Non-stop gas online drilling device and method

An installation method and a technology for connecting flanges, which are applied in the direction of branch pipelines, pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of casualties, property, production stoppage, loss, etc., and achieve good safety results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] A non-stop online hole opening device according to an embodiment of the present invention, the online hole opening device includes:

[0043] Welding flange, one end of the welding flange is suitable for welding on the pipeline;

[0044] a first valve, one end of the first valve is fixed on the other end of the welding flange;

[0045] The opening part, the opening part is installed on the other end of the first valve, and is kept sealed with the first valve; the drill bit of the opening part is suitable for passing through the first valve, welding flange.

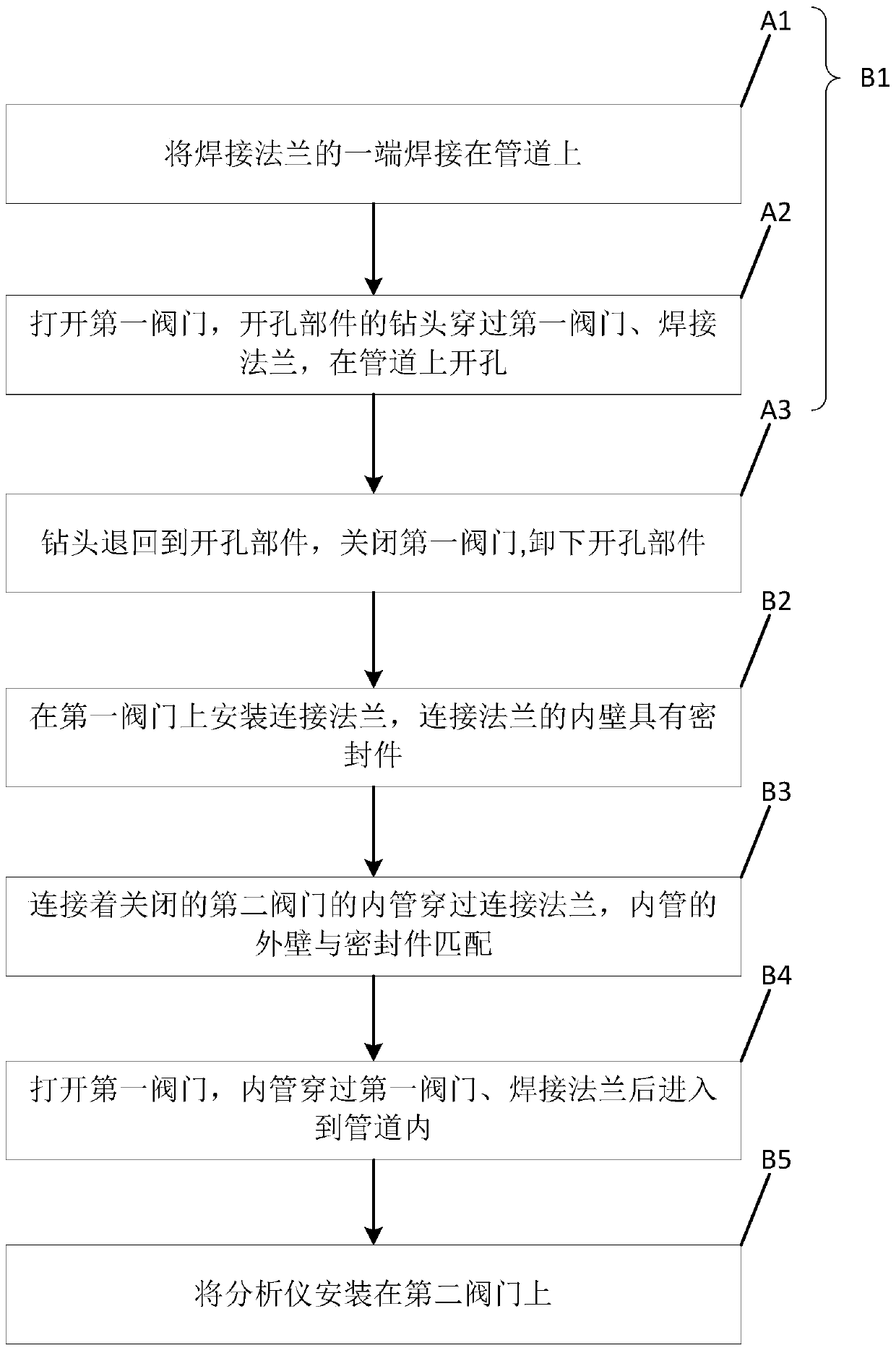

[0046] figure 1 Schematically shows the flow chart of the non-stop gas online drilling method of the embodiment of the present invention, as figure 1 As shown, the on-line hole opening method comprises the following steps:

[0047] (A1) Weld one end of the welding flange to the pipe;

[0048] The opening part is installed on the other end of the welding flange through the first valve, and is kept sealed with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com