Industrial operation control table

A console and industrial technology, applied in the direction of machine/stand, supporting machine, mechanical equipment, etc., can solve the problems of appearance change, drive gear wear and deformation, drive motor control performance cost, difficulty in controlling display angle, etc., and achieve compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

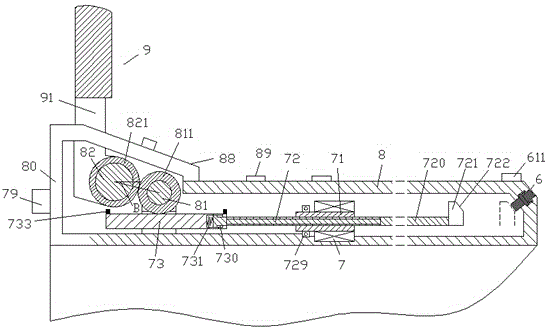

[0010] Combine below Figure 1-2 The present invention will be described in detail.

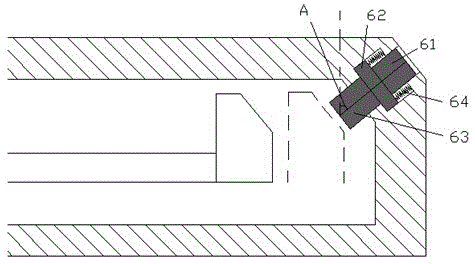

[0011] An industrial operation console according to an embodiment includes a console body 8 and a display panel 9 connected to the console body 8, wherein the console body 8 includes a housing part 80, and the housing part 80 is fixedly provided with a first shaft 81 for rotatably installing a drive pinion 811 and a shaft 81 whose level is higher than the first shaft 81 is used for rotatably installing and setting separately from the display panel 9 The two bottom legs 91 are fixedly connected to the second shaft 82 of the driven bull gear sleeve 821, wherein the driving pinion 811 meshes with the driven bull gear sleeve 821 and the number is one respectively. Both are arranged between the two bottom fixed leg parts 91, the lower side of the driving pinion 811 meshes with the rack portion on the upper side of the left and right moving block 73, and the left and right moving block 73 is near ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com