Ceiling punch laser positioning apparatus

A positioning device and hole laser technology, which is used in measuring devices, instruments, mapping and navigation, etc., can solve problems such as troublesome positioning screw holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

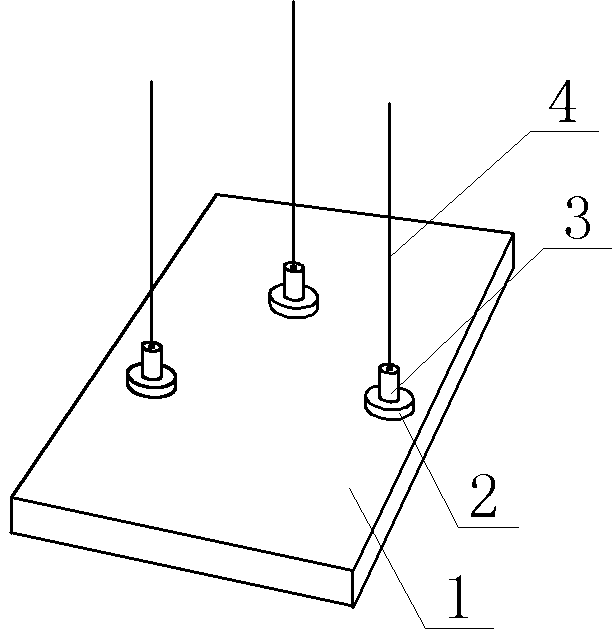

[0009] in figure 1 In the embodiment, we take the implementation of a ceiling drilling laser positioning device as an example to further illustrate the present invention:

[0010] figure 1 It is a schematic diagram of the structure of a ceiling drilling laser positioning device of the present invention. In the figure, the water platform 1 is a platform with a smooth surface. The length and width can be determined according to the specific situation. The surface can be made of flat iron plate. In order to reduce weight, The thickness of the iron plate can be thinner. The magnet 2 is a round magnet, as long as it can be firmly attached to the iron plate, but it needs to be flat on both sides. The laser transmitter 3 can be a point laser or a cross-hair laser, which is selected from the band It is more convenient to use a battery as a power source. Fix the laser transmitter 3 underneath the magnet 2 by bonding or other fixing methods. However, it is required that when the water pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com