Bend single-core cable connector

A single-core cable and connector technology, which is applied to vehicle connectors, connections, and components of connecting devices, etc., can solve the problems of poor sealing, easy water entry, and poor waterproof performance of cable connectors, and achieves improved waterproof performance. Easy wiring, quick and easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

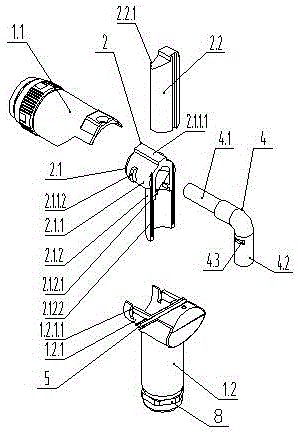

[0022] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

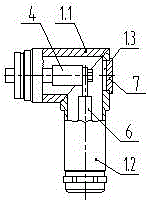

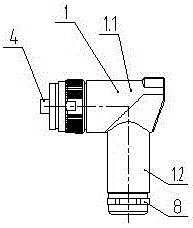

[0023] attached figure 1 The prior art cable connector for electric vehicles shown includes an outer shell 1, an inner core 4, and a terminal 6. The outer shell 1 is a right-angled member assembled from a flat outer shell 1.1 and a vertical outer shell 1.2. The horizontal outer shell 1.1, The vertical casing 1.2 is joined at right angles by inclined joining surfaces. The gland head 8 is fixedly connected to the lower end of the vertical jacket 1.2. The inner core 4 is a straight rod-shaped member, which is installed in the inner hole of the flat outer casing 1.1, and the terminal 6 extends from the inner hole of the vertical outer casing 1.2, and is connected to the end of the inner core 4 by threads, and the inner core 4 and the connecting terminal 6 are in the Connect in the inner hole of the junction of the flat outer jacket 1.1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com