Waterproof coating production device

A production device and coating technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of single production products, no material heating system, poor control of precision adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0023] The present invention will be further described below in conjunction with specific embodiments.

Embodiment approach

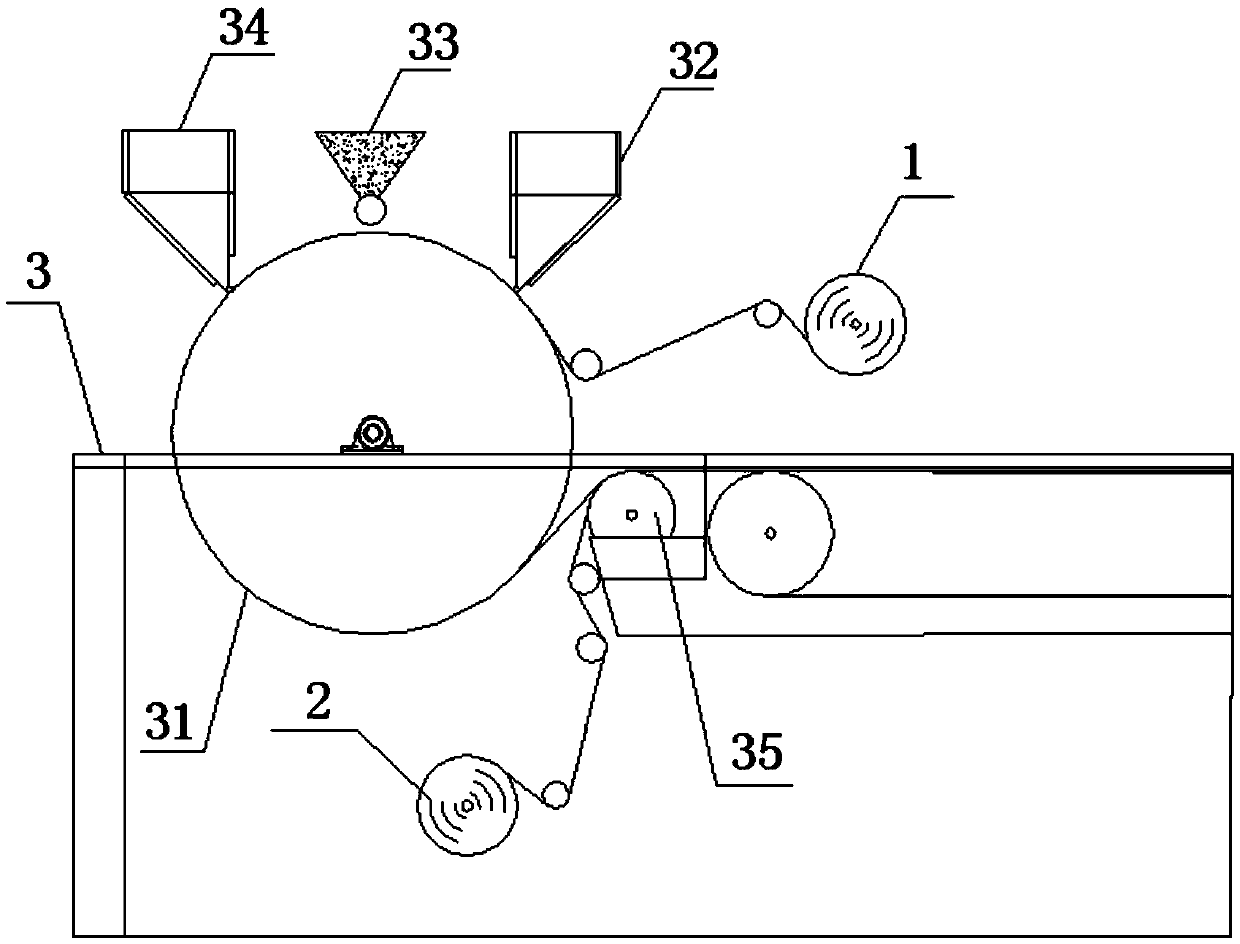

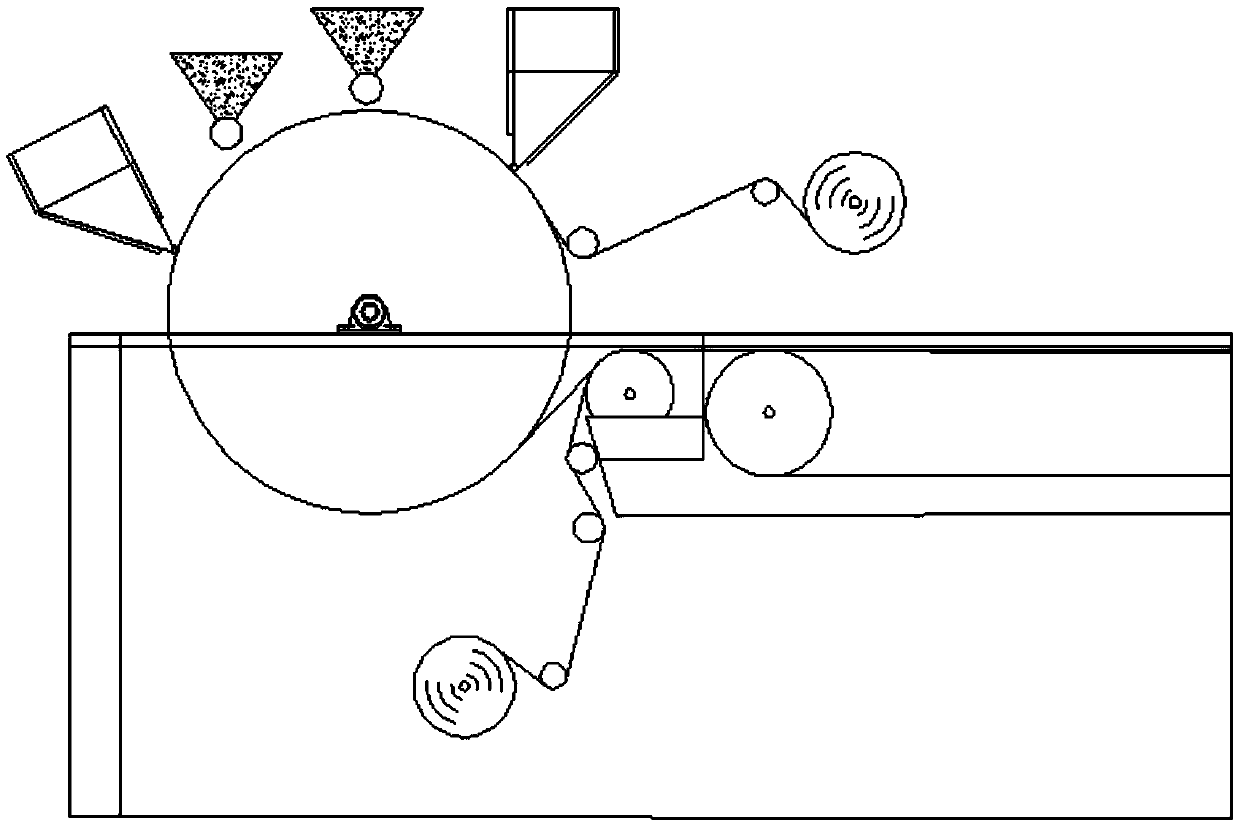

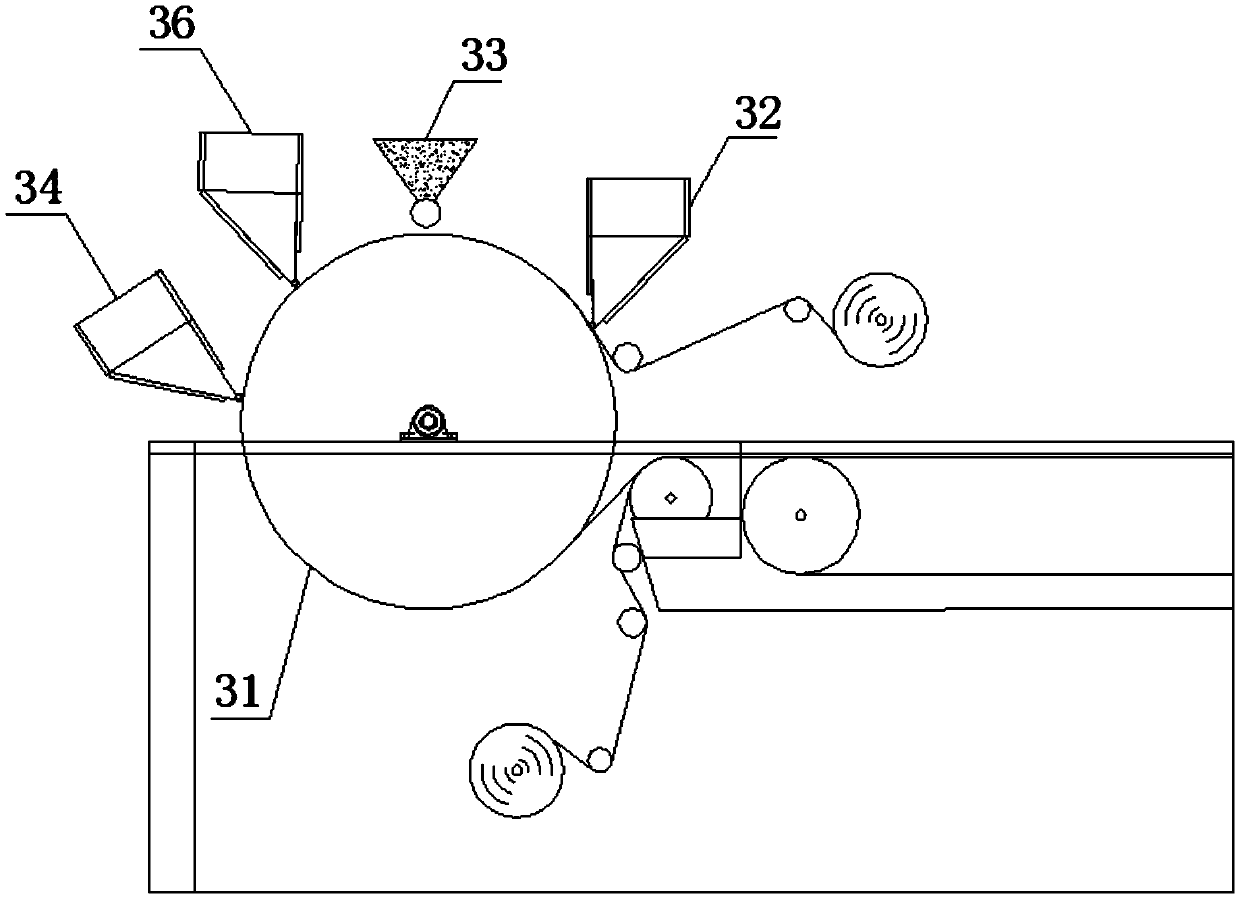

[0024] combine figure 1 , an embodiment of the present invention. A waterproof coating production device, comprising:

[0025] A waterproof coating production device, comprising: a first output assembly 1, used to output the first film; a molding assembly 3 arranged together with the first output assembly; the molding assembly includes: a roller 31, used to drive The first film moves; the first coating mechanism 32 is used for coating the first film on the roller. In this implementation, this structure can continue to coat the single-layer film for coating production. The roller is used as a workbench to ensure continuous production and facilitate the coating of the first film unfolded on the roller. At the same time The relative area of the roller is large, which reduces the heat dissipation time.

[0026] In order to speed up the heat dissipation of the roller, a water cooling mechanism is provided inside the roller for cooling the roller. In this embodiment, in order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com