Shelving strip-shaped material storage frame

A long type, storage rack technology, applied in storage devices, transportation and packaging, etc., can solve the problems of scattered goods, high work intensity, hidden safety hazards, etc., to reduce storage space, increase handling activity, and ensure The effect of cargo security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

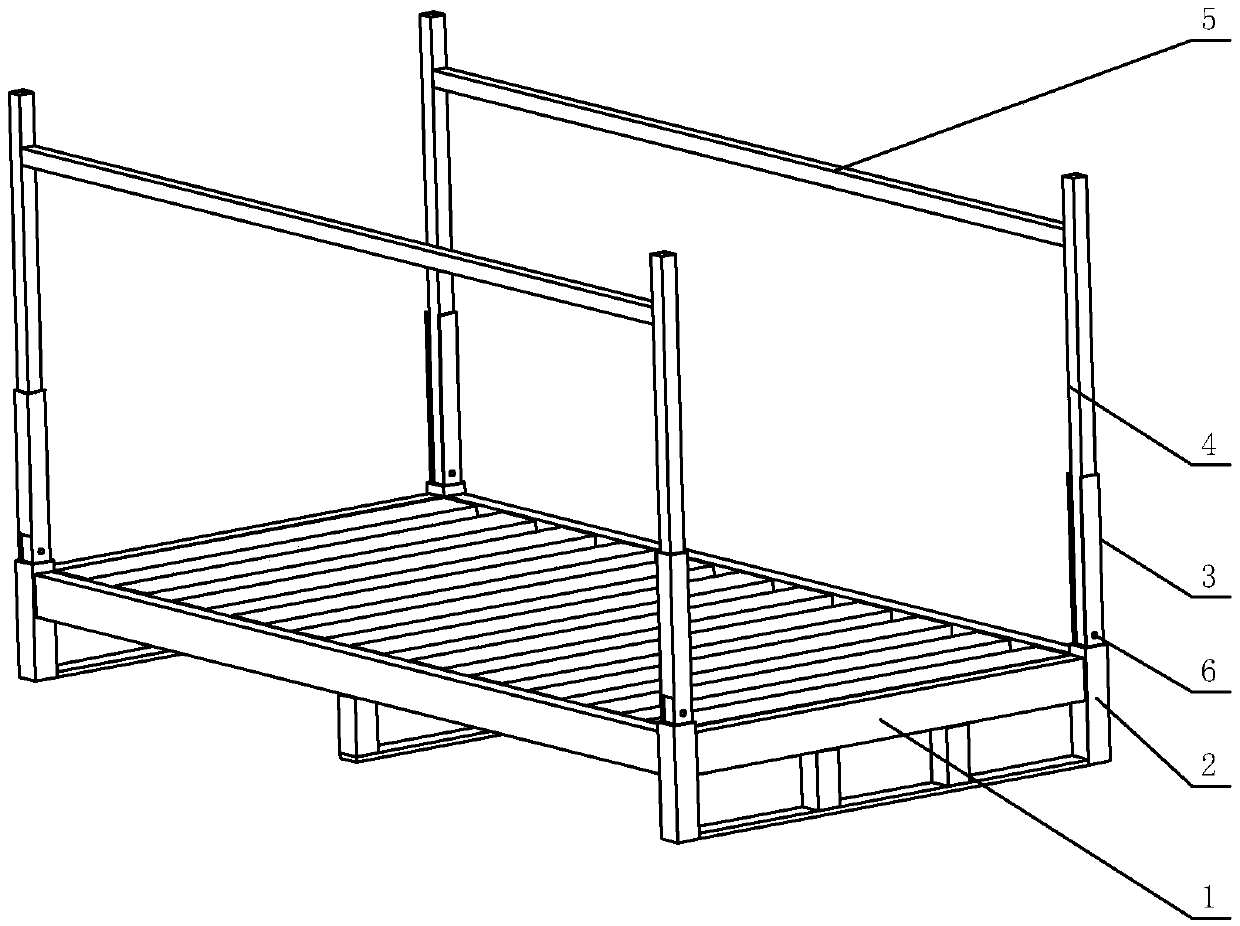

[0030] figure 1 Among them, the technical solution of the present invention provides a shelf-type elongated material storage rack, including a chassis, and the chassis is a standard chassis conforming to the "double-sided fork entry" mode, and its invention points are:

[0031] On the four corners of the chassis 1, a chassis square tube 2 is respectively arranged correspondingly;

[0032] An empty stacking column 3 is inserted into each of the square tubes of the chassis; a rotating shaft 6 is arranged on the empty stacking column, and the empty stacking column can be folded through the rotating shaft placed on the upper end face of the chassis.

[0033] A column 4 is plugged into each of the empty stacking columns;

[0034] A beam 5 is respectively arranged between the same-side uprights on two opposite sides of the chassis;

[0035] The storage ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com