Design method of vibration reliability of turbine leaf disc structure

A technology for turbine blisks and structural vibrations, applied in computing, special data processing applications, instruments, etc., can solve problems such as inability to quantify structural resonance, failure to ensure that turbine blisks avoid resonance, and failure to consider material dispersion, etc., to achieve turbine The effect of blisk structure optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

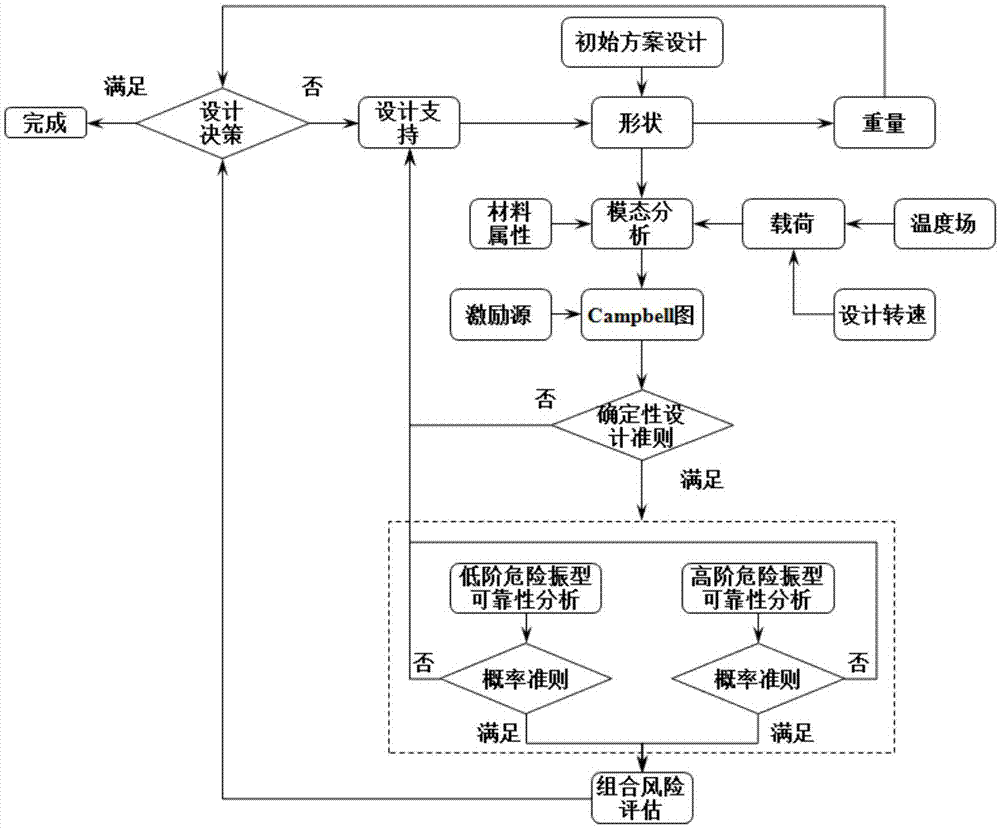

[0017] The technical solution of the vibration reliability design method of the turbine blade disc structure of the present invention will be further explained in conjunction with the accompanying drawings.

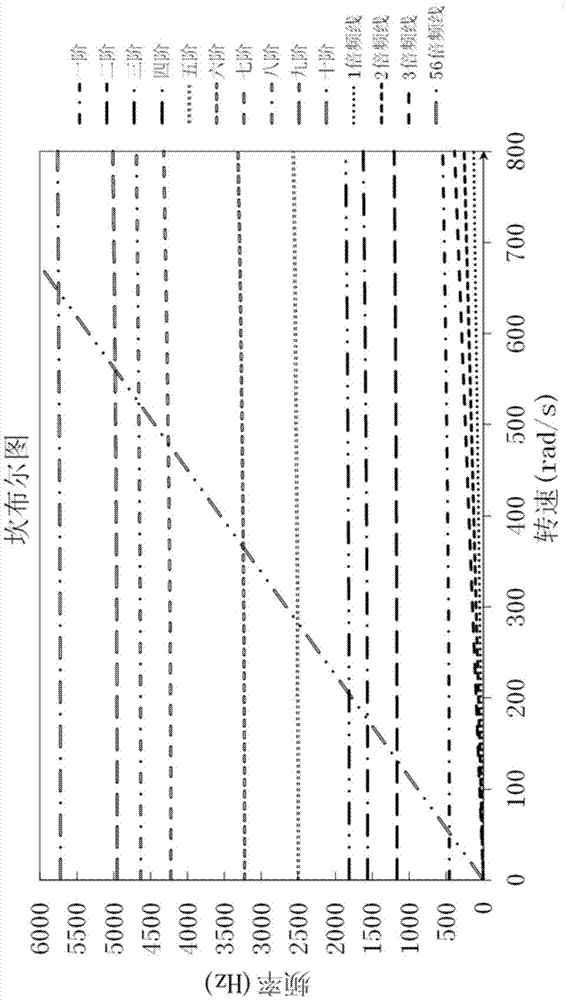

[0018] Considering the dispersibility of factors such as load, material and geometry, combined with the vibration reliability criterion of the turbine blade disc structure, the turbine blade disc structure vibration reliability design method provided by the present invention, the flow is shown in figure 2 .

[0019] (1) Initial plan design: first carry out the initial plan design, determine the preliminary structure according to the requirements of strength and aerodynamics, and make the resonance speed not fall near the engine design working speed or the engine stays at the resonance speed for a short time; calculate and determine The weight of the initial plan provides the initial weight for subsequent steps.

[0020] (2) Deterministic detailed design: Obtain the material pro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap