Pipe bending device in pipe bending machine

A technology of a pipe bending device and a pipe bending machine, which is applied in the directions of feeding devices, positioning devices, storage devices, etc., can solve the problems of injury to workers' pipe bending arms, hidden dangers in production safety, and limit the scope of application of pipe bending machines, so as to improve the performance of the pipe bending machine. Scope of application, the effect of improving the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

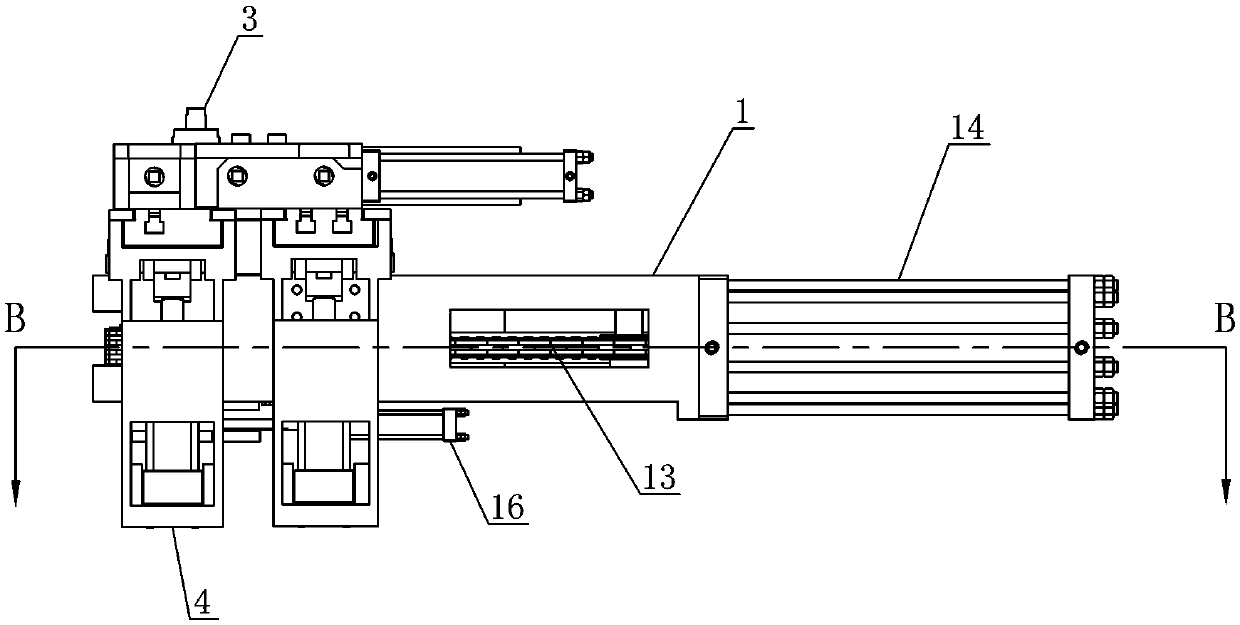

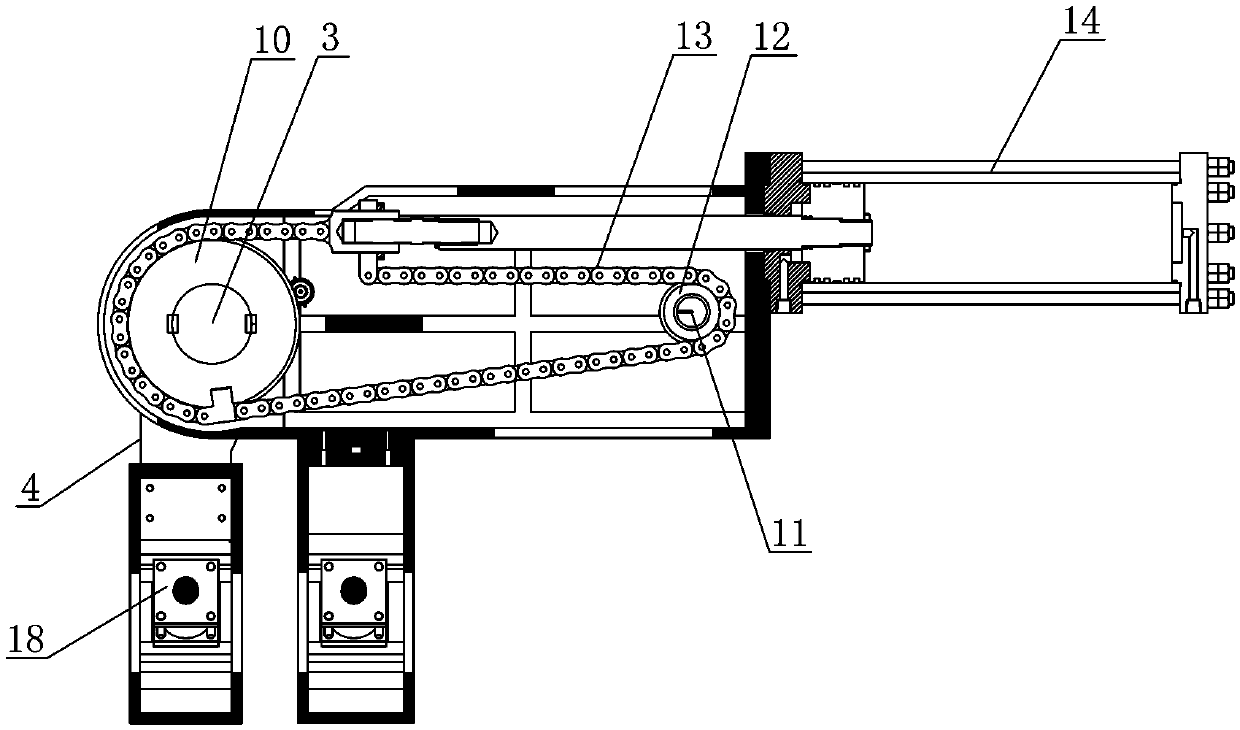

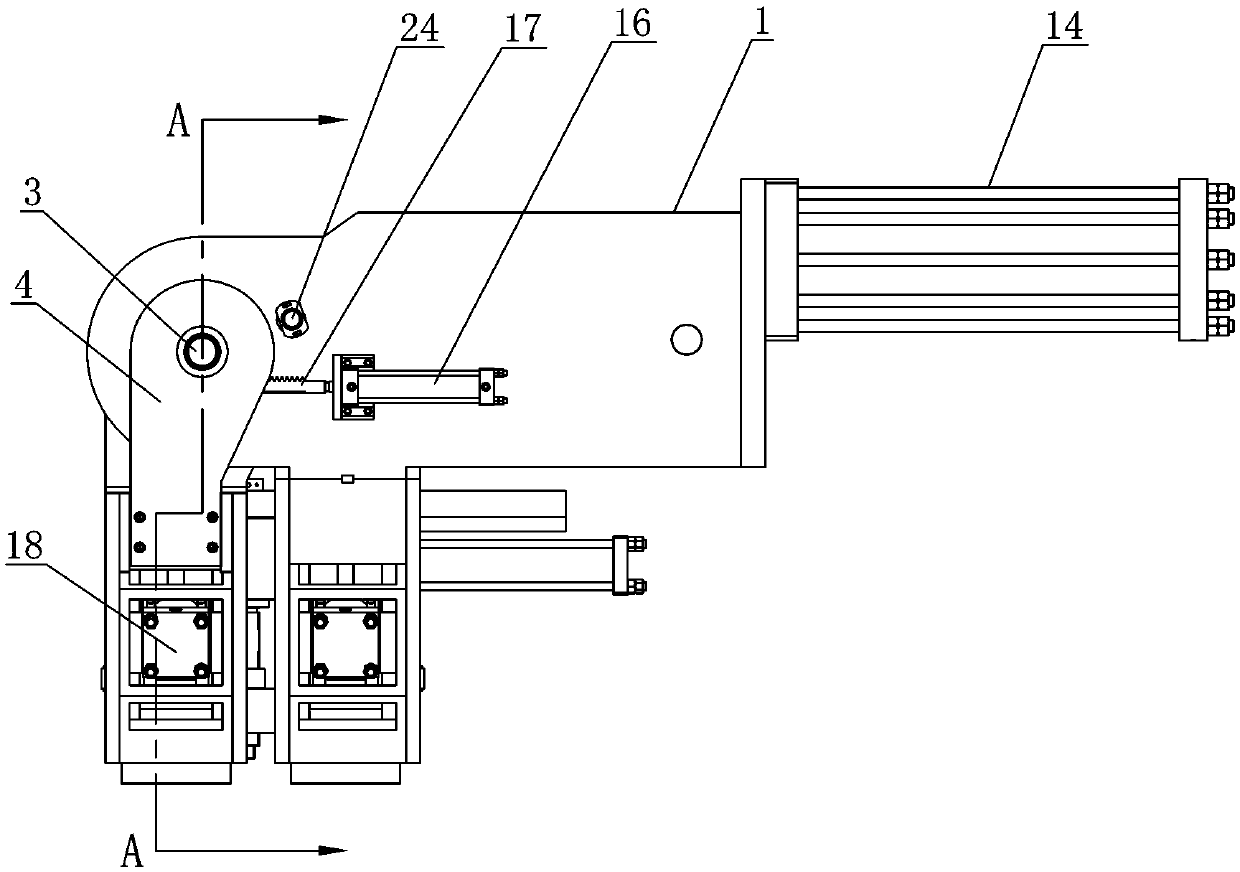

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the pipe bending device in the pipe bending machine includes: a frame 1, the front end of the frame 1 is movable and vertically supported with a main shaft 3 with a wheel mold 2 on the top, and the main shaft 3 is driven by the first driving mechanism Rotate, on the main shaft 3, the elbow arm 4 is movably sleeved, and the elbow arm 4 can rotate relative to the main shaft 3 under the drive of the second drive mechanism. A slider 6 is slidably arranged, and the slider 6 moves along the horizontal guide rail 5 under the drive of the third driving mechanism. And the outer end of the slide block opposite to the main shaft 3 is provided with a key 8, and a positioning disc 9 is fixedly set on the main shaft 3, and a keyway for inserting the key 8 is provided on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com