Offshore jacket ice breaking structure with vacuum cavities

A technology for jackets and vacuum chambers, applied in underwater structures, infrastructure engineering, water conservancy projects, etc., can solve problems such as damage to jacket rods, achieve emission reduction commitments, speed up marketization and commercialization, and avoid The effect of grout failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

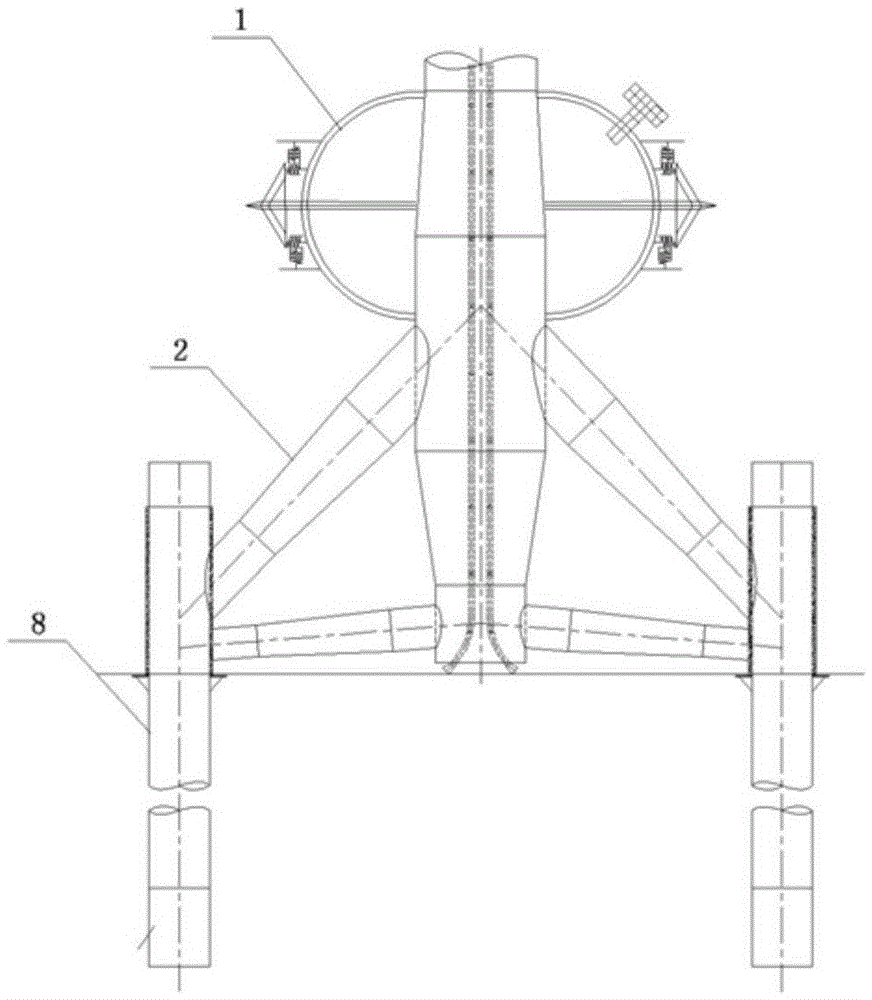

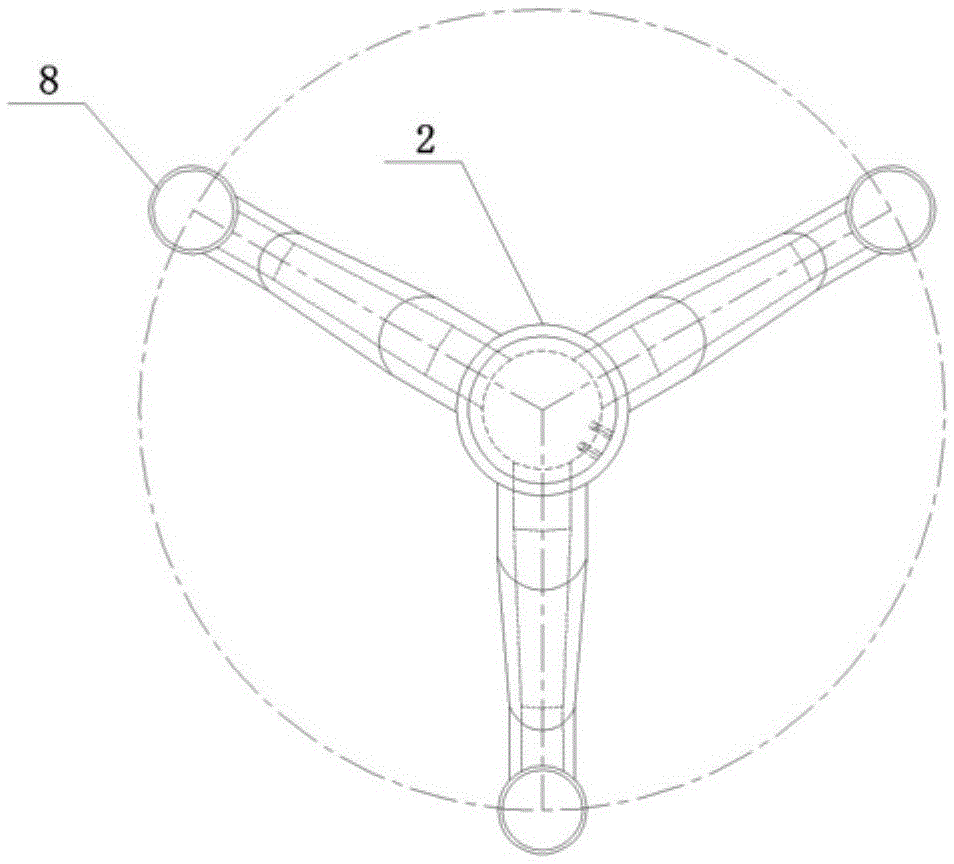

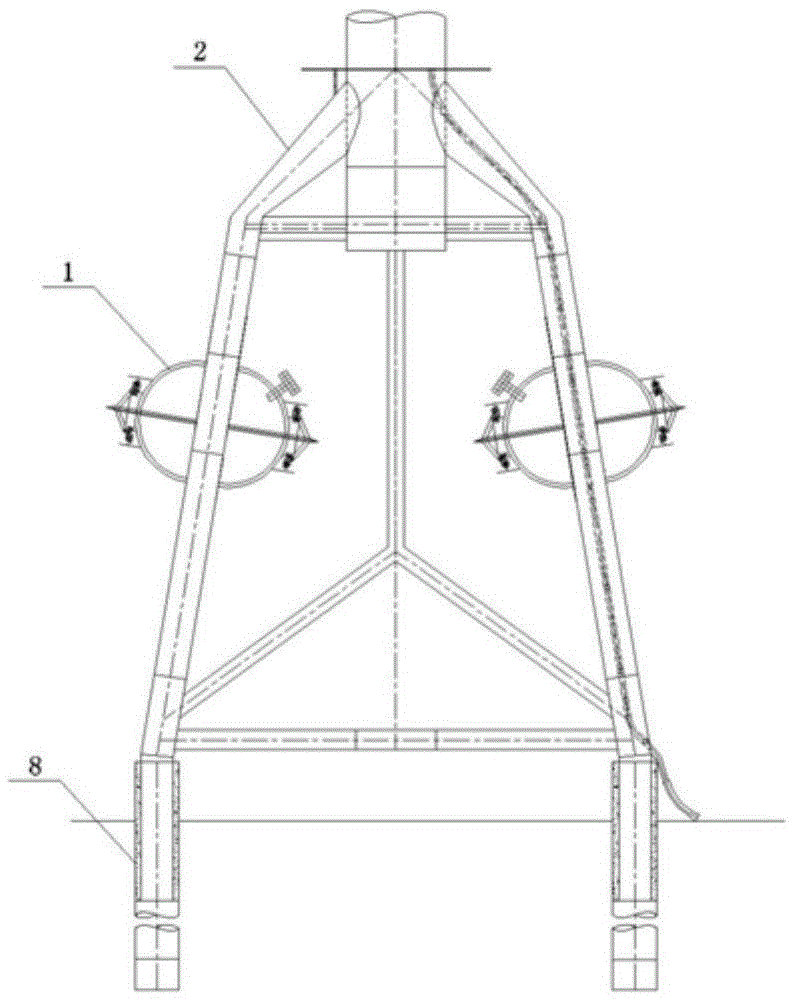

[0037] A jacket ice-breaking structure with a vacuum cavity: such as Figure 7 As shown, it includes ice-breaking element 1, jacket rod 2, and steel pipe pile 8. The outer side of jacket rod 2 is covered with ice-breaking element 1. Ice-breaking element 1 and jacket rod 2 are connected by welding. Jacket rod 2 and The steel pipe piles 8 are connected by grouting or welding. The upper part of the steel pipe pile 8 structure is the jacket rod 2, and the lower part goes deep into the seabed. The whole structure is supported by the steel pipe pile 8 foundation and fixed at sea.

[0038] Such as Figure 8-12 As shown, the ice breaking element 1 includes a cone ring 3, a ball plate 4, a round rod 5, a spring 6, a vacuum valve 7 and a cylinder 9, and the cylinder 9, the ball plate 4 and the round rod 5 are all made of stainless steel alloy materials, and the outer Coated with epoxy resin type heavy-duty anti-corrosion coating. The cone ring 3, the spring 6, and the vacuum valve 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com