Masonry wall movement joint fireproof and heat-preserving structure and installation method thereof

A deformation joint and masonry wall technology, applied in the directions of thermal insulation, fire prevention, building structure, etc., can solve the problems of single functional requirements, loss of thermal insulation effect, and single deformation form adaptable to deformation joint structure, so as to achieve a wide range of adaptability and meet construction requirements. Requirements, the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

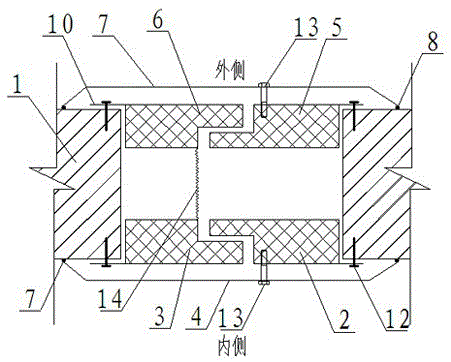

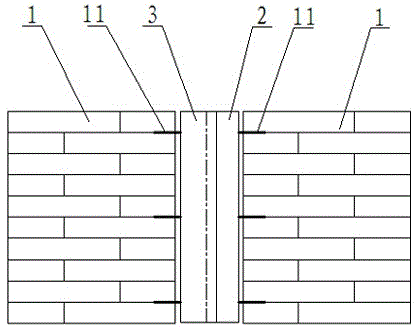

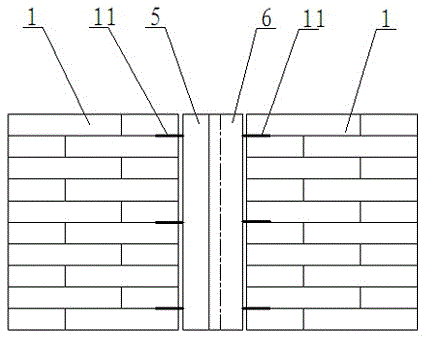

[0031] According to the accompanying drawings, a fire-proof and heat-preservation structure for deformation joints of masonry walls, an L-shaped fire-proof inner panel 2 and an L-shaped fire-proof outer panel 3 are arranged on the inner side of the wall, and the fire-proof inner panel 2 and the fire-proof outer panel 3 are connected to the wall through the tail 1. The base layer is connected and fixed, and a groove-shaped fireproof cover 4 is also provided on the inner surface of the wall 1. The fireproof cover 4 is fixed to the fireproof inner panel 2 by bolts 13. An L-shaped thermal insulation inner panel 5 and an L-shaped thermal insulation outer panel 6 are arranged on the outside of the wall. Both the thermal insulation inner panel 5 and the thermal insulation outer panel 6 are connected to the base layer of the wall 1 through tail fins. Cover plate 7, insulation cover plate 7 is fixed with insulation inner plate 5 by bolt 13. A tension spring 14 is arranged between the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com