A Reliability Analysis Method of Turbine Disk Partition Based on Size Effect Correction

A size effect and analysis method technology, applied in special data processing applications, instruments, geometric CAD, etc., can solve the problems that it is difficult to accurately give the actual life of the structure and quantify the failure of the structure, and achieve accurate turbine disk life and reliability, quantification The effect of risk of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical scheme of the reliability analysis of the turbine disk partition based on the size effect correction of the present invention will be further described below in conjunction with the accompanying drawings.

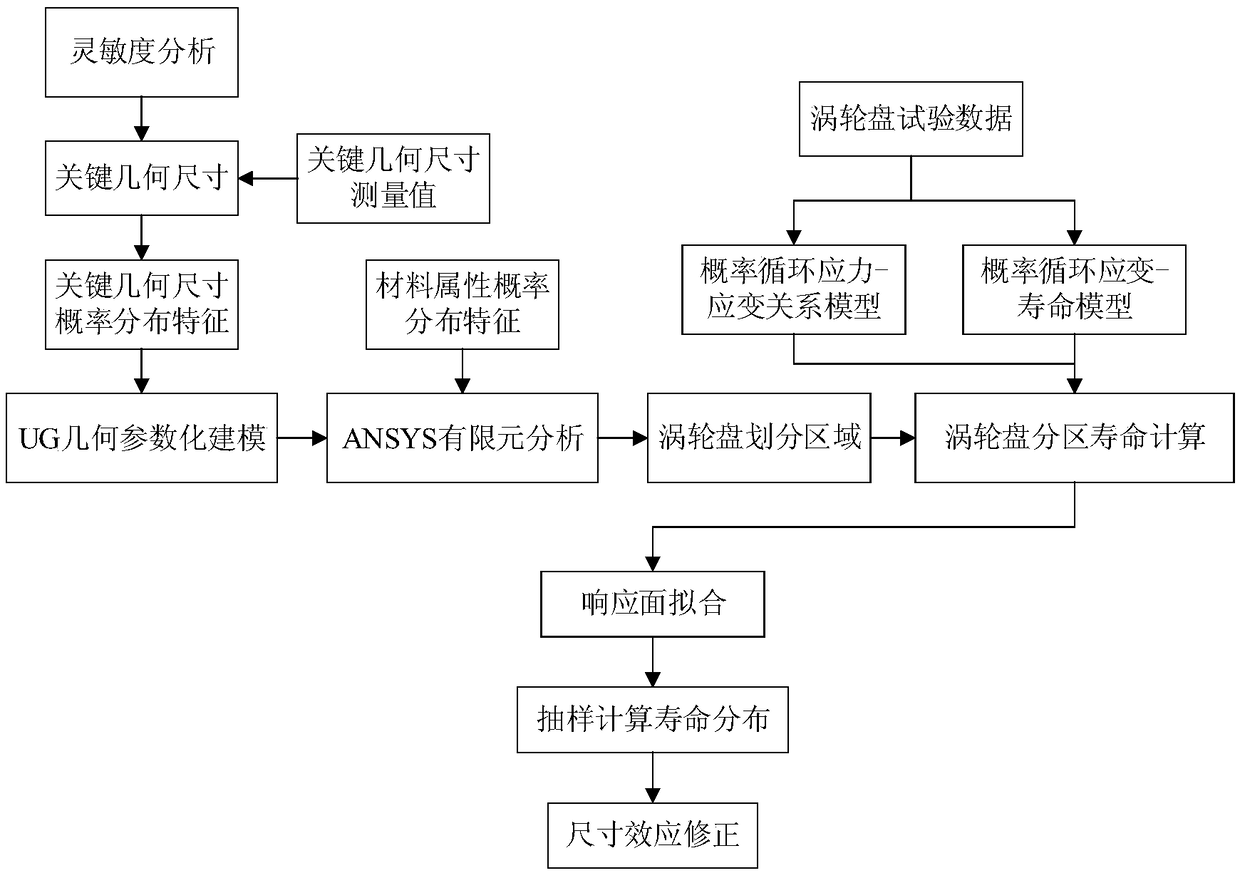

[0015] Consider the dispersion of factors such as materials and geometric dimensions, and carry out regional division and combined risk assessment on the turbine disk, combined with the life reliability analysis method of the turbine disk structure, the process is shown in figure 1 .

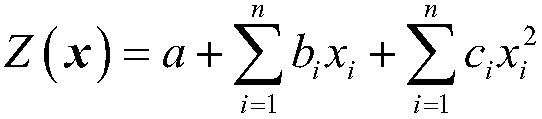

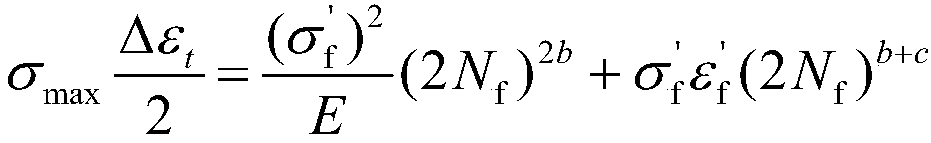

[0016] (1) Remove the small chamfers and bosses on the turbine disk to simplify the turbine disk model; conduct Latin hypercube sampling on all the geometric dimensions of the simplified turbine disk, generate samples of different geometric dimensions for finite element analysis, and use turbine The maximum equivalent stress of the disk is used as the output response, and a quadratic polynomial without cross terms is constructed as the response surface model, and its func...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com