A Sampling System Capable of Realizing Constant Flow and Equal Speed Sampling

A sampling system and constant flow technology, applied in the field of sampling technology, can solve the problems of frequent replacement, failure to realize constant speed sampling, fluctuating flue gas flow, etc., and achieve the effect of reducing sampling error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

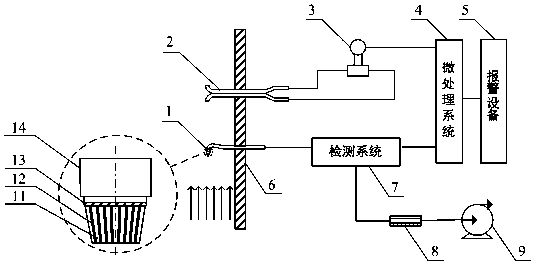

[0036] Such as Figure 1 As shown in the invention, a sampling system capable of realizing constant flow and constant speed sampling includes a sampling detection device, a speed measuring device, a micro-processing system and an alarm device. The sampling and testing device is composed of a new sampling nozzle 1 , a testing system 7 , a dryer 8 and a constant flow pump 9 . The novel sampling nozzle 1, the detection system 7, the dryer 8, and the constant flow pump 9 are sequentially connected through pipelines. The exhaust gas is sucked by the constant flow pump 9, and the flue gas is driven into the sampling nozzle 1, the detection system 7, and the dryer 8 in sequence, and the detected gas is dried and then discharged. The detection system 7 uses a detector based on the principle of light scattering, which can detect particulate matter in the sampled gas. The dryer 8 can dry the detected gas to prevent the constant flow pump 9 from being damaged due to excessive humidity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com