Dry dust removal industrial vacuum cleaner

An industrial vacuum cleaner and dry dust removal technology, applied in the direction of vacuum cleaners, suction filters, cleaning equipment, etc., can solve the problems of reduced dust removal efficiency, complex structure, and easy clogging of the filter screen by dust. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

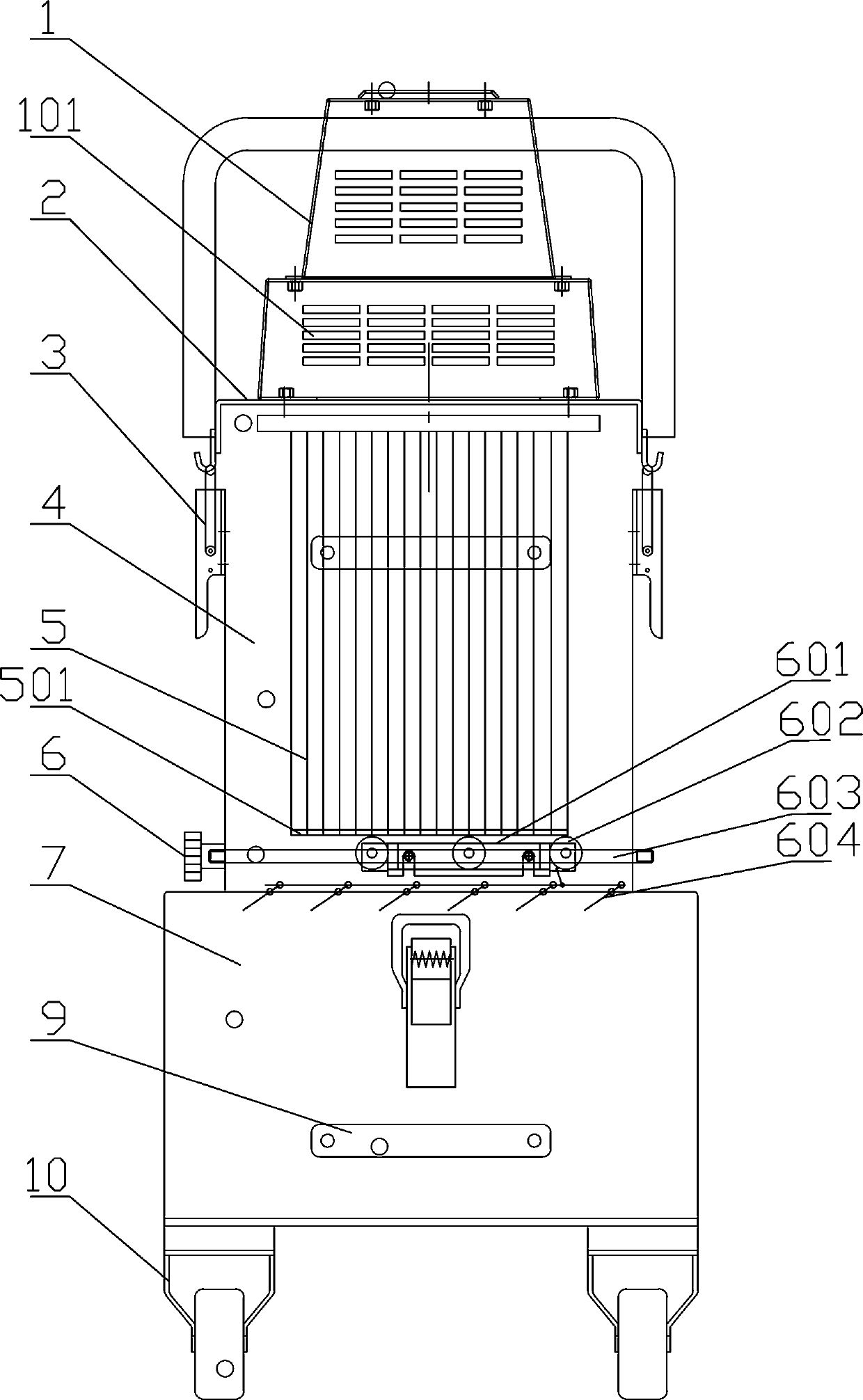

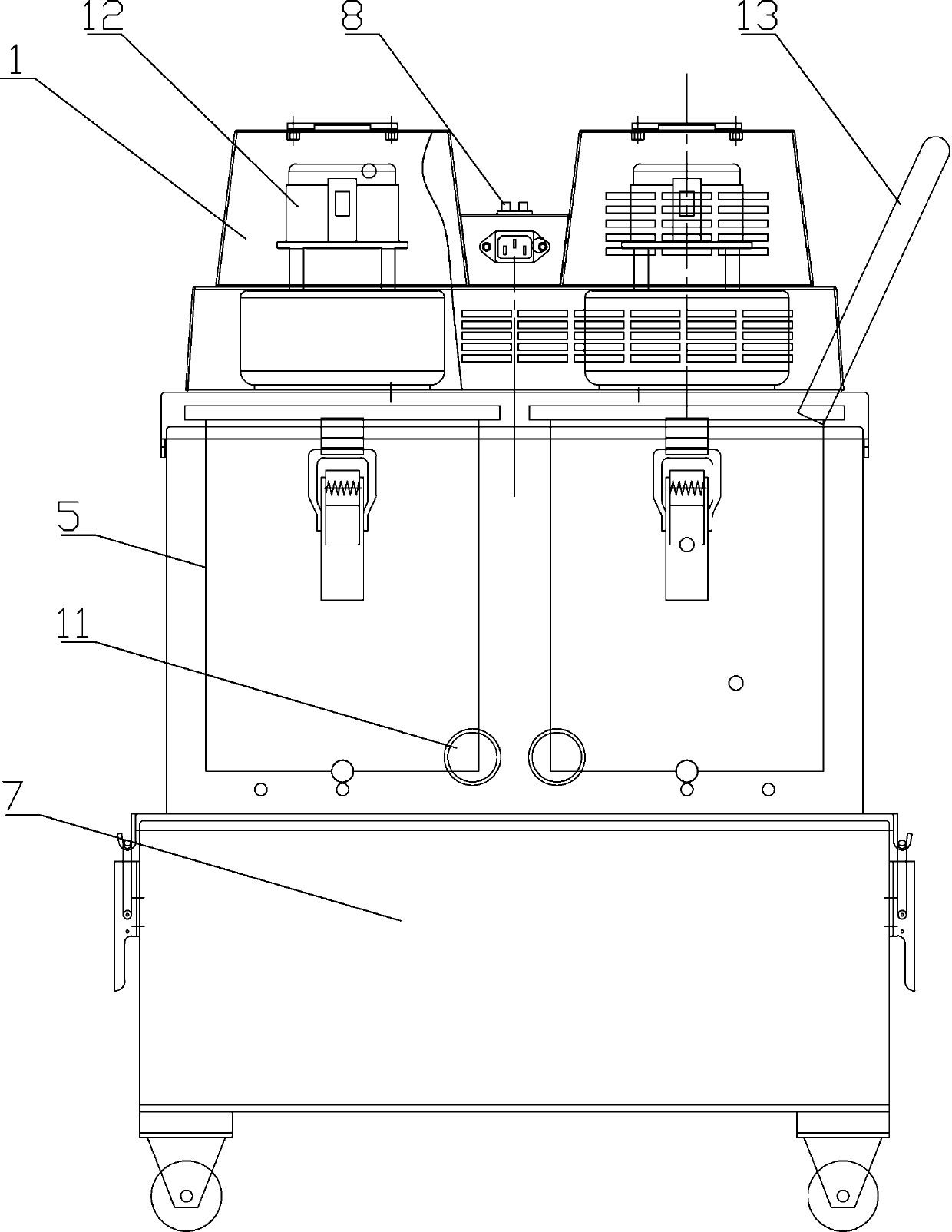

[0018] Such as figure 1 , 2 Among them, a dry-type dedusting industrial vacuum cleaner includes a filter box 4, a filter screen 5 is arranged inside the filter box 4, a fan 12 is arranged on the top of the filter box 4, a dust collection box 7 is arranged at the bottom of the filter box 4, and a filter screen 5 is provided inside The cavity communicates with the air inlet of the blower fan 12, and a filter chamber is formed between the inner wall of the filter box 4 and the outer wall of the filter screen 5, the outer wall of the filter box 4 is provided with an air inlet 11, and the bottom of the filter screen 5 is provided with an ash removal device 6 to remove dust The device 6 is provided with a support 601 which is in contact with the filter screen 5 , and a vibrator 602 is provided on the support 601 . After dust removal for a period of time, start the vibrator 602, and by driving the filter screen 5 to vibrate, the dust on the filter screen 5 is shaken off into the dus...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap