Eight-in eight-out optical cable splice box

An optical cable splice box and box body technology, used in optics, light guides, optical components, etc., can solve the problems of limited number of optical fibers in and out of the fusion splice inventory, and poor structural design of optical cables in and out, so as to achieve good temperature cycle effect and beautiful appearance. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

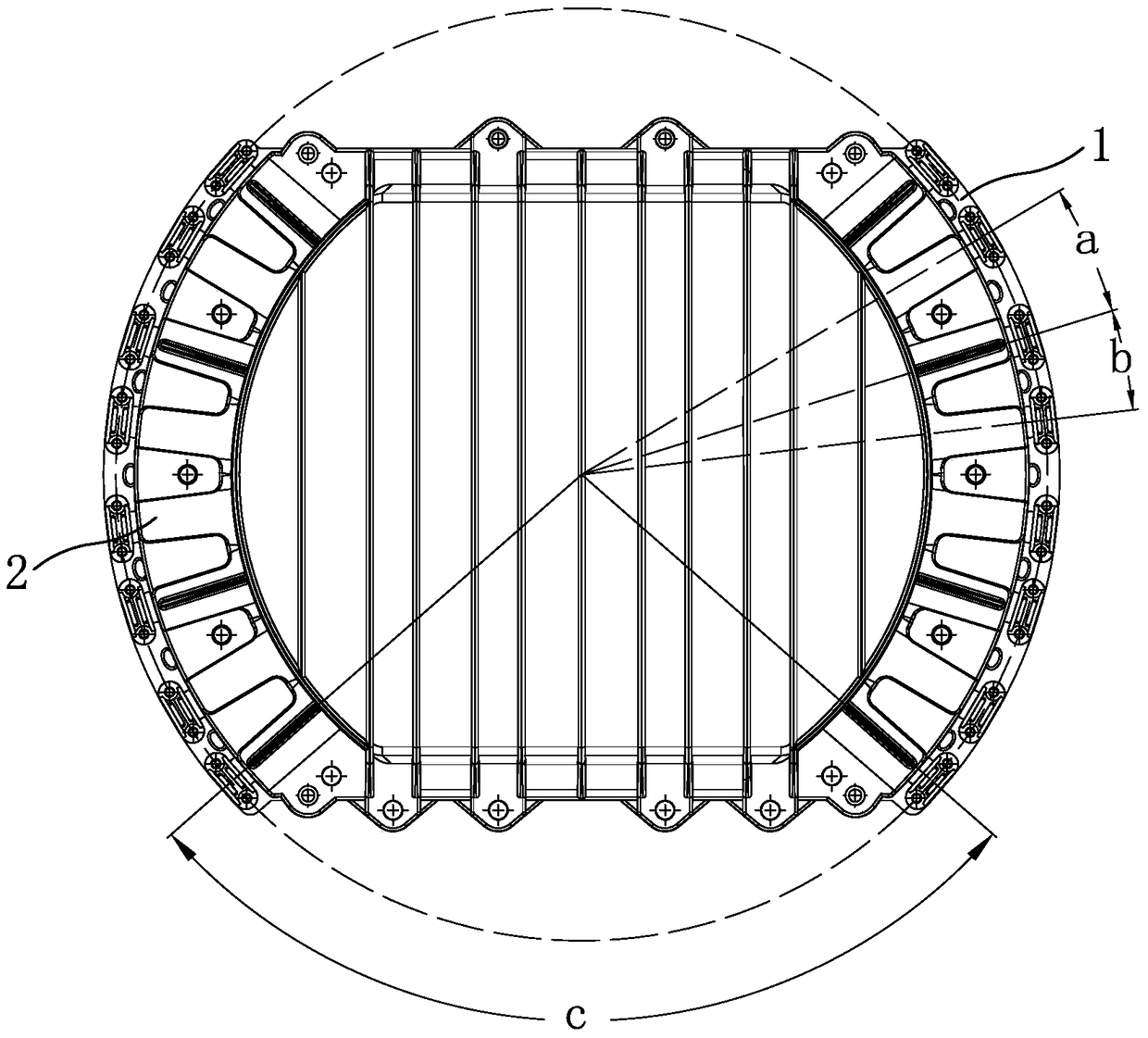

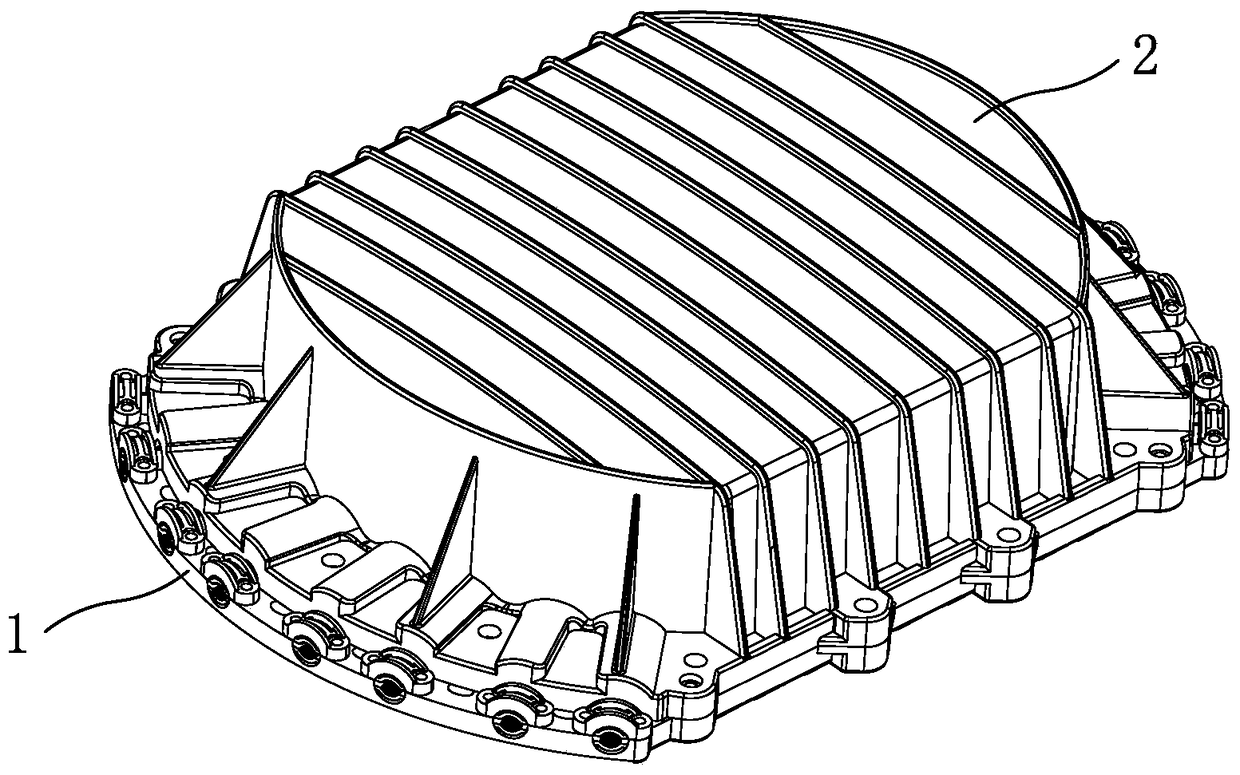

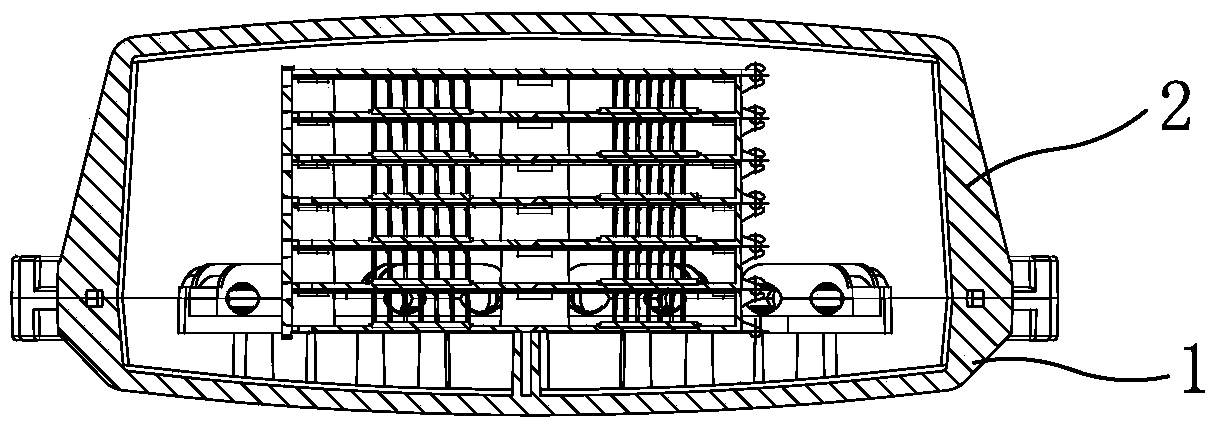

[0023] Now in conjunction with the accompanying drawings, the structure and use of the present invention will be further described. Such as Figure 1-Figure 7 As shown, the optical cable splice box includes a box body 1, a box cover 2, and a fusion splice tray 5. The edge of the notch of the inner diameter of the box is provided with a raised ring rib, and the ring rib of the box body is connected with the ring groove buckle of the box cover. Closed, the box cover and the box body are connected by screws to form a shell, the buckle is provided with sealing putty, and the outer diameter of the box cover is provided with triangular reinforcing ribs. The above housing is circular, the angle c between the two ends of the straight sides of the housing is 95 degrees, and the angle a between the inlet and outlet holes of the two housings is 10 degrees. The angle b between the inlet hole and the outlet hole between a group is 15 degrees. The two sides of the shell are symmetrically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com