Outdoor jacquard velvet and weaving method thereof

A velvet and open field technology, applied in the field of textile fabrics, can solve problems such as high raw material costs, acid and alkali pollution of the environment, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0113] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0114] An open field jacquard velvet comprises a velvet base cloth J, and a velvet flower area K is arranged on the velvet base cloth J 1 and velvet dew area K 2 , its weaving method is as follows:

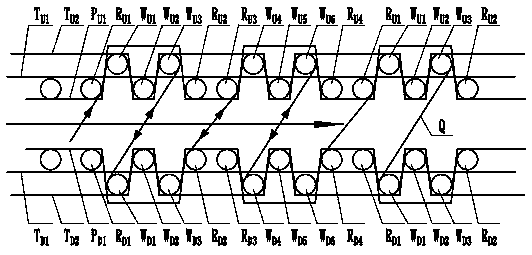

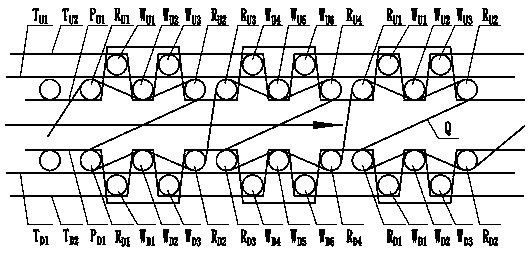

[0115] In the first step, the first warp yarn T of the upper base fabric U1 , The first warp yarn T of the base fabric of the lower layer D1 Wrapped on a weaving beam as a tight warp yarn; the second warp yarn T of the upper base fabric U2 , The second warp yarn T of the lower base fabric D2 , Upper auxiliary warp P U1 , the lower auxiliary warp P D1 It is wound on another weaving beam and is defined as a loose warp yarn; the velvet warp yarn Q is wound on the third weaving beam.

[0116] The second step: string ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com