Rapid mold opening electric type injection mold of plastic gear

A technology for plastic gears and injection molds, applied in gears, household appliances, and other household appliances, etc., can solve the problems of affecting the service life of gears, hollowing, and affecting the image of corporate products, so as to improve the pass rate, speed up, and reduce hollowing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

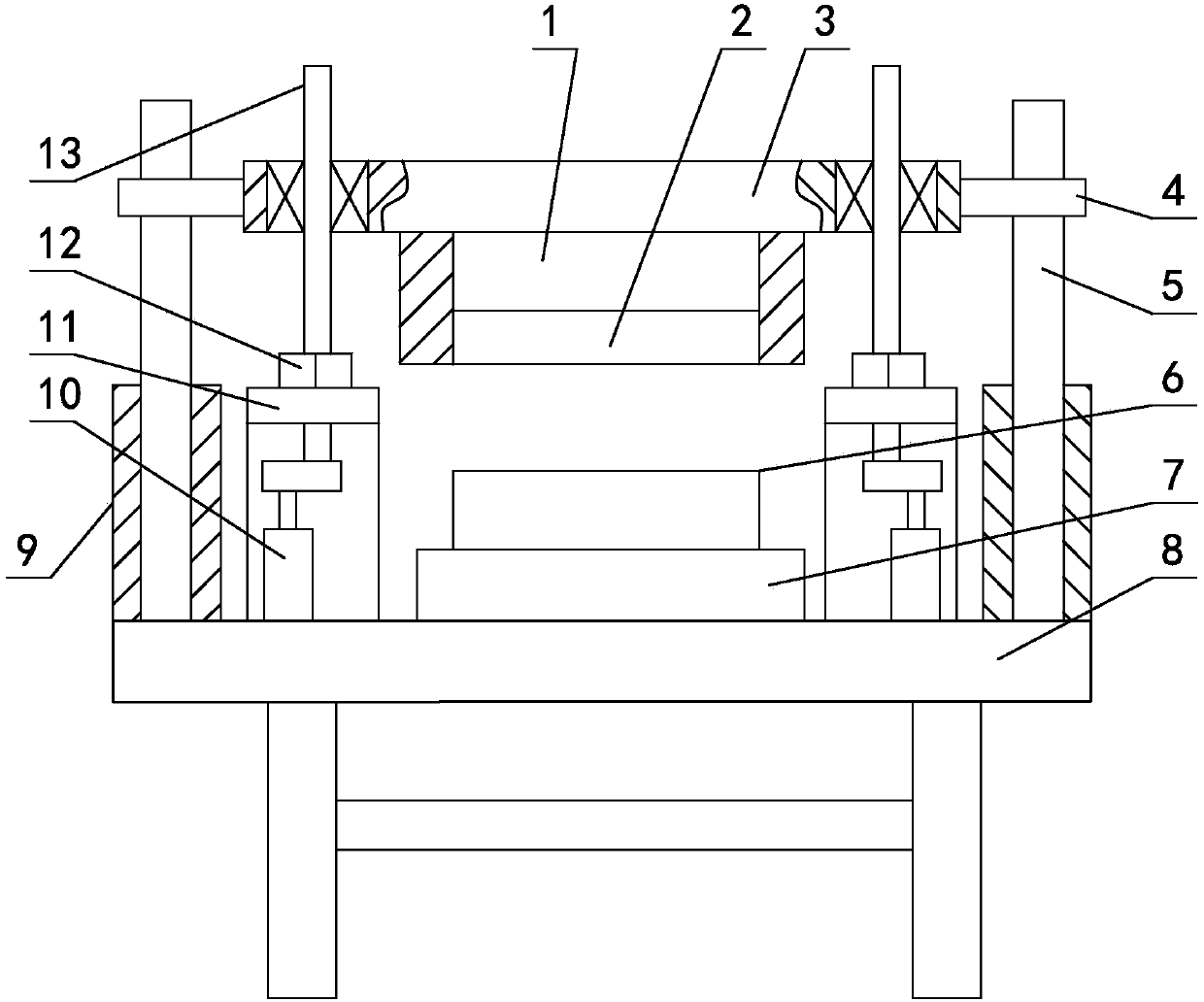

[0014] Such as figure 1 As shown, the quick-opening electric injection mold for plastic gears includes a workbench 8, an injection upper mold 1 and an injection lower mold 6 that cooperate with each other. The injection lower mold 6 is installed on the lower template 7, and the lower template 7 is installed on the workbench 8. On the top, the top of the injection molding upper mold 1 is installed on the upper template 3, and guide pillars 4 are vertically arranged on the workbench 8 on the left and right sides of the lower template 7, and guide sleeves 5 are set on the guide pillars 4, and the guide sleeves 5 respectively correspond to It is fixed on the upper template 3, and the outer periphery of the injection molding upper mold 1 is covered with a thermal insulation sleeve 2. The thermal insulation sleeve 2 is made of aluminum alloy material, and a rubber sleeve 9 for rapid mold opening is sleeved on the guide post 4. The height is 10mm higher than the height of the top sur...

Embodiment 2

[0018] On the basis of Embodiment 1, further changes are made, and the wall thickness of the thermal insulation cover 2 is 50 mm; The thickness becomes 30mm. Others are the same as embodiment one.

Embodiment 3

[0020] On the basis of Embodiment 1, further changes are made, the cover wall thickness of the thermal insulation cover 2 is 40mm; the top surface height of the rubber cover 9 is 20mm higher than the top surface height of the injection lower mold 6, and the cover wall of the rubber cover 9 The thickness becomes 25mm. Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com