A hydraulic sludge grab

A hydraulic and sludge technology, applied in the direction of load hanging components, transportation and packaging, can solve the problems of unsatisfactory effect, easy collision damage, troublesome production, etc., to achieve not easy collision damage, good protection effect, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

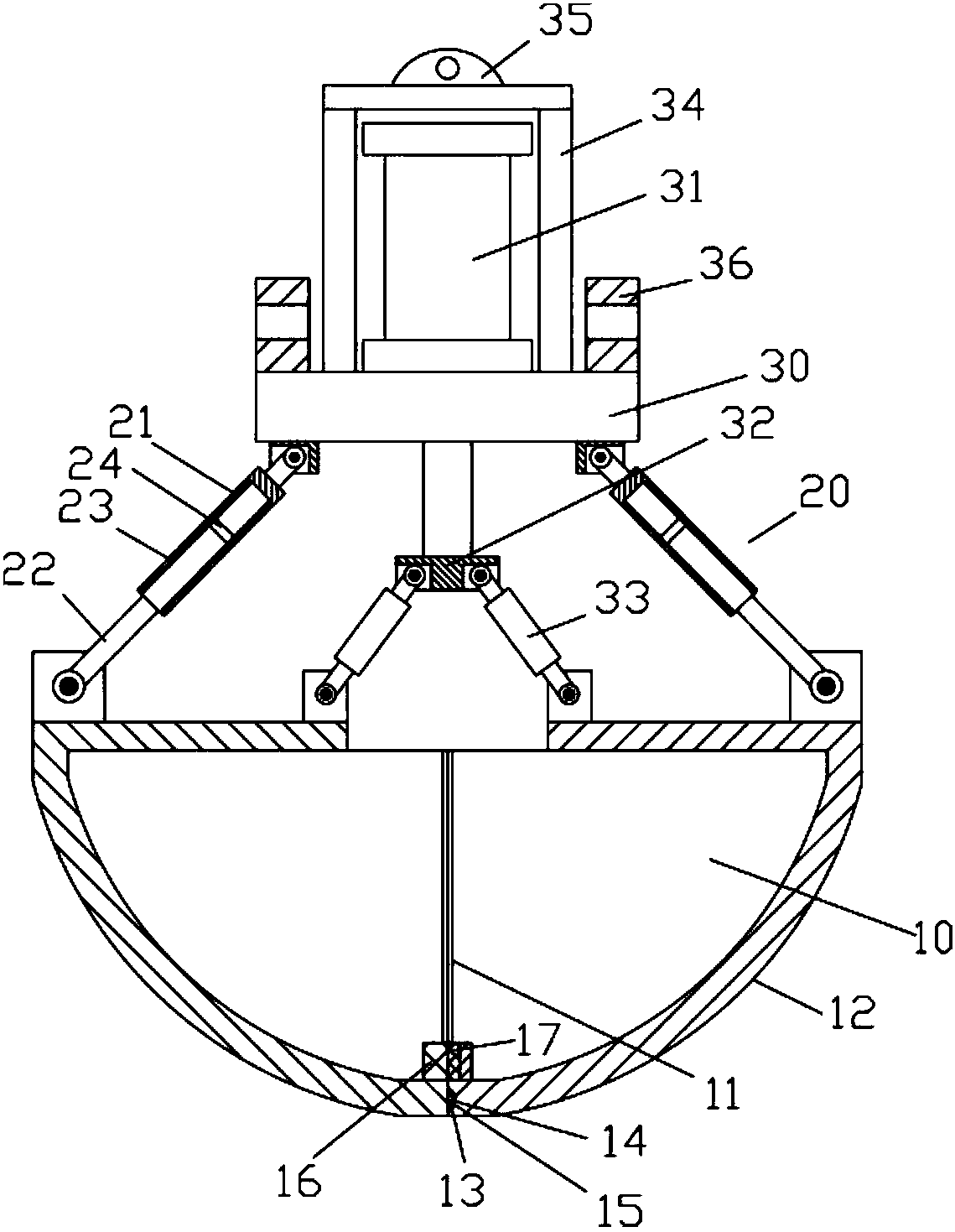

[0017] Examples, see e.g. Figure 1 to Figure 2 As shown, a hydraulic sludge grab includes two oppositely arranged buckets 10 that can be opened and closed. One end of the conveying support rod device 20 is hinged at the rear of the upper top plate of the corresponding bucket 10, and the conveying support The other end of rod device 20 is hinged on the upper connecting block 30, and the middle part top surface of upper connecting block 30 is fixed with pushing oil cylinder 31, and the push rod of pushing oil cylinder 31 passes through upper connecting block 30 and is fixed with pushing block 32 downwards, pushes The rod 33 is at the bottom of the push block 32, the upper ends of the two push rods 33 are respectively hinged at the bottom of both ends of the push block 32, and the other ends of the two push rods 33 are respectively hinged at the front part of the upper top plate of the corresponding bucket part 10 ;

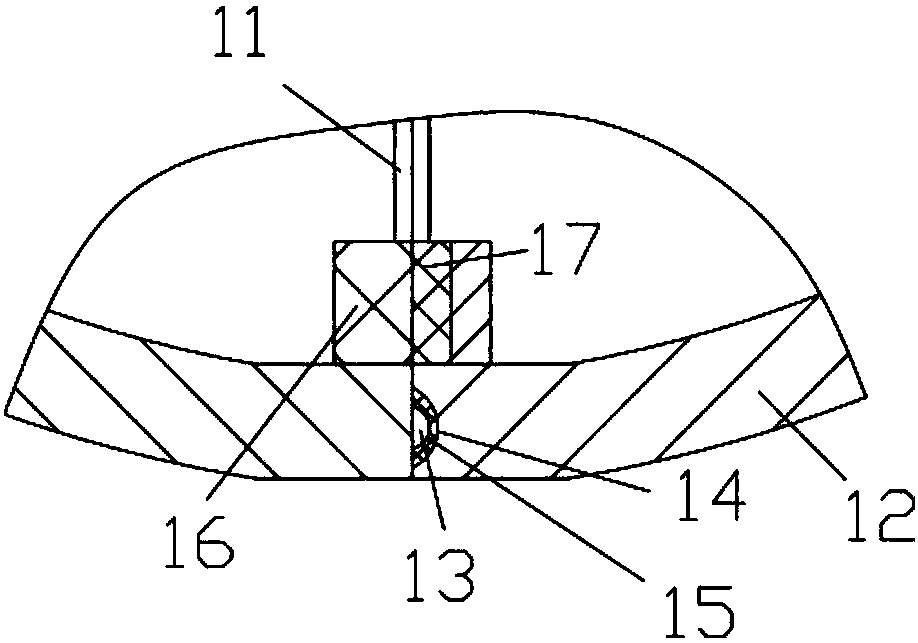

[0018] A buffer layer 11 is fixed on the contacting end surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com