Pressure staging in a continuously variable transmission

A derailleur, variable technology applied to elements with teeth, transmission controls, belts/chains/gears, etc., to address issues affecting subjective response and drive quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

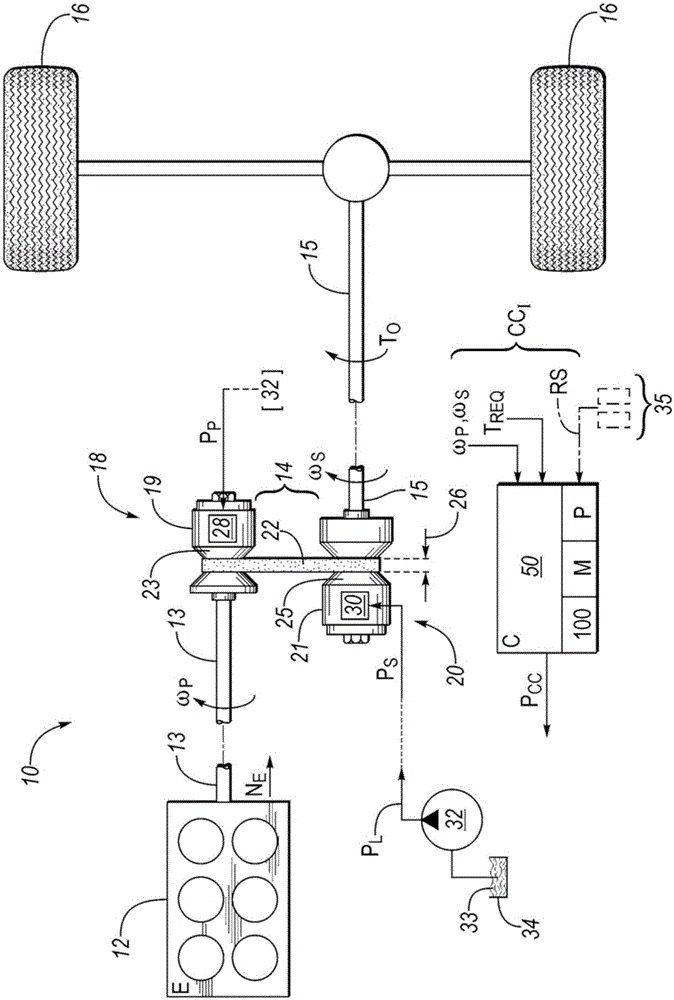

[0030] Referring to the drawings, wherein like reference numerals correspond to like or similar parts throughout the several views, figure 1 An example vehicle 10 is schematically shown in . The vehicle 10 includes a torque-generative device 12 shown as an internal combustion engine (E), but which could also be implemented as an electric machine or other suitable device for generating output torque. For consistency of illustration, torque-generative device 12 will be described below as engine 12 , without limiting the scope to such a design.

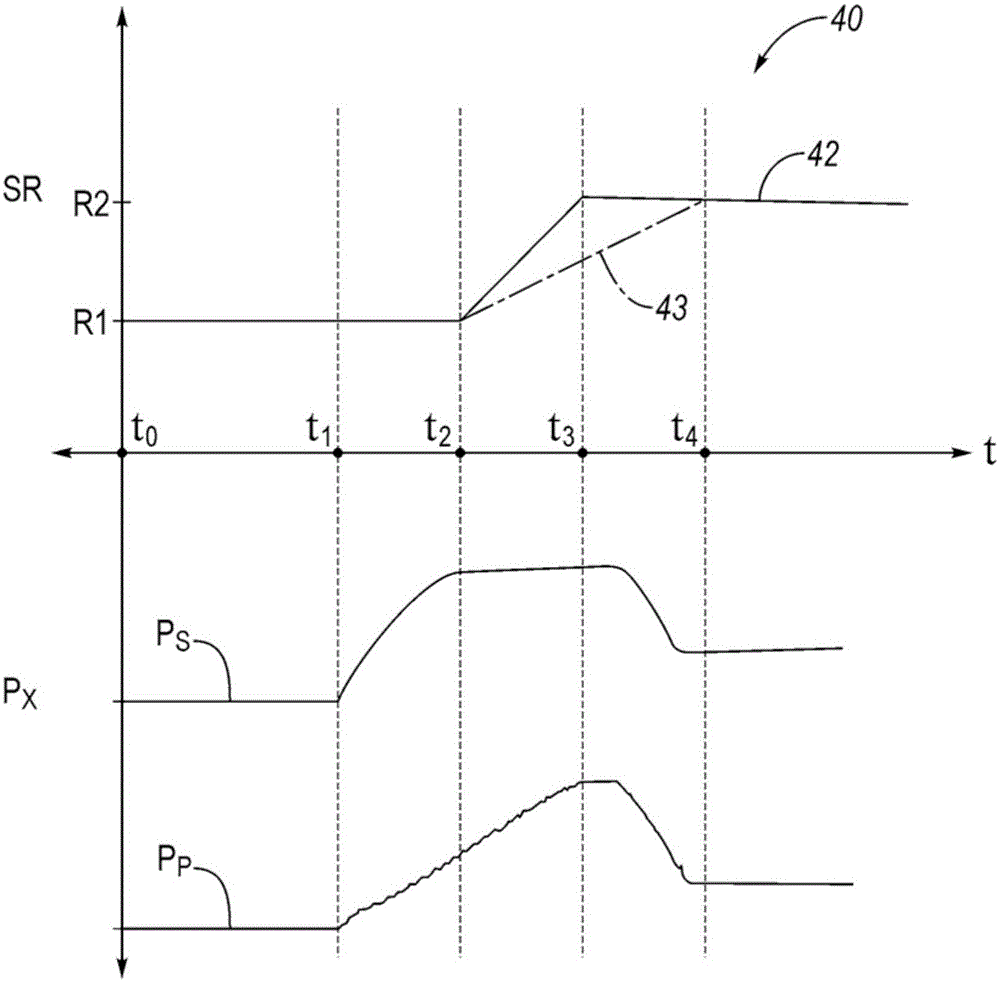

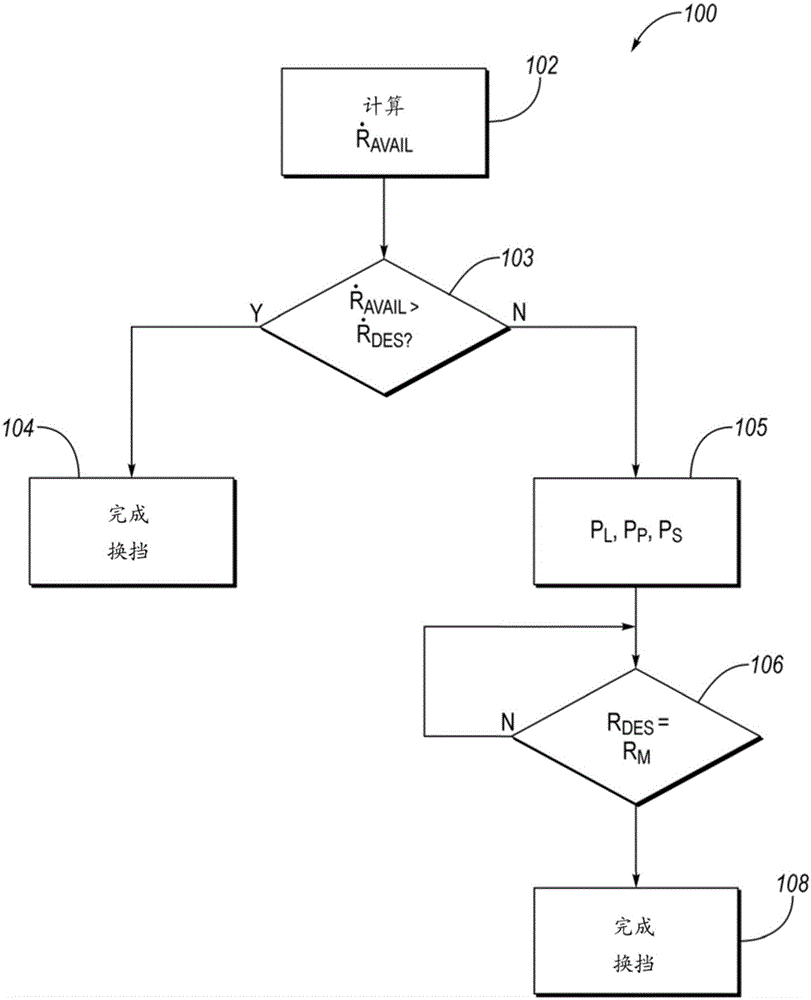

[0031] The vehicle 10 also includes a continuously variable transmission (CVT) 14 and a controller (C) 50 . see below figure 2 and 3 Described in further detail, the controller 50 is programmed to actively increase or stage the pressure level to the CVT 14 prior to an upcoming speed ratio change or gear shift of the CVT 14 to a desired speed ratio, and is performed in accordance with the method 100 of. The benefit of method 100 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com