Speed-adjustable sampling device for static pressure balance method

A technology of static pressure balance and sampling device, which is applied in the direction of sampling device, climate sustainability, human health protection, etc. It can solve the problems affecting the service life of the device, the error of smoke and dust measurement, and high maintenance efficiency, so as to improve the service life and reduce detection Error, the effect of avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

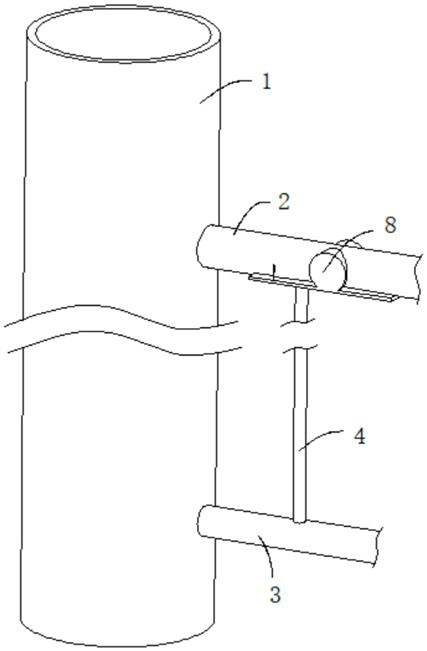

[0036] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 11 , a speed-adjustable sampling device of static pressure balance method, including a flue 1 and a sampling pipe 2 arranged in the flue 1, the end of the sampling pipe 2 away from the flue 1 is connected with a flue gas detection system, and the A smoke exhaust pipe 3 is connected to the bottom end, an L-shaped branch pipe 4 is arranged on the smoke exhaust pipe 3, and one end of the L-shaped branch pipe 4 away from the smoke exhaust pipe 3 is arranged in the sampling pipe 2, and a scraper ring 5 is arranged in the sampling pipe 2. The scraper ring 5 is provided with a disengagement component. The scraper ring 5 is movable against the inner wall of the sampling pipe 2 and the outer wall of the L-shaped branch pipe 4. The sampling pipe 2 is provided with a drive mechanism for driving the displacement of the scraper ring 5. A crushing mechanism for crushing lump dust is connected, and the c...

Embodiment 2

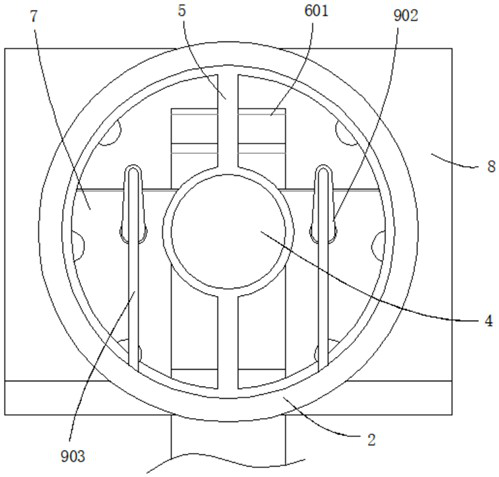

[0039] refer to image 3 , Figure 5 and Figure 7 , a speed-adjustable sampling device of a static pressure balance method, the same as that of Embodiment 1, and further, the scraping ring 5 includes a large ring 501 and a small ring 502, and one of the large ring 501 and the small ring 502 A connecting plate 503 is arranged between them, the large ring 501 is movable against the inner wall of the sampling tube 2 , and the small ring 502 is movable against the outer wall of the L-shaped branch pipe 4 .

[0040] Specifically, when the scraper ring 5 moves, it can scrape off the particles adhering to the inner wall of the sampling pipe 2 and the outer wall of the L-shaped branch pipe 4 at the same time, so that it can be easily absorbed by the smoke detection system and ensure the concentration of particles in the smoke. Test results.

Embodiment 3

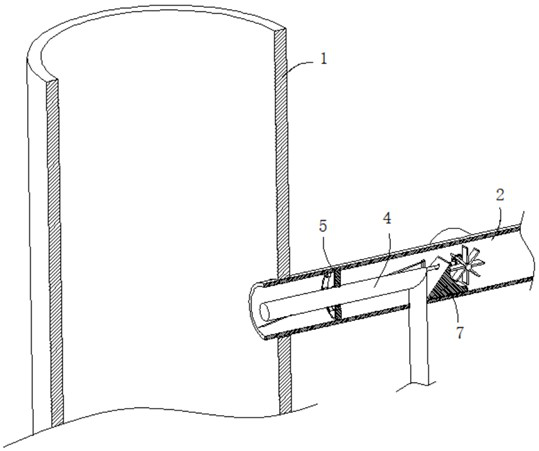

[0042] refer to figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 9 and Figure 10 , a speed-adjustable sampling device of a static pressure balance method, the same as in Embodiment 2, further, the drive mechanism includes a rotating rod 6 that is rotatably connected in the sampling pipe 2, and the outer wall of the rotating rod 6 is connected with a rotating blade 601, The sampling pipe 2 is also provided with a guide block 7 for guiding the moving direction of the flue gas, the outer wall of the sampling pipe 2 is provided with a casing 8, the inner wall of the casing 8 is rotatably connected with a half gear 801, and the half gear 801 is fixedly connected with the rotating rod 6, A rack plate 802 is slidably connected to the inner wall of the housing 8, and the rack plate 802 is meshed with the half gear 801. A first elastic element 803 is arranged between the rack plate 802 and the inner wall of the housing 8, and a pull rope 804 is connected to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com