Soft object dicing machine

A cutting machine and article technology, applied in the direction of metal processing, etc., can solve the problems of reducing work efficiency, impact, and low cutting efficiency, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

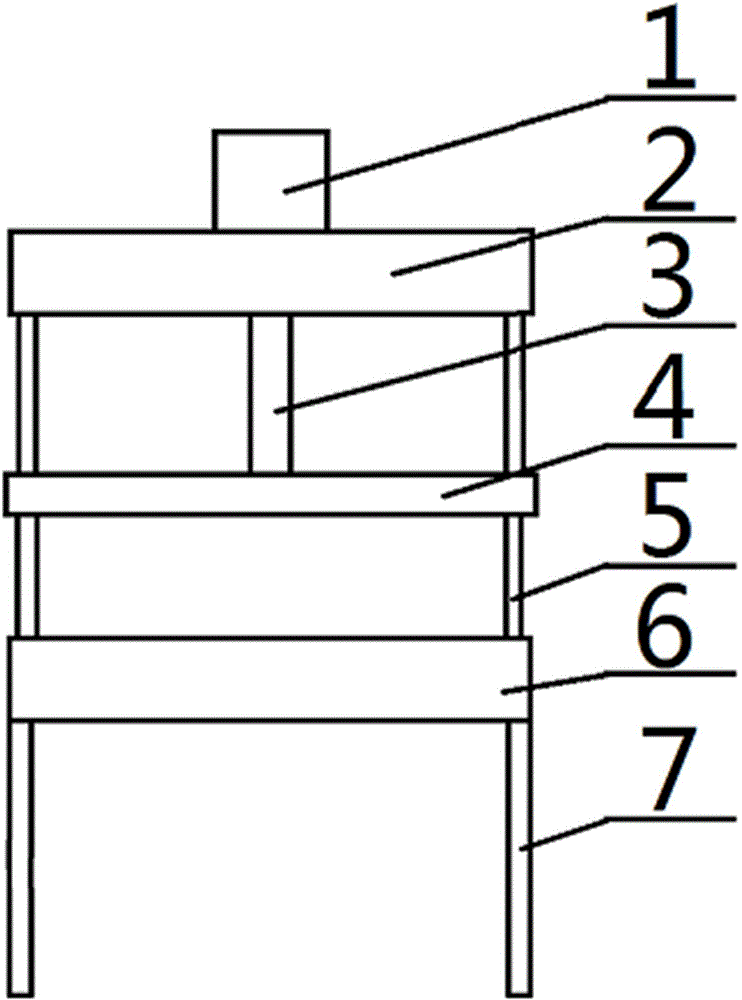

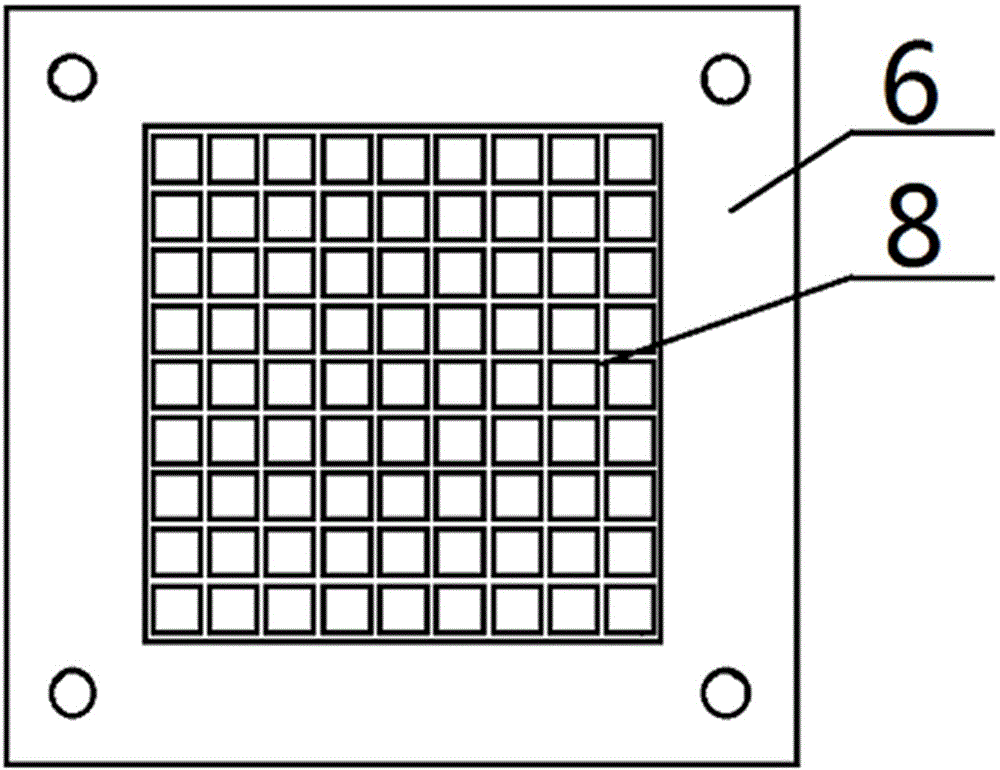

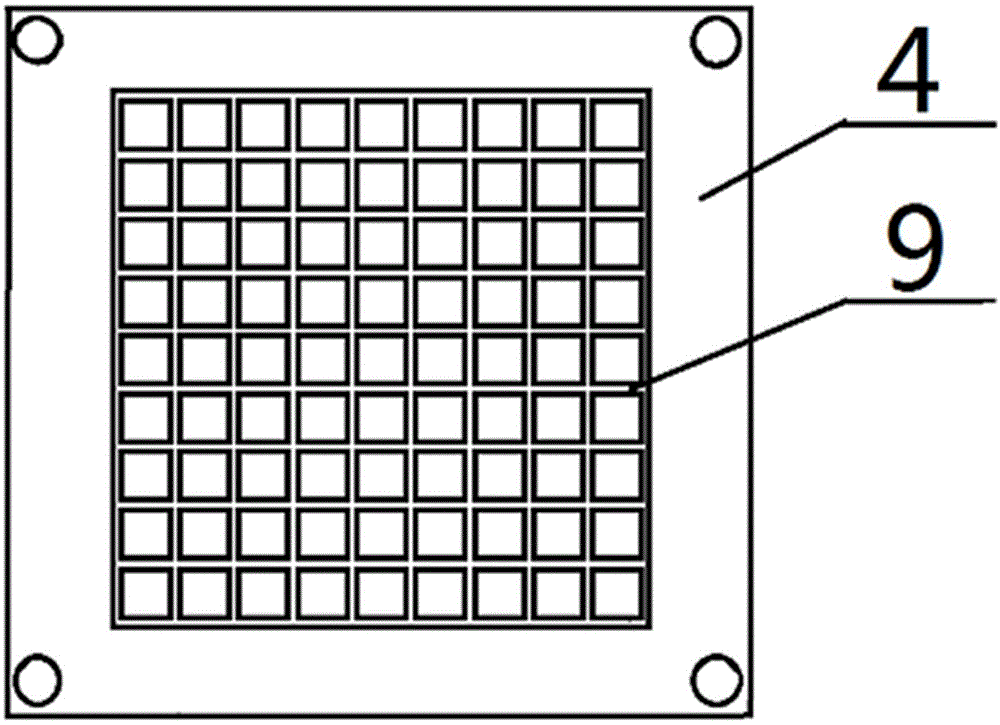

[0016] Referring to the accompanying drawings, a cutting machine for soft goods includes a cylinder 1, a top plate 2, a piston rod 3, a movable knife plate 4, a guide column 5, a square panel 6, a frame 7, a groove 8, and a cutter 9; The square panel 6 is horizontally arranged and installed on the frame 7, and a guide column 5 is respectively installed at the four corners above the square panel 6; the movable blade 4 is horizontally arranged above the square panel 6, and the four corners of the movable blade 4 The circular through-holes are matched with the four guide columns 5; a top plate 2 is fixed on the top of the four guide columns 5, and a cylinder 1 is installed at the center of the top plate 2, and the piston rod 3 at the lower end of the cylinder 1 passes through the top plate 2 to connect the mobile The center position of the knife plate 4; a groove 8 is arranged on the square panel 6, and the vertical and horizontal small grooves in the groove 8 form a grid structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com