flip-chip micro-interconnect solder joint structures. and material design optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

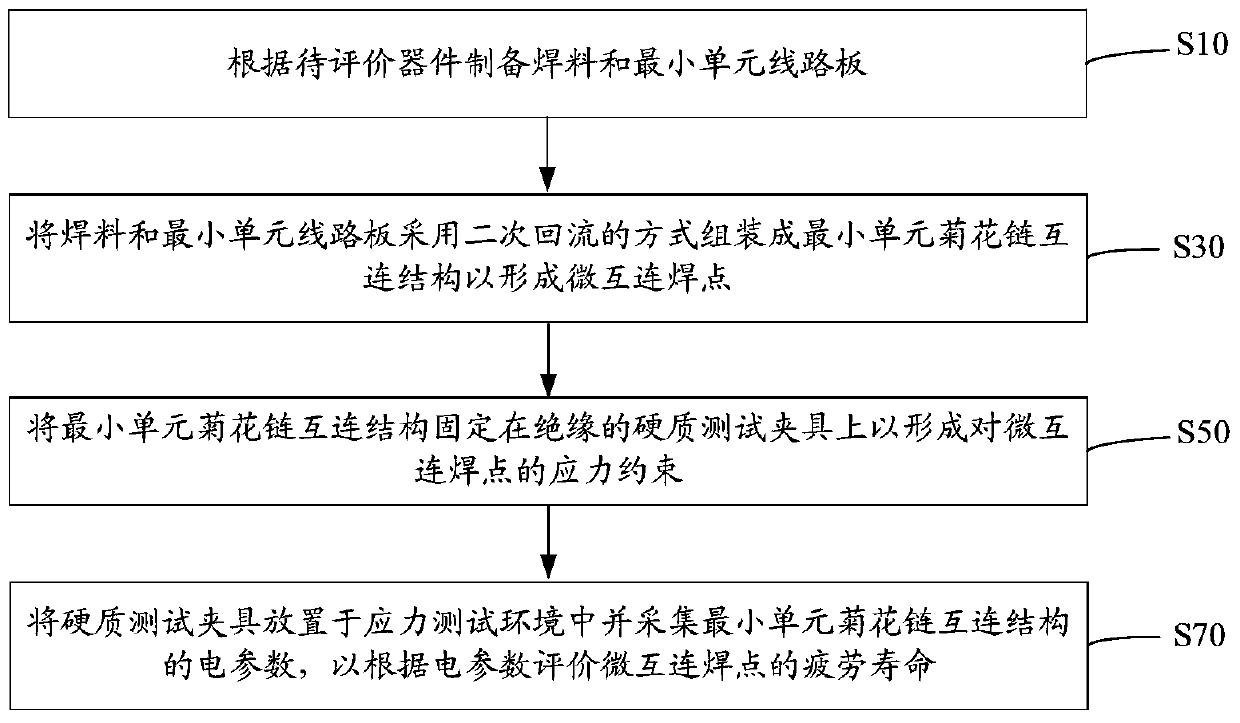

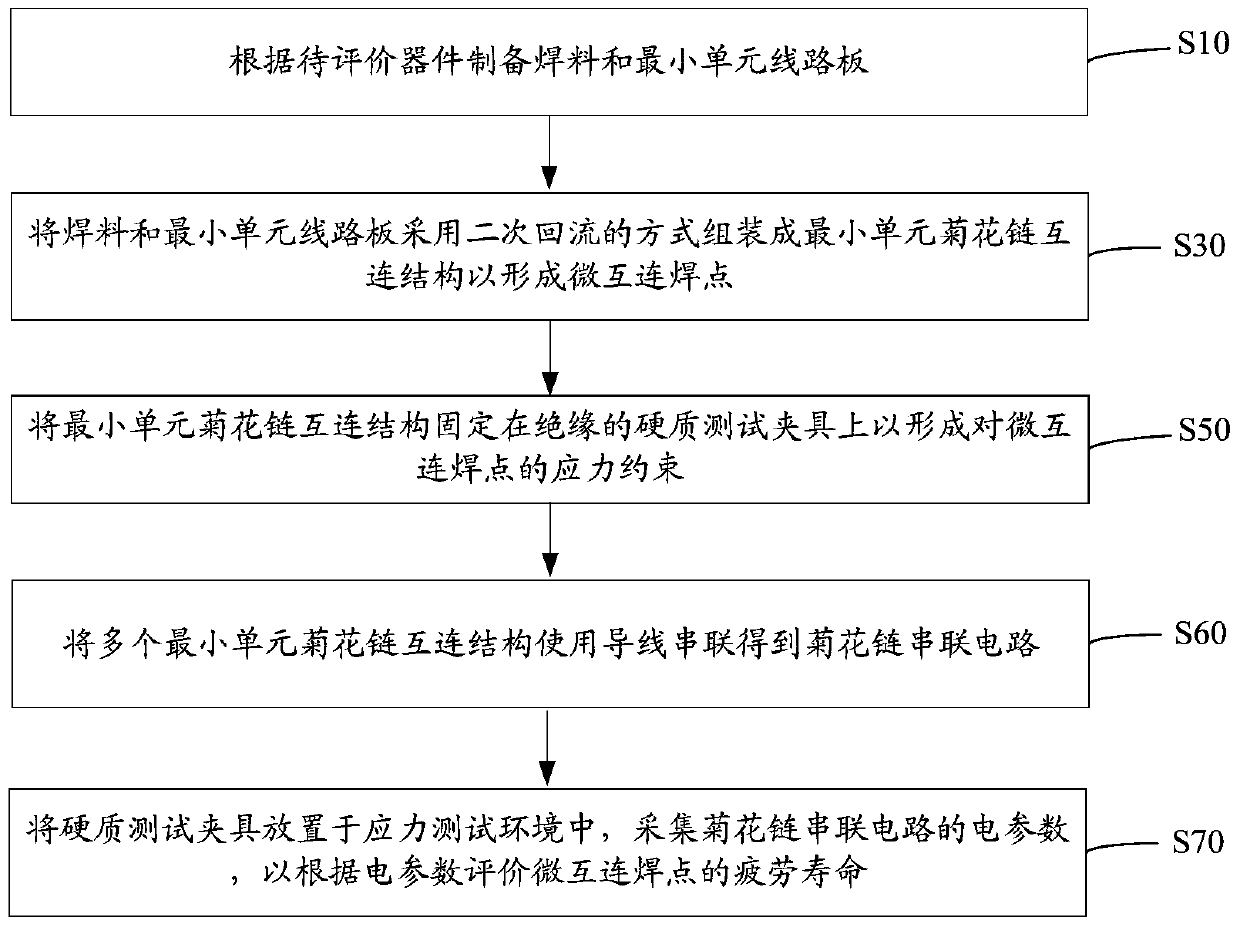

[0040] A fatigue life evaluation method of micro-interconnect solder joints under comprehensive stress, such as figure 1 shown, including the following steps:

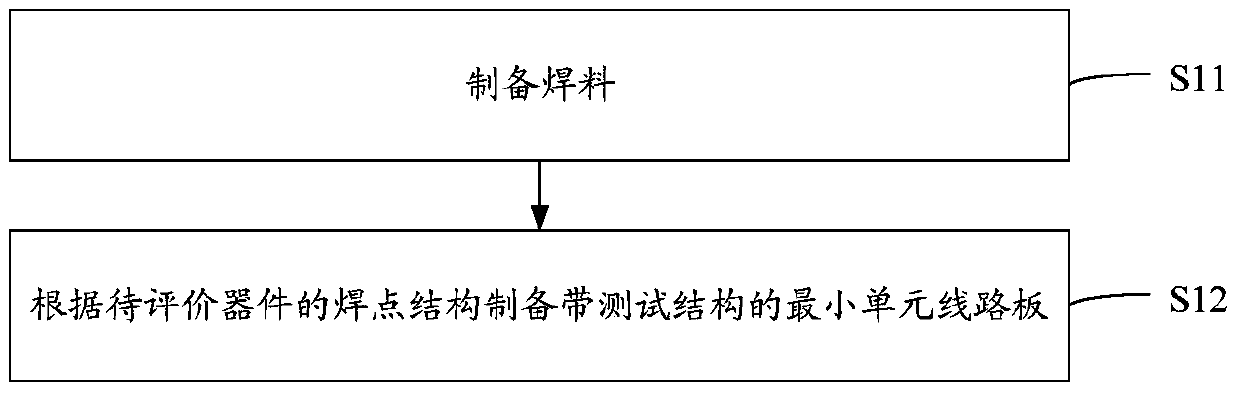

[0041] S10: Prepare solder and minimum unit circuit boards according to the device to be evaluated.

[0042] Specifically, suitable solder and minimum unit circuit boards are prepared according to the parameters of the device to be evaluated. For parameters, please refer to the technical data of the device to be evaluated.

[0043] S30: Assemble the solder and the minimum unit circuit board into a minimum unit daisy-chain interconnection structure by means of secondary reflow to form micro-interconnection solder joints. .

[0044] S50: Fix the minimum cell daisy-chain interconnect structure on an insulating rigid test fixture to form stress constraints on the micro-interconnect solder joints.

[0045] S70: Place a hard test fixture in a stress test environment and collect electrical parameters of the smallest unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com