Up-moving block type booster clamping mechanism

An upper-moving block-type and mold-locking technology is applied to the field of the upper-moving block-type pressurized mold-locking mechanism, which can solve the problems of difficult processing operations, high work intensity, and eccentric center of gravity, and achieves compact structure and convenient operation. , the effect of easy mode adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

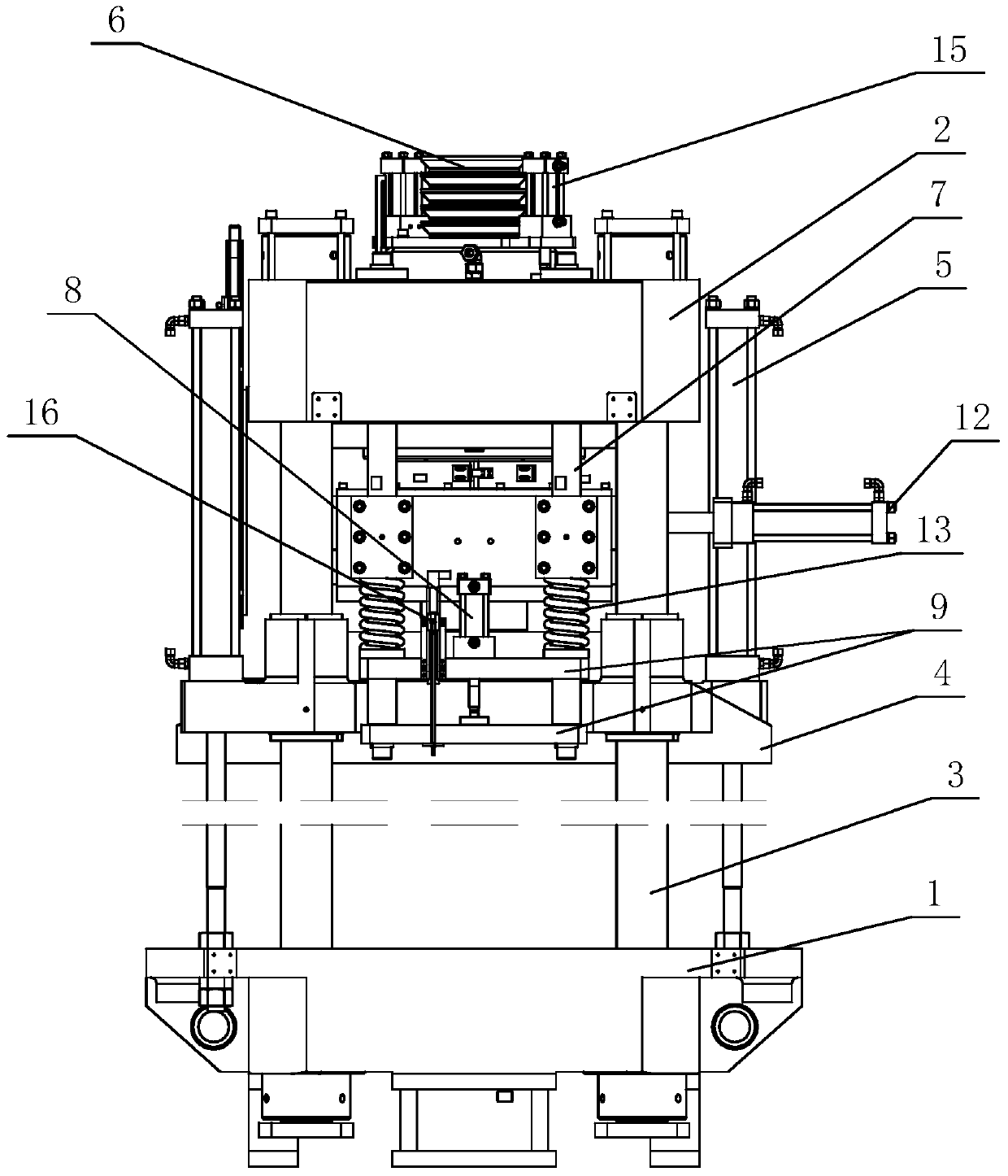

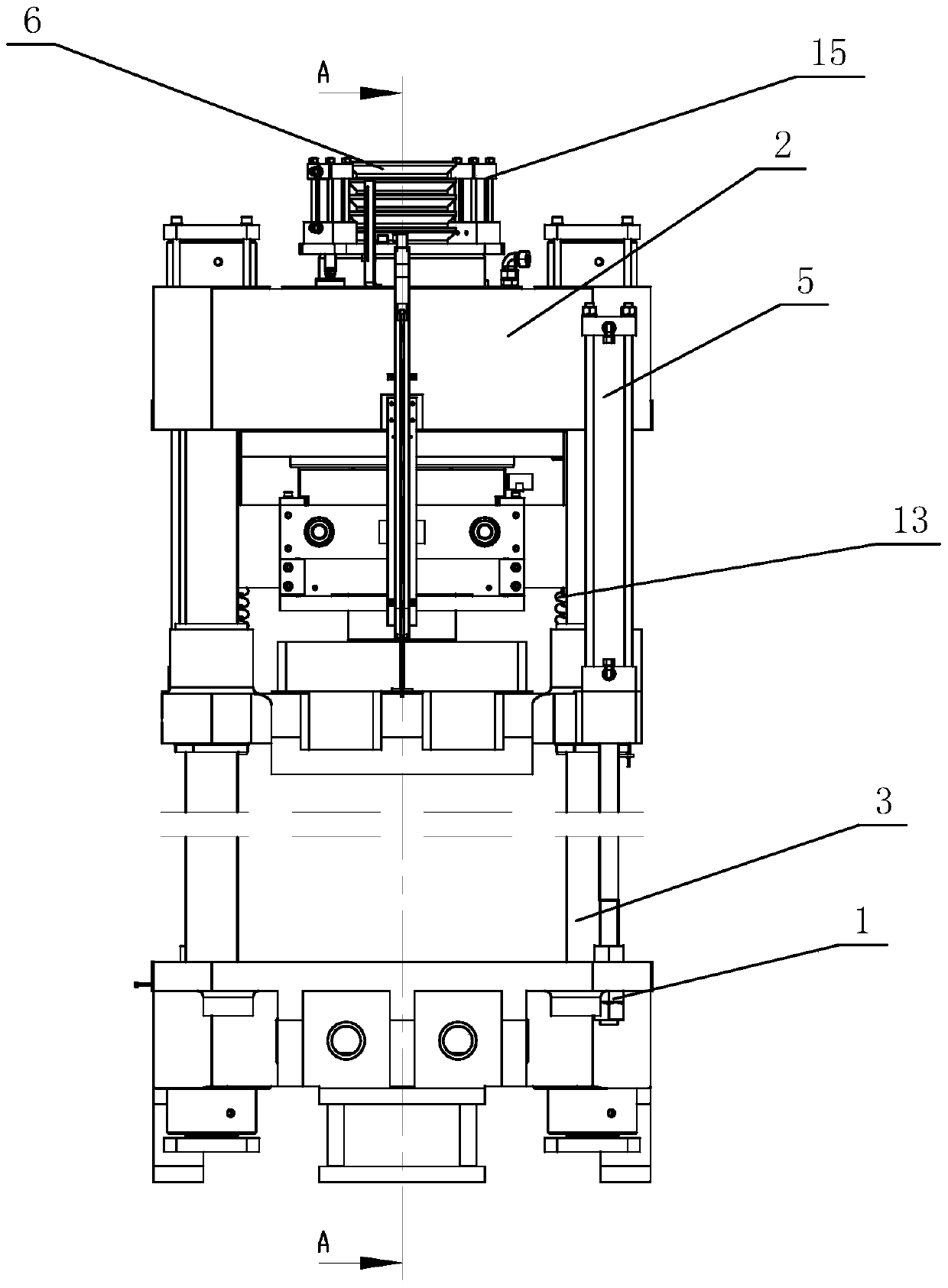

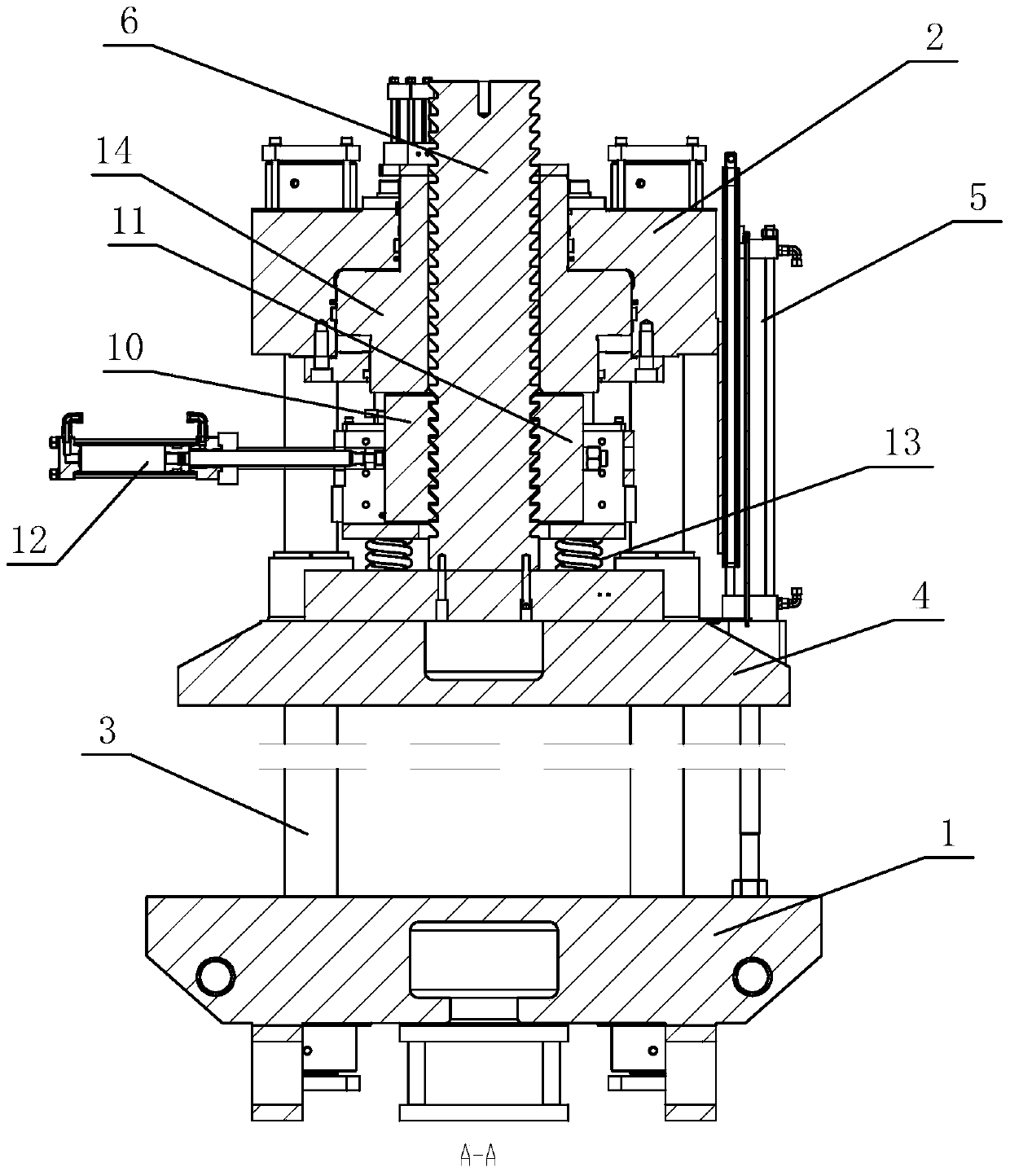

[0021] An upper moving block type pressurized mold locking mechanism of the present invention, which includes a lower template 1, an upper template 2, a column 3, a movable template 4, two quick mold clamping oil cylinders 5, and a large stud 6, and the movable template 4 passes through The column 3 can be lifted and positioned between the lower formwork 1 and the upper formwork 2, the large stud 6 is positioned on the upper formwork 2, and the lower end connects the movable formwork 4 with the column 3 as the guide to open and close up and down, and the two quick clamping cylinders 5 are fixed on the movable formwork 4. On the opposite corner, the piston rod is connected to the lower formwork 1, the upper formwork 2 is provided with a guide rod 7 extending downward, the guide rod 7 is provided with a lifting beam, and the upper formwork 2 is provided with a downwardly extending mold adjustment cylinder 8, Its piston rod connects elevating crossbeam 9, and elevating crossbeam 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com