Telescoping trimming rod

A telescopic and telescopic rod technology, which is applied in the direction of electric pruning saws, cutting tools, cutting equipment, etc., can solve the problems of inconvenient pruning operations, and achieve the effects of simplifying pruning operations, reducing storage space, and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

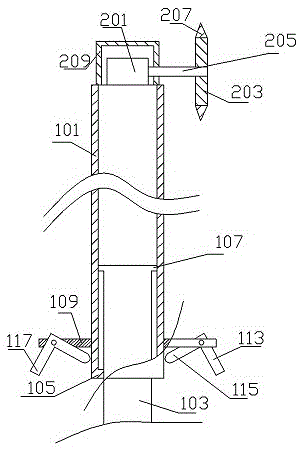

[0014] The reference signs in the drawings of the description include: upper pole 101, lower pole 103, horizontal plate 105, fence 107, connecting rod 109, positioning rod 113, positioning end 115, grip end 117, motor 201, disc 203, an output shaft 205, a sawtooth 207, and a casing 209.

[0015] Such as figure 1 The shown telescopic pruning rod includes a telescopic rod, a positioning mechanism and a shearing mechanism. The telescopic rod includes an upper rod 101 and a lower rod 103. The upper rod 101 is a hollow rod, and the upper rod 101 is sleeved on the lower rod 103. Outside, the inner wall of the bottom end of the upper pole 101 is provided with a horizontal plate 105, the side wall of the upper end of the lower pole 103 is provided with a fence 107, the lower end of the upper pole 101 is connected with a positioning mechanism, and the positioning mechanism includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com